Method of preparing taxol by separating 10-deacetyl taxol acylate

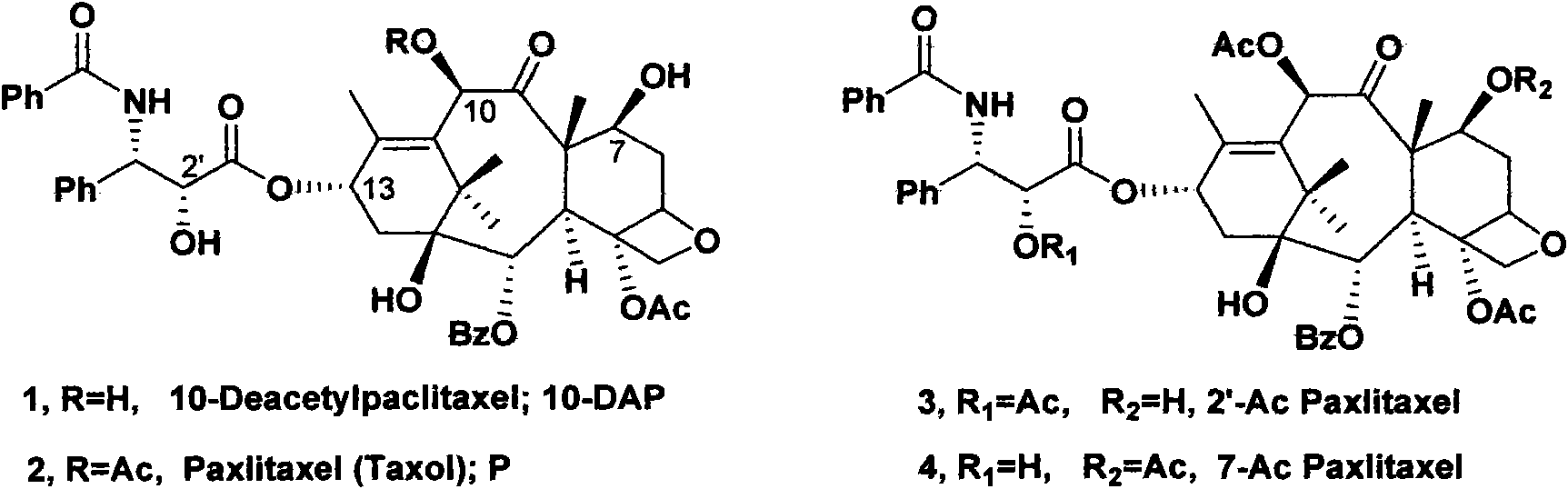

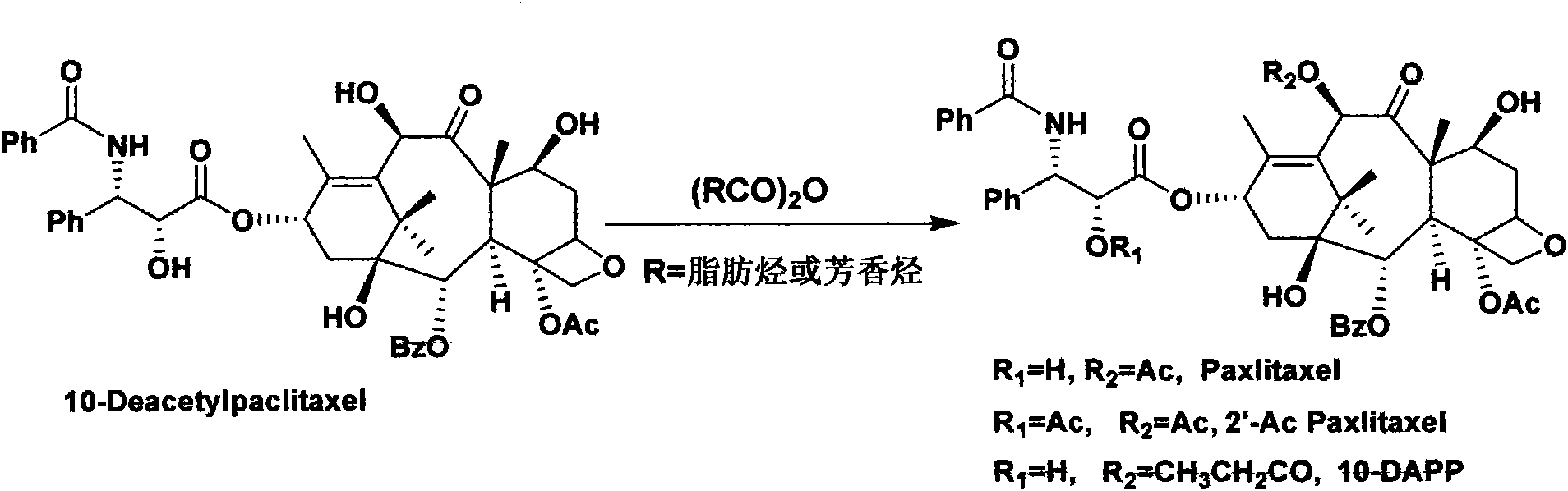

A technology for deacetylpaclitaxel and acylated products, which is applied in the direction of organic chemistry and the like, and achieves the effects of high preparation efficiency, low solvent consumption, high reproducibility and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A high-efficiency countercurrent chromatography system with a column volume of 25 mL was used to configure n-hexane-ethyl acetate-methanol-water in proportion, and the corresponding volume ratios were: 0.9:1:0.9:1 and n-hexane-ethyl acetate-methanol-water, The corresponding volume ratio is: 0.9: 1: 0.9: 0.8, shake well and let stand to separate layers. Separate the upper and lower layers for later use.

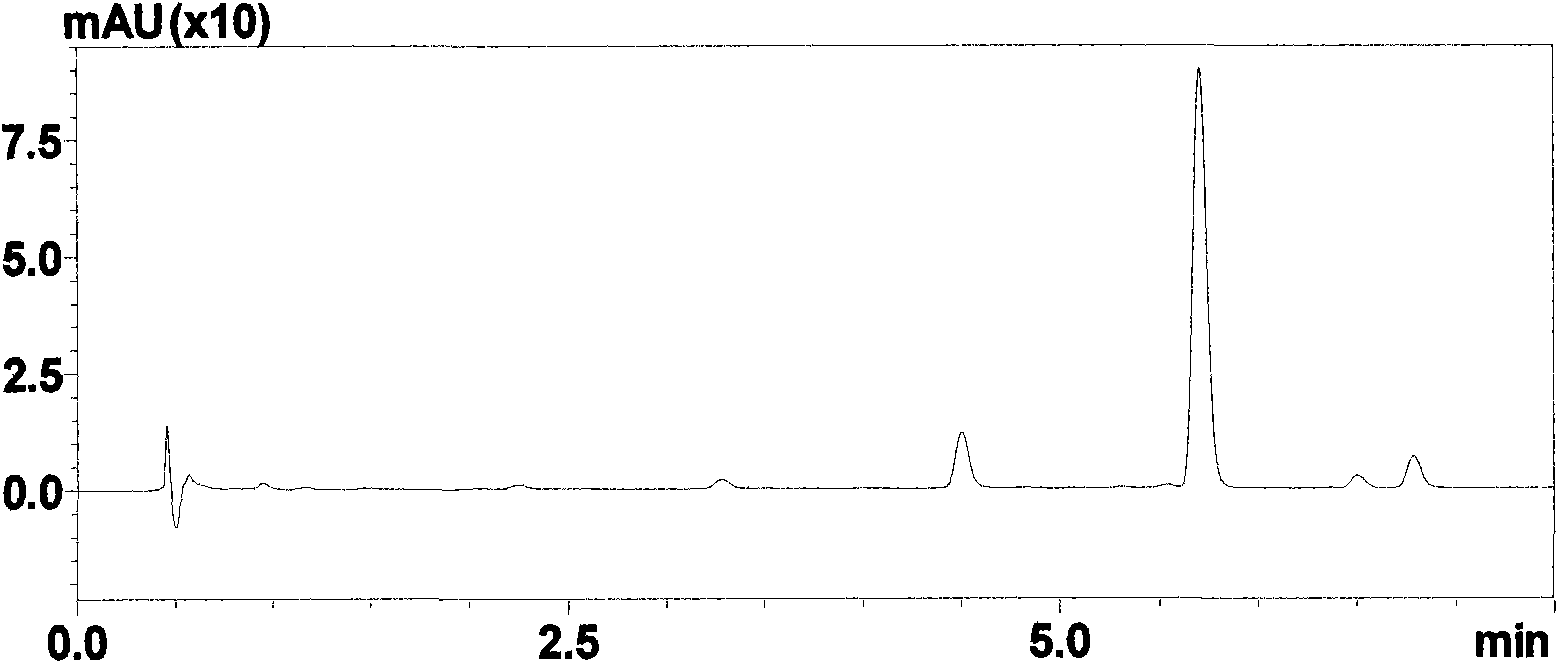

[0027] Weigh 20 mg of 10-deacetylpaclitaxel acylation product containing 92% paclitaxel, and dissolve it in 2 mL of solvent for use. Before sample injection, fill the entire column with the upper layer of solvent system I, adjust the speed of the main engine to 1600rpm, pump the lower layer of solvent system I into the column, and inject the sample after dynamic equilibrium; detect the product at 230nm, receive the target component and The solvent system was switched (I to II) when paclitaxel reached its peak (14-16 minutes). After the target fraction was evaporated t...

Embodiment 2

[0029] A high-efficiency countercurrent chromatography system with a column volume of 134 mL was used to configure n-hexane-ethyl acetate-methanol-water in proportion, and the corresponding volume ratios were: 0.9:1:0.9:1 and n-hexane-ethyl acetate-methanol-water, The corresponding volume ratio is: 0.9: 1: 0.9: 0.8, shake well and let stand to separate layers. Separate the upper and lower layers for later use.

[0030] Weigh 100 mg of 10-deacetylpaclitaxel chemical acylation product containing 70% paclitaxel, and dissolve it in 10 mL of solvent for use. Before sample injection, fill the entire column with the upper layer of solvent system I, adjust the speed of the main engine to 1600rpm, pump the lower layer of solvent system I into the column, and inject the sample after dynamic equilibrium; detect the product at 230nm, receive the target component and When the paclitaxel peaked (14-16 minutes), the solvent system was switched (I to II). The white solid of paclitaxel was o...

Embodiment 3

[0032] A high-efficiency countercurrent chromatographic system with a column volume of 2.5L is used to configure n-hexane-ethyl acetate-methanol-water in proportion, and the corresponding volume ratios are: 0.9:1:0.9:1 and n-hexane-ethyl acetate-methanol-water , the corresponding volume ratio is: 0.9:1:0.9:0.8, shake well and let stand to separate layers. Separate the upper and lower layers for later use.

[0033] Weigh 2 grams of 10-deacetylpaclitaxel chemical acylation product containing 85% paclitaxel, and dissolve it in 200 mL solvent for use. Before sample injection, fill the entire column with the upper layer of solvent system I, adjust the speed of the main engine to 1600rpm, pump the lower layer of solvent system I into the column, and inject the sample after dynamic equilibrium; detect the product at 230nm, receive the target component and When the paclitaxel peaked (14-16 minutes), the solvent system was switched (I to II). The white solid of paclitaxel was obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com