Preparation method of anti-counterfeit paint with property of multiple optics frequency conversion and anti-counterfeit detection method

A frequency conversion and optical technology, applied in the field of preparation and detection of new multi-optical frequency conversion anti-counterfeiting coatings, can solve problems such as poor concealment, and achieve the effects of multiple anti-counterfeiting features, wide applicable temperature range and unchanged frequency conversion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of novel multiple optical frequency conversion anti-counterfeiting coating

[0031] The steps are as follows: 1. 35% SiO 2 , 17%B 2 o 3 , 18%Na 2 CO 3 , 1%Ba(OH) 2 , 3% Er 2 o 3 , 24%Yb 2 o 3 , 2%Nd 2 O3 (mass fraction) mixed; 2. Take 20g of the mixture and put it into a 30ml corundum crucible; 3. Place the corundum crucible in a high-temperature furnace, and first heat it up from room temperature to 600°C at a speed lower than 7°C / min, and then heat it up at a low temperature. Raise the temperature to 1200°C at a rate of 5°C / min, keep it warm for 60 minutes, then turn off the power of the high-temperature furnace, and take out the crucible; 4. Pour the molten substance in the crucible into cold water to cool; 5. Put the cooled substance in a In the planetary ball mill, ball mill at a speed of 450 rpm for 60 minutes to make a powder of 1-10 microns; 6. Mix the powder with ink in a ratio of 1:10 to make multiple optical frequency conversi...

Embodiment 2

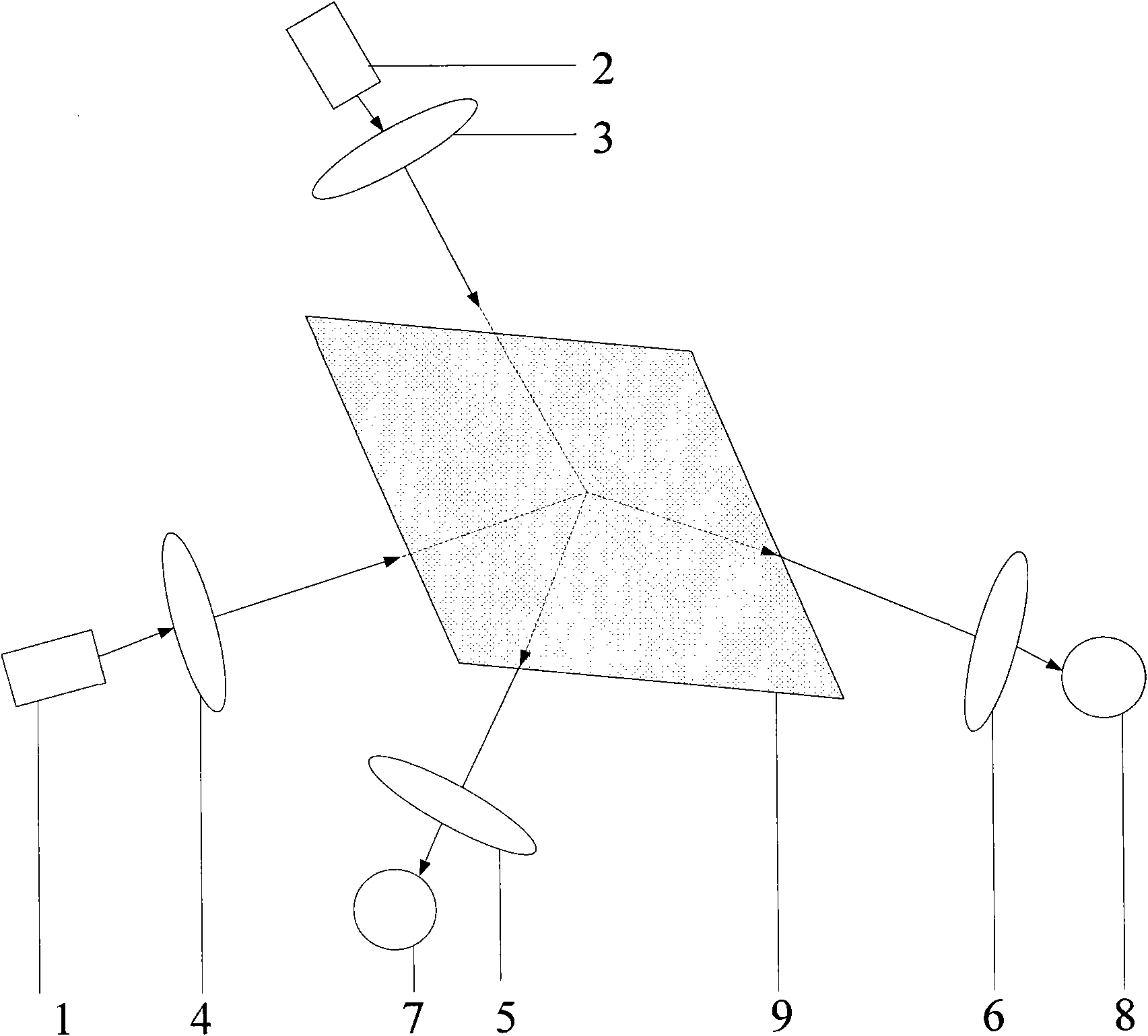

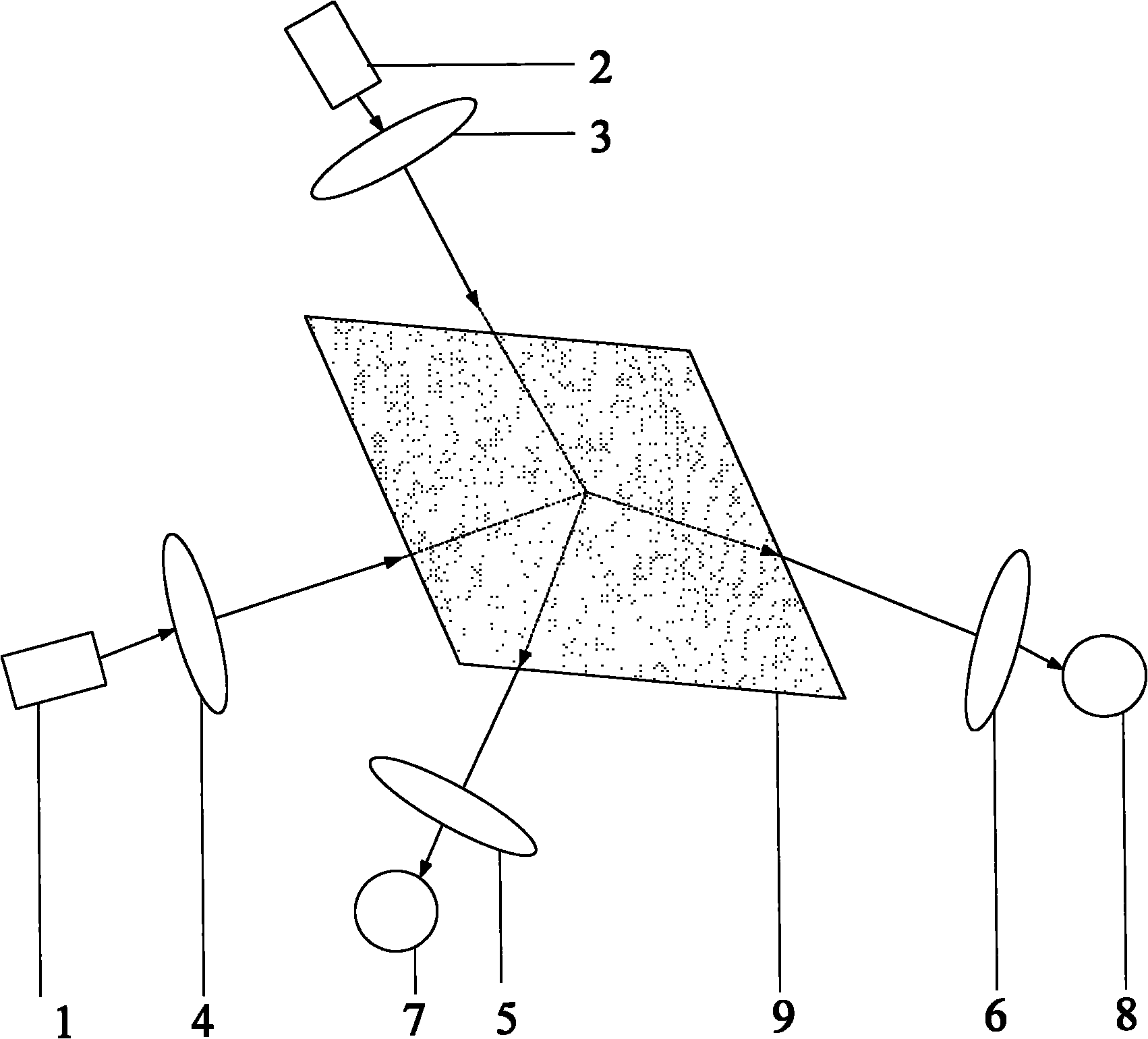

[0032] Example 2: Detecting the anti-counterfeiting properties of the novel multiple optical frequency conversion anti-counterfeiting coating

[0033] Detection methods such as figure 1 As shown, one, the novel multiple optical frequency conversion anti-counterfeiting coating prepared in embodiment 1 is coated on the object to be tested; two, the 980nm laser light emitted by the light emitting chip 1 is collimated and focused by the collimating lens 4 and hits the object to be tested. On the measured object 9, the frequency of the excited light is 1550nm, after being focused and filtered by the 1550nm filter lens 6, it enters the light receiving chip 8, and the signal indicator lights up; After focusing directly on the object 9 to be tested, the frequency of the excited light is 1060nm, after being focused and filtered by the 1060nm filter lens 5, it enters the light receiving chip 7, and the signal indicator lights up; The measured object is "true" (other cases are "false")....

Embodiment 3

[0034] Embodiment 3, low temperature stability test of multiple optical frequency conversion anti-counterfeiting coating

[0035]The coating preparation method is the same as Example 1, but the replacement condition is: the coating prepared in Example 1 is taken out after being frozen at a temperature of -30° C. for 8 hours, and its frequency conversion characteristics are measured immediately. It is found that its characteristics are the same as Example 1. The frequency conversion performance of the invention remains unchanged under low temperature conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com