Cavity surface film coating method for improving temperature stability of semiconductor laser

A technology of lasers and semiconductors, applied in semiconductor lasers, lasers, devices for controlling laser output parameters, etc., can solve problems such as increase and reduction of laser slope efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

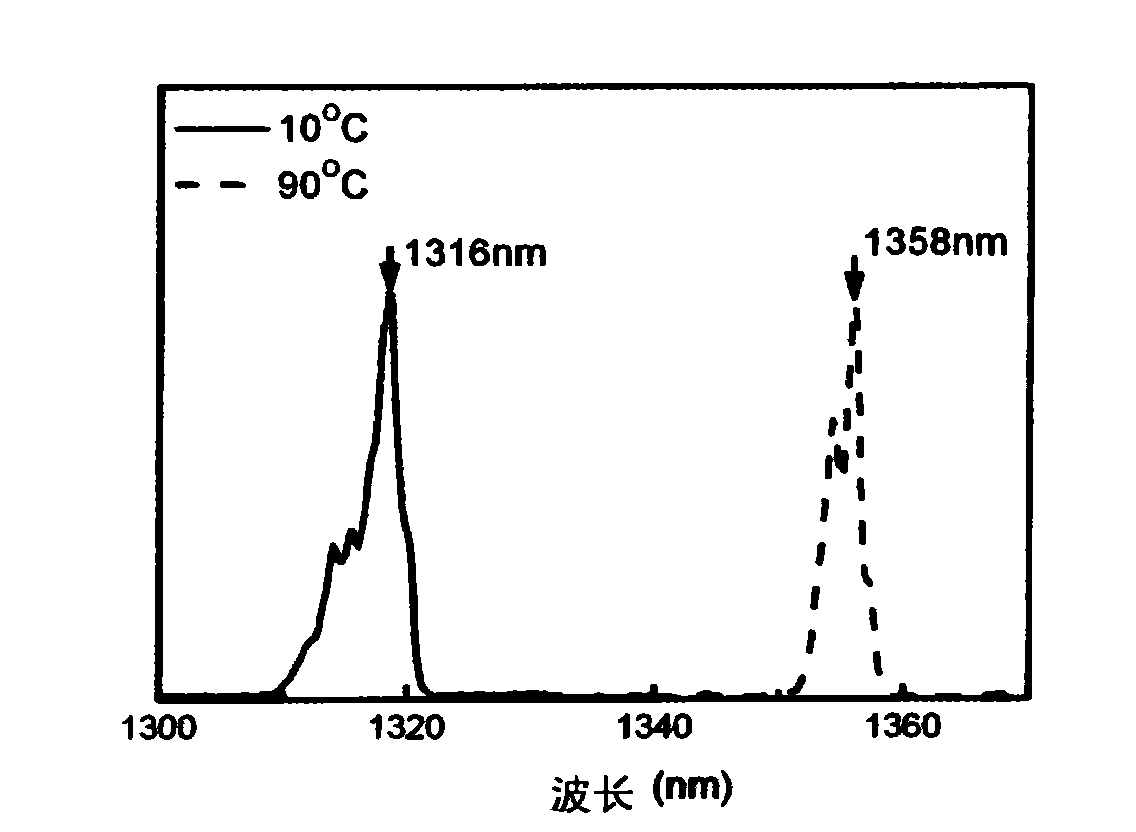

[0018] Step 1: Take a cleaved InAs / GaAs semiconductor quantum dot laser chip; its lasing wavelength increases linearly with increasing temperature, and the lasing wavelengths at 10°C and 90°C are about 1316nm and 1358nm respectively (see figure 1 ).

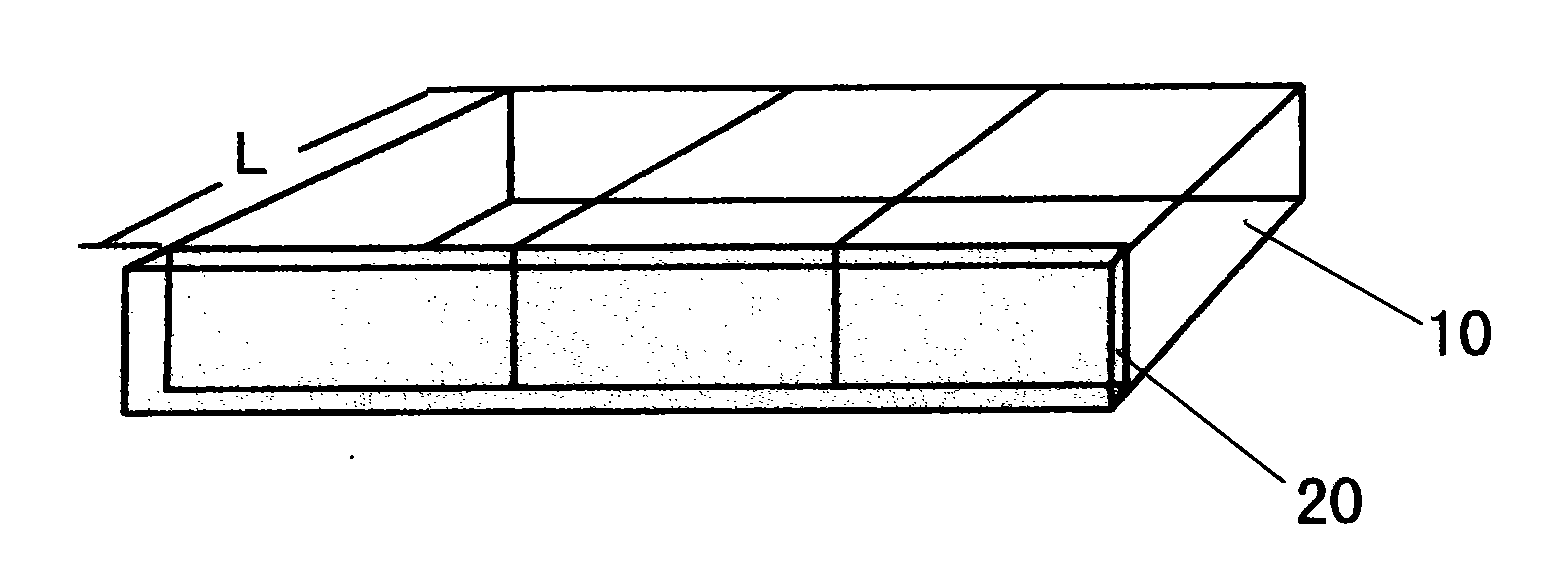

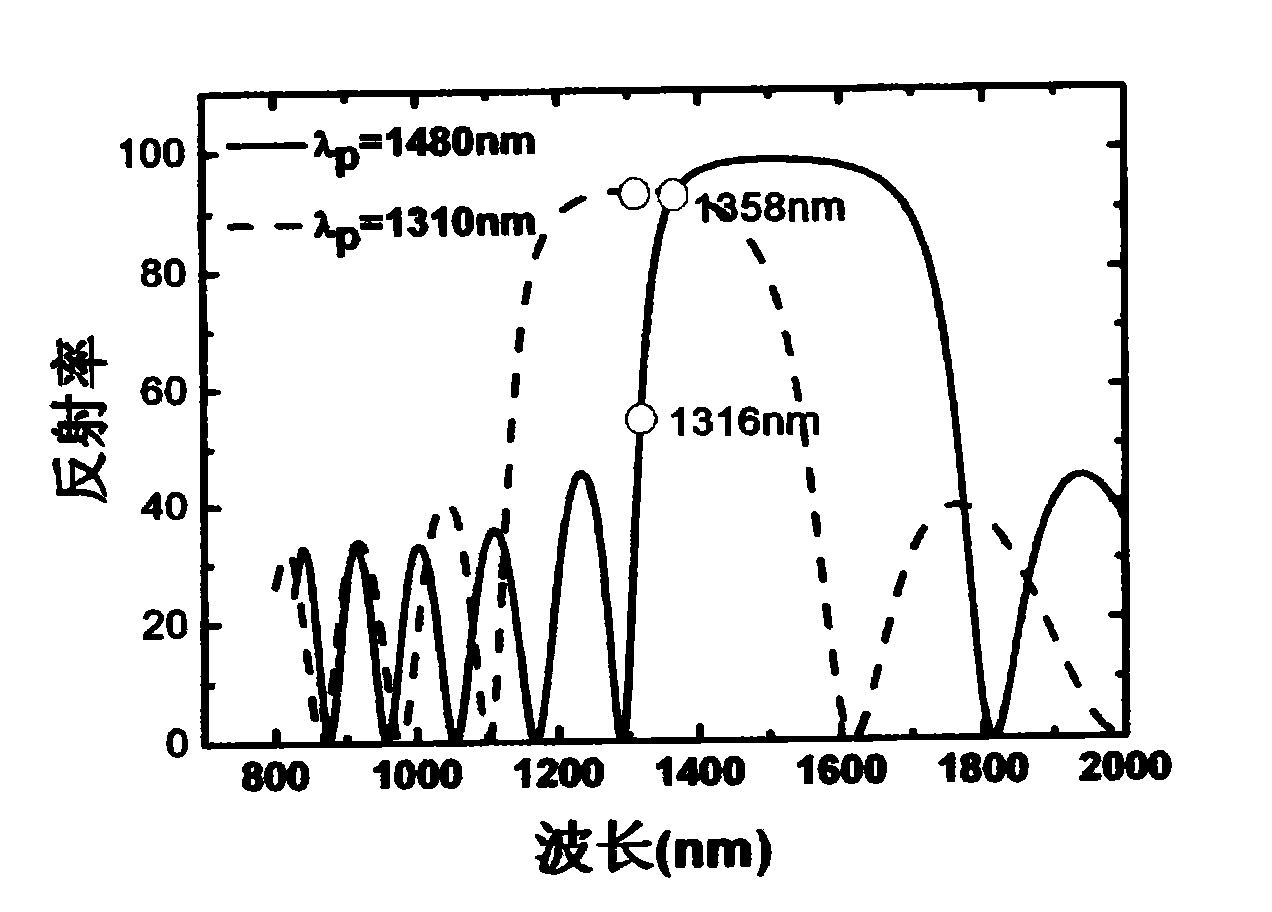

[0019] Step 2: Alternately depositing Ta with an optical thickness of λ / 4 on the rear end face of the semiconductor laser chip 10 2 o 5 / SiO 2 Thin film, on the wavelength-reflectance curve, a thin film system 20 whose reflectance increases with the wavelength red shift is obtained, and the other end is used as the exit cavity surface of the laser without coating. Semiconductor quantum dot laser chip after cavity surface coating such as figure 2 shown. Among them Ta 2 o 5 is a high refractive index material, SiO 2 It is a low refractive index material. The central wavelength of the thin film system 20 is 1480 nm. The wavelength-reflectance curve obtained by the coating is as follows image 3 As shown by the middle soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com