Integrated high-voltage intelligent phase selection permanent-magnetic circuit breaker

A permanent magnet circuit breaker, an intelligent technology, applied in circuit devices, emergency protection circuit devices, emergency protection devices with automatic disconnection, etc., can solve problems such as inability to use the power grid, large inrush current, and inability to maintain constant power supply quality of the power grid, etc. To achieve the effect of convenient replacement and maintenance, accurate switching phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

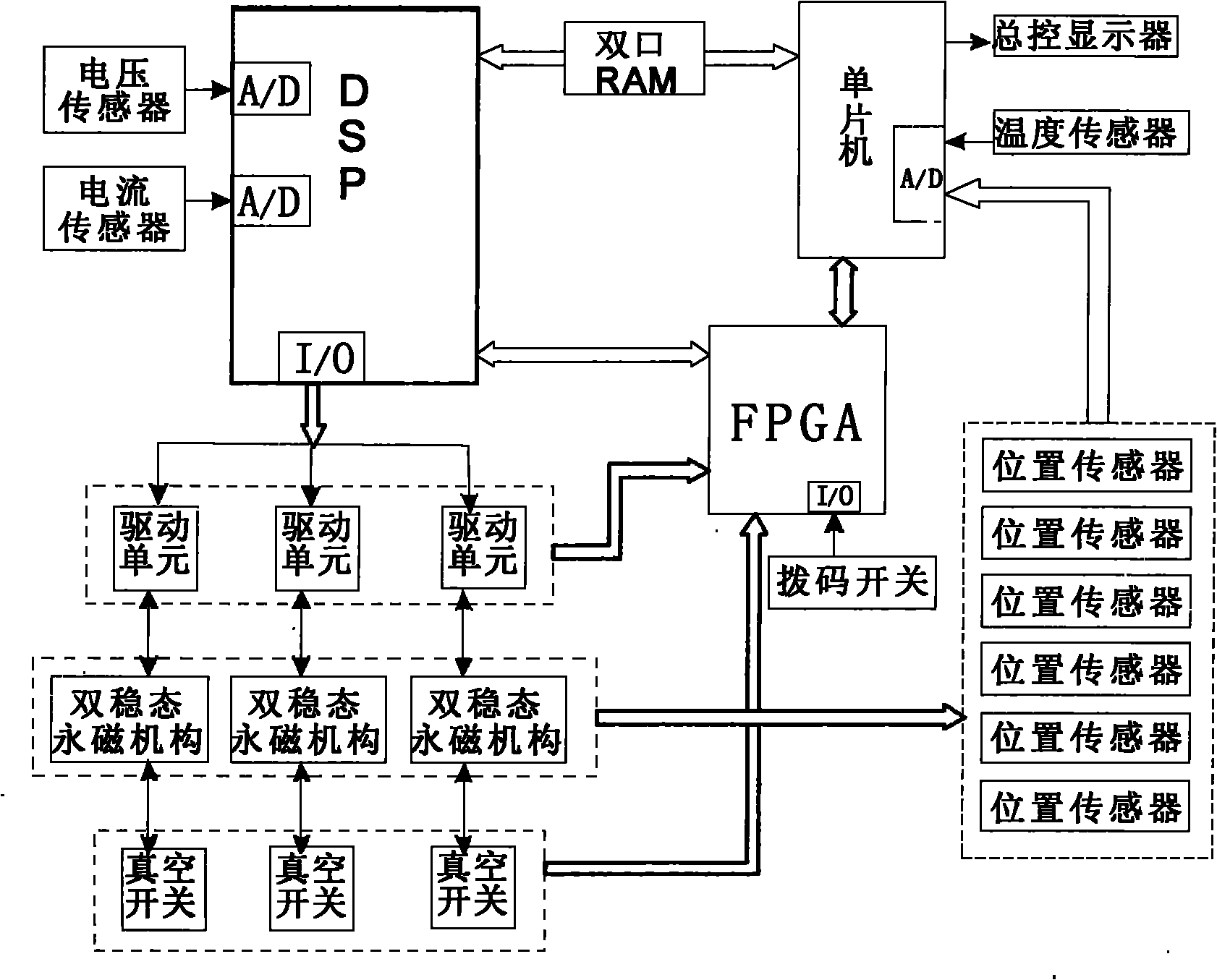

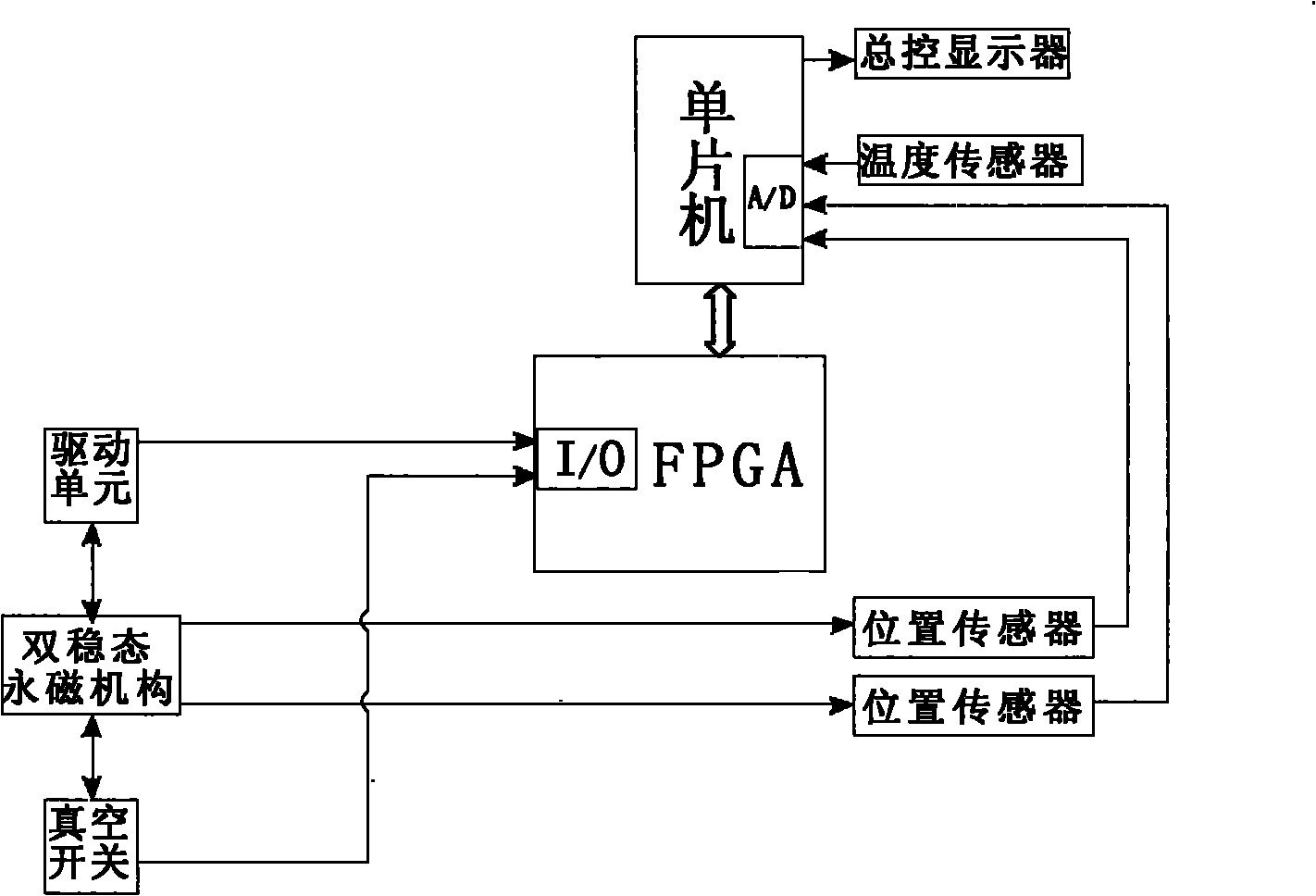

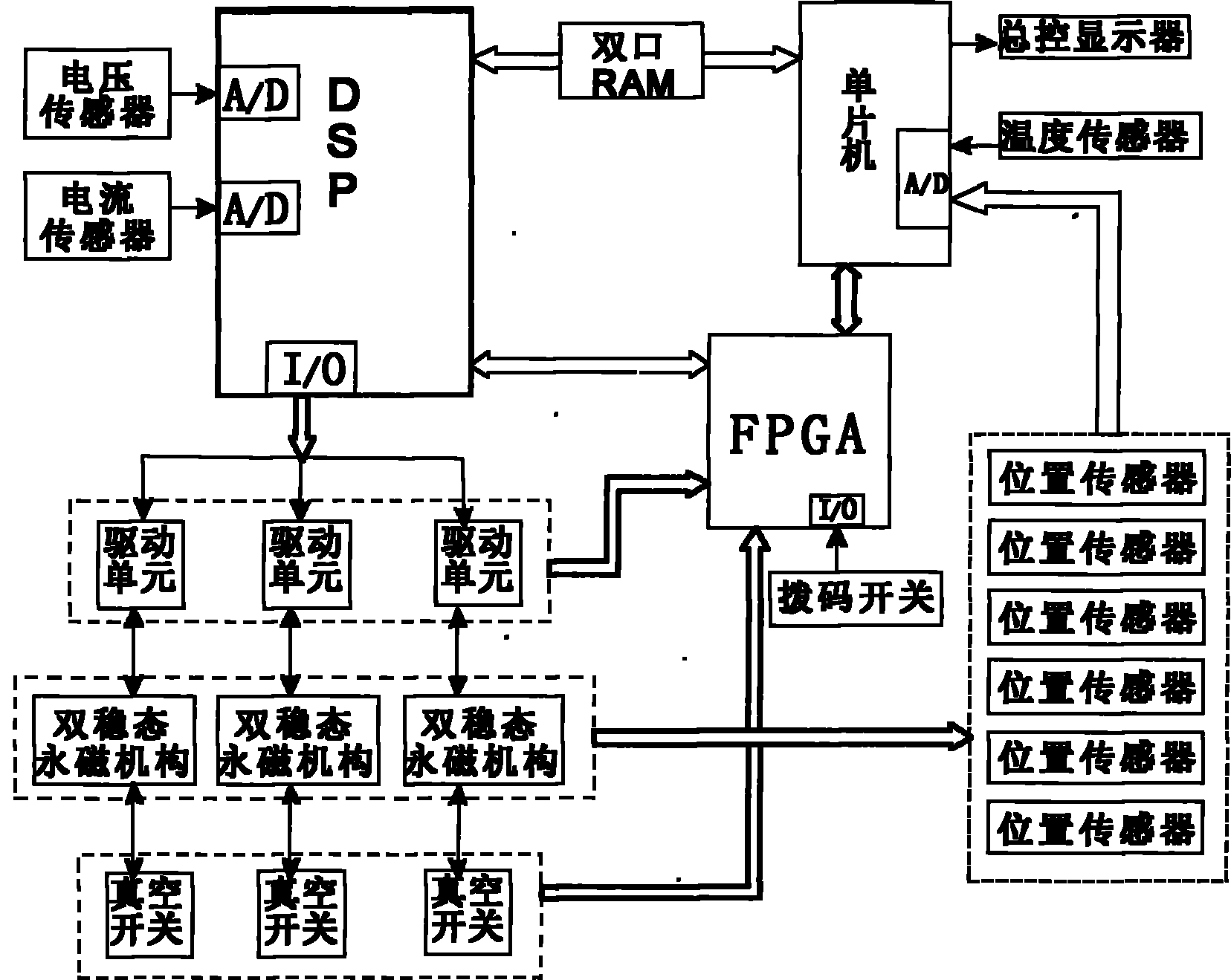

[0027] Example: see figure 1 , figure 2 , the present invention includes a controller, a master control display, a voltage sensor, a current sensor, a drive unit, an actuator and a vacuum switch, and the drive unit, the actuator and the vacuum switch are serially connected in series to form a set of controlled controls,

[0028] It also includes a temperature sensor, the controlled units are three groups, and the actuator is a bistable permanent magnet mechanism, and there are two position sensors on the driving mechanism of any bistable permanent magnet mechanism, and the bistable permanent magnet The mechanism is a very stable electromagnetic drive mechanism, which has few mechanical components, reliable operation, and very low energy consumption. Its biggest advantage is that with the cooperation of a good drive circuit, its motion characteristics are very stable. After thousands of operations, its The parameter drift is small,

[0029] The drive unit adopts a high-preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com