Novel power circuit of high-voltage SRD (Step Recovery Diode)

A power circuit, a new type of technology, applied in the direction of electrical components, AC motor control, single motor speed/torque control, etc., can solve the problem of IGBT voltage equalization that is difficult to overcome, high-voltage SRD can not be applied, etc., to achieve low cost and high power consumption. Less electronic components and simple circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

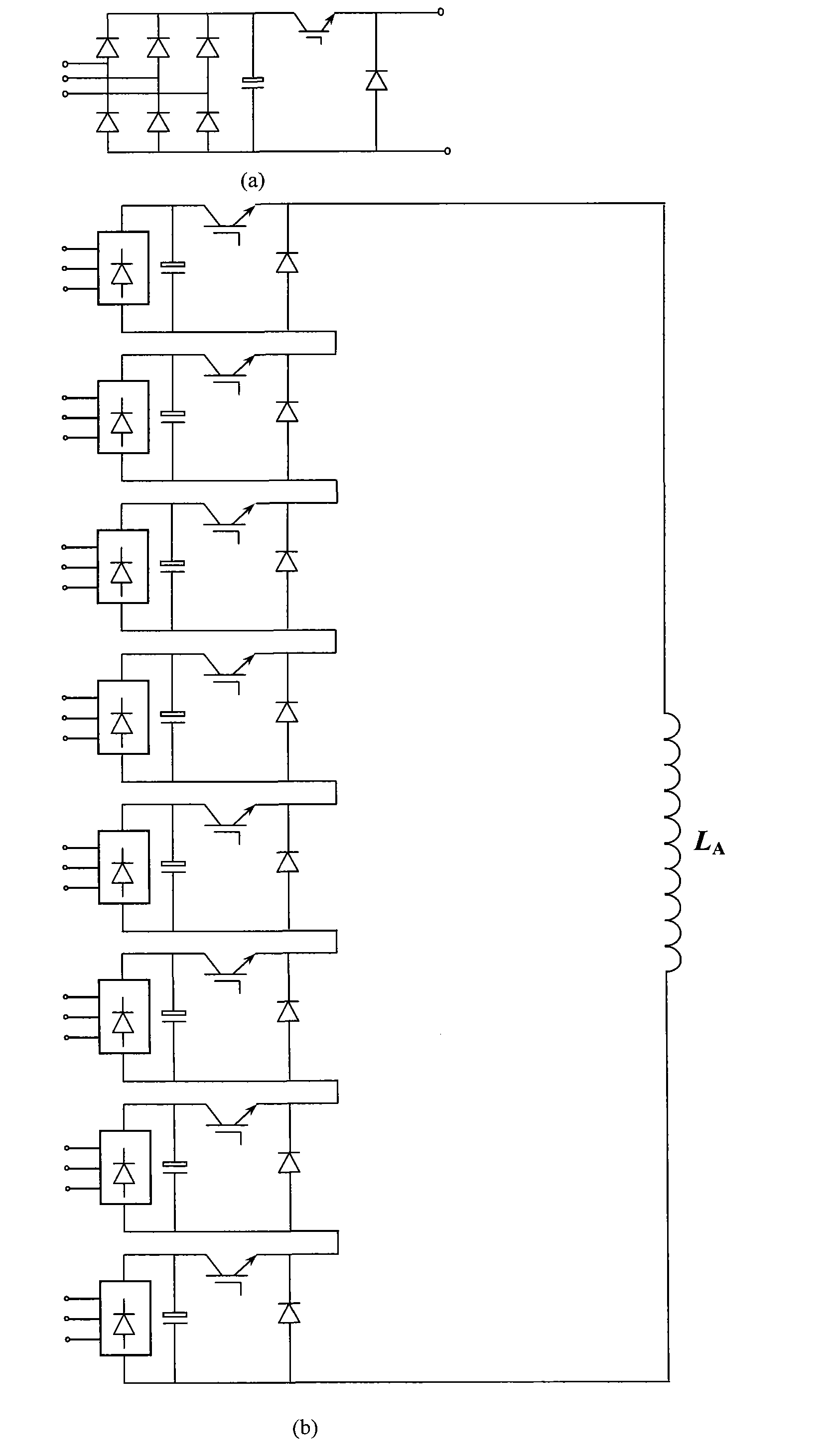

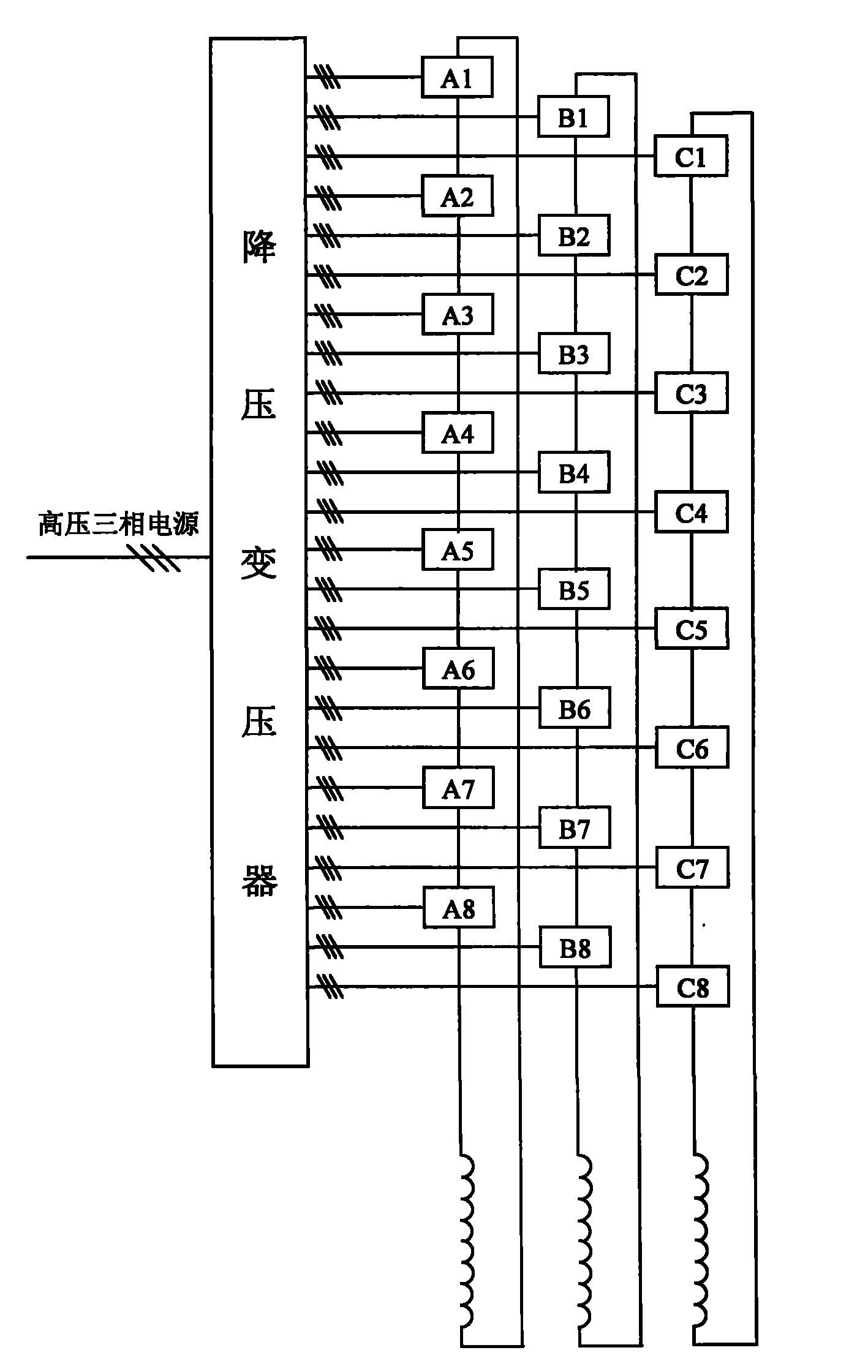

[0018] combined with image 3 Set forth specific embodiment 1 of the present invention: step-down transformer once connects high-voltage three-phase power supply, step-down transformer secondary 24 angle-connected windings are respectively connected with (A 1 …A 8 ), (B 1 …B 8 )(C 1 …C 8 ) 24 power unit three-phase input terminals are connected. (A 1 …A 8 ) indicates that the voltage after the output ends of the eight power units are connected in series is applied to the A-phase winding L of the SR motor A . Similarly, the 8 power units of the other two phases are connected in series and respectively added to the B-phase winding L of the SR motor B and C-phase winding L C . If the primary high voltage is 6KV (10KV), the voltage drop of the secondary corner extension winding is 530V (890V). After three-phase bridge rectification and filtering, the DC output voltage is 750V (1250V) and then pulse width modulated by the power electronic component IGBT. The output volt...

specific Embodiment 2

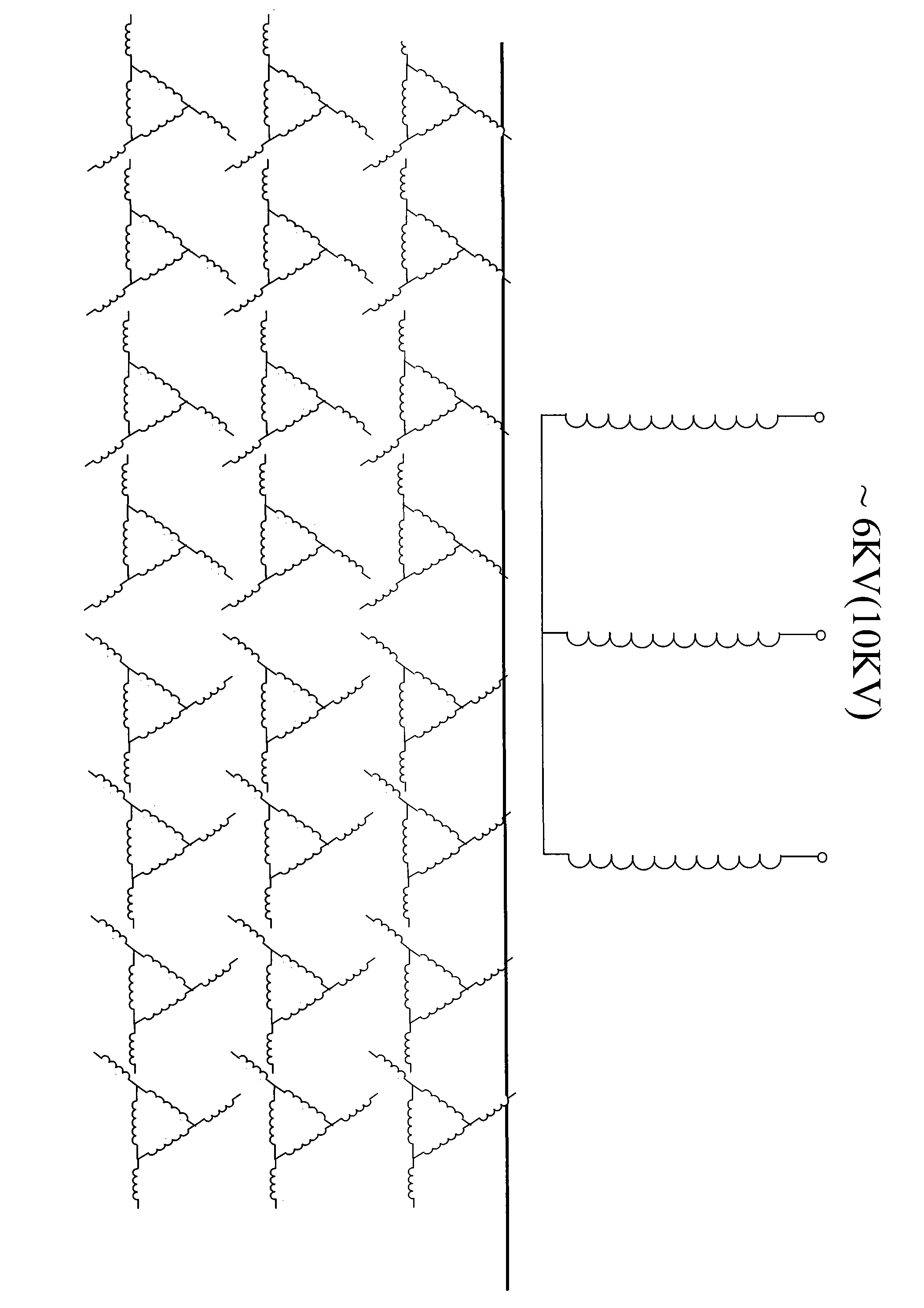

[0019] combined with Figure 4 Describe the specific embodiment 2 of the present invention: the step-down transformer is connected to the high-voltage three-phase power supply at the first time, and the transformer is only provided with 8 corner-connected windings at the secondary stage, and the three-phase input terminals of the 8 power units are connected with 8 corner-connected three-phase windings , the IGBTs that supply power to the A-phase, B-phase and C-phase windings of the SR motor are all connected in parallel on the DC side of the same three-phase bridge rectifier filter circuit. If the primary high voltage is 6KV (10KV), the voltage drop of the secondary extension corner winding is 530V (890V); the same as embodiment 1, the voltage added to the three-phase winding of the SR motor is 0 to 6KV (0 to 10KV) adjustable voltage, This also adjusts the SR motor speed.

Embodiment 2

[0020] Compared with the wiring diagram of embodiment 1, the wiring diagram of embodiment 2 has the advantage that the number of secondary windings of the step-down transformer is reduced from 24 to 8, and the number of outgoing lines is reduced from 72 to 24; at the same time, the rectification and filtering elements are also reduced, but with The disadvantage is that the primary side harmonics of the step-down transformer pollute the grid, and the power factor is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com