Water-holding material and water-absorbing gel composition excellent in light resistance

A technology of water-absorbing gel and water-retaining agent, which is applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor stability, inability to maintain the shape of the gel, and insufficient light resistance of the gel, and achieve excellent water quality. The effect of high dispersibility and water retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

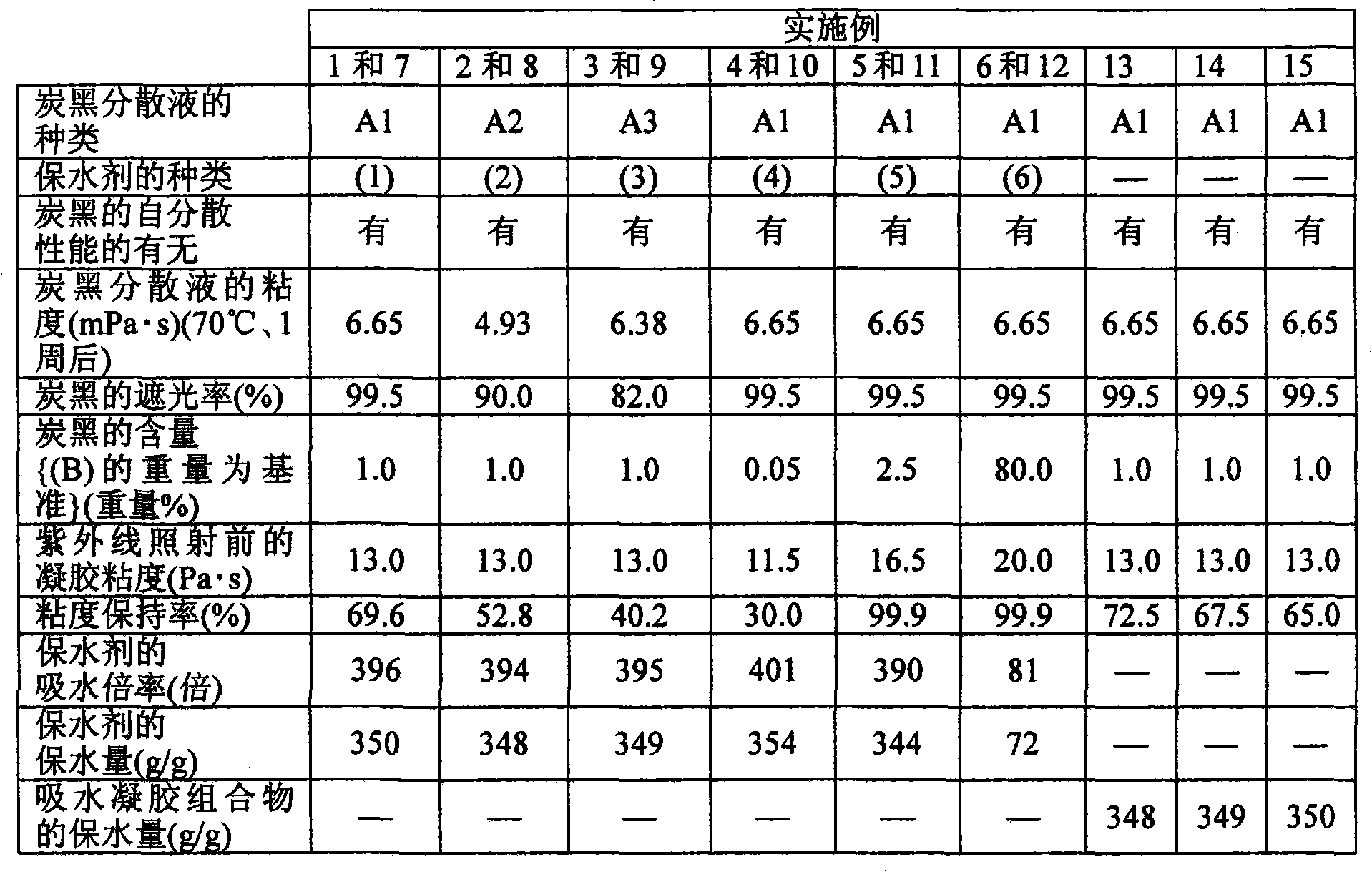

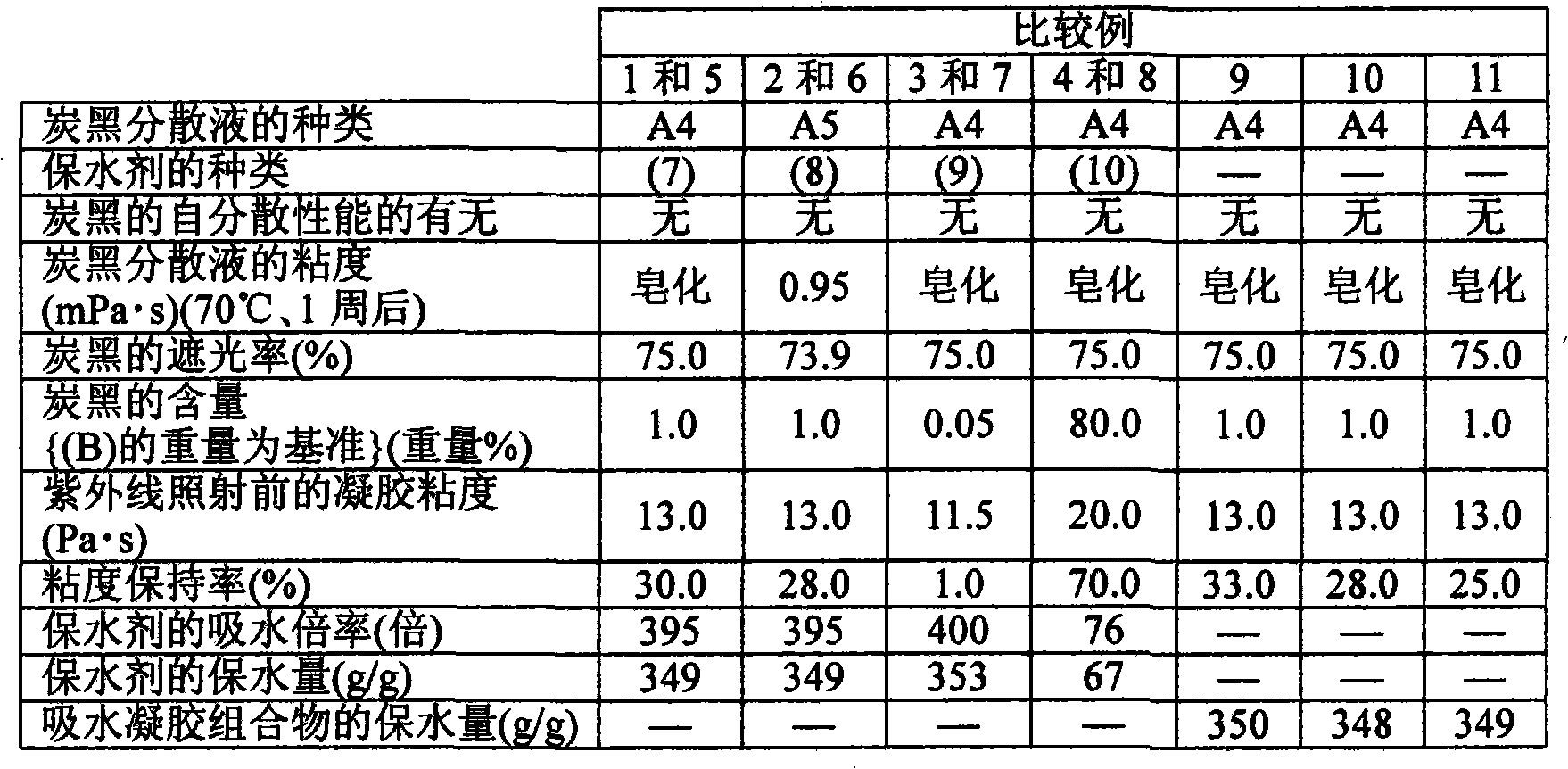

[0038] (Preparation of carbon black-containing water-absorbent resin)

[0039] While stirring 300 parts by weight of ion-exchanged water with a homomixer (2000 rpm), 0.1 part by weight of carbon black (A) having self-dispersing properties in water was added to prepare a carbon black dispersion. Then, while stirring the carbon black dispersion (2000 rpm), 10 parts by weight of a water-absorbent resin (a water-absorbent resin composed of a cross-linked polymer of a sodium acrylate salt and having a water absorption capacity of 400 g / g of ion-exchanged water) was added. (For example, Sunfresh (サンフレツシyu) (registered trademark) GT-1) manufactured by Sanyo Chemical Industry Co., Ltd. (Sanyo Chemical Industry Co., Ltd.)), a water-absorbing gel composition was prepared. The obtained water-absorbent gel composition was put into a circulating air dryer and dried at 120° C. for 3 hours to obtain a carbon black-containing water-absorbent resin.

[0040] (Detection of shading rate)

[00...

manufacture example 1

[0128] Cetyltrimethylammonium bromide adsorption specific surface area (CTAB) 140m 2 Carbon black (1) having an absorption value of 128 ml / 100 g of / g and DBP (dibutyl phthalate) was subjected to oxidation treatment to obtain oxidized carbon black. The oxidation treatment is to add 100 g of carbon black to a concentration of 1.0 mol / dm 3 Aqueous solution of sodium peroxodisulfate 3dm 3 , the reaction temperature is 60°C, the reaction time is 10 hours, and the stirring speed is 0.12s -1 conditions.

[0129] After the reaction is completed, the oxidized carbon black and the reaction solution are filtered and separated, and the oxidized carbon black with a concentration of 1.0 mol / dm 3 neutralized with an aqueous sodium hydroxide solution. After neutralization, a centrifugal separator (manufactured by Hitachi Koki (Hitachi Koki), CR22F) was used at 7.5×10 -3 S -1 , 15 minutes for classification treatment. Then, the supernatant was separated from the remaining salt with an ...

manufacture example 2

[0131] A carbon black dispersion liquid (A2) having a dispersion concentration of 20% by weight was produced in the same manner as in Production Example 1, except that the classification treatment in Production Example 1 was not performed. The viscosity of the carbon black dispersion liquid (A2) at 25°C (after standing at 70°C for 1 week) was 4.93 mPa·s, and the carbon black (a2) in (A2) already had self-dispersion performance. The light-shielding ratio of (a2) was 90.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com