Water-holding material and water-absorbing gel composition excellent in light resistance

A water-retaining agent and water-absorbing technology, used in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor stability, inability to maintain the shape of gel-like substances, insufficient light resistance of the gel, etc., and achieve high water-retention capacity. , the effect of excellent water dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

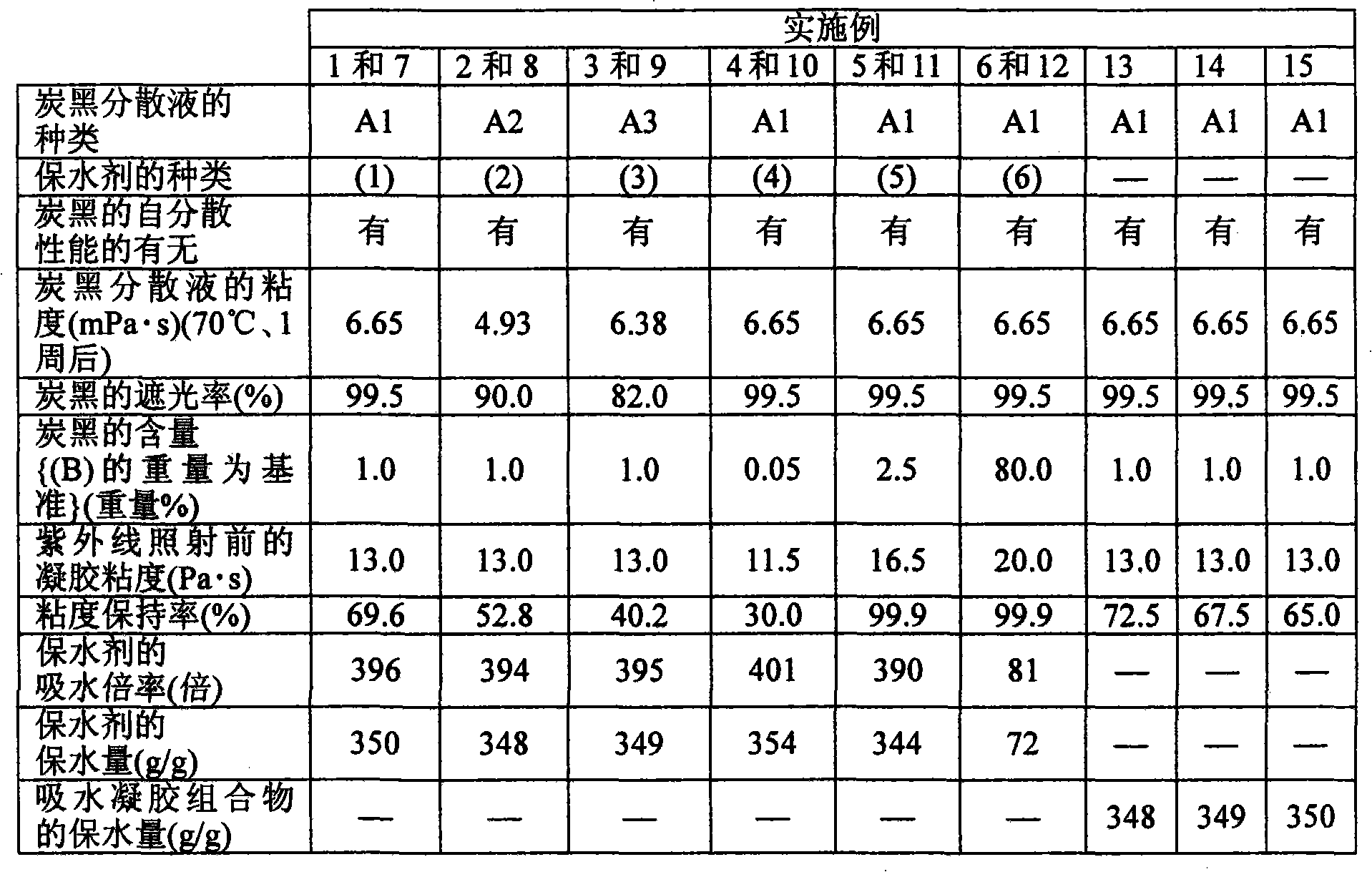

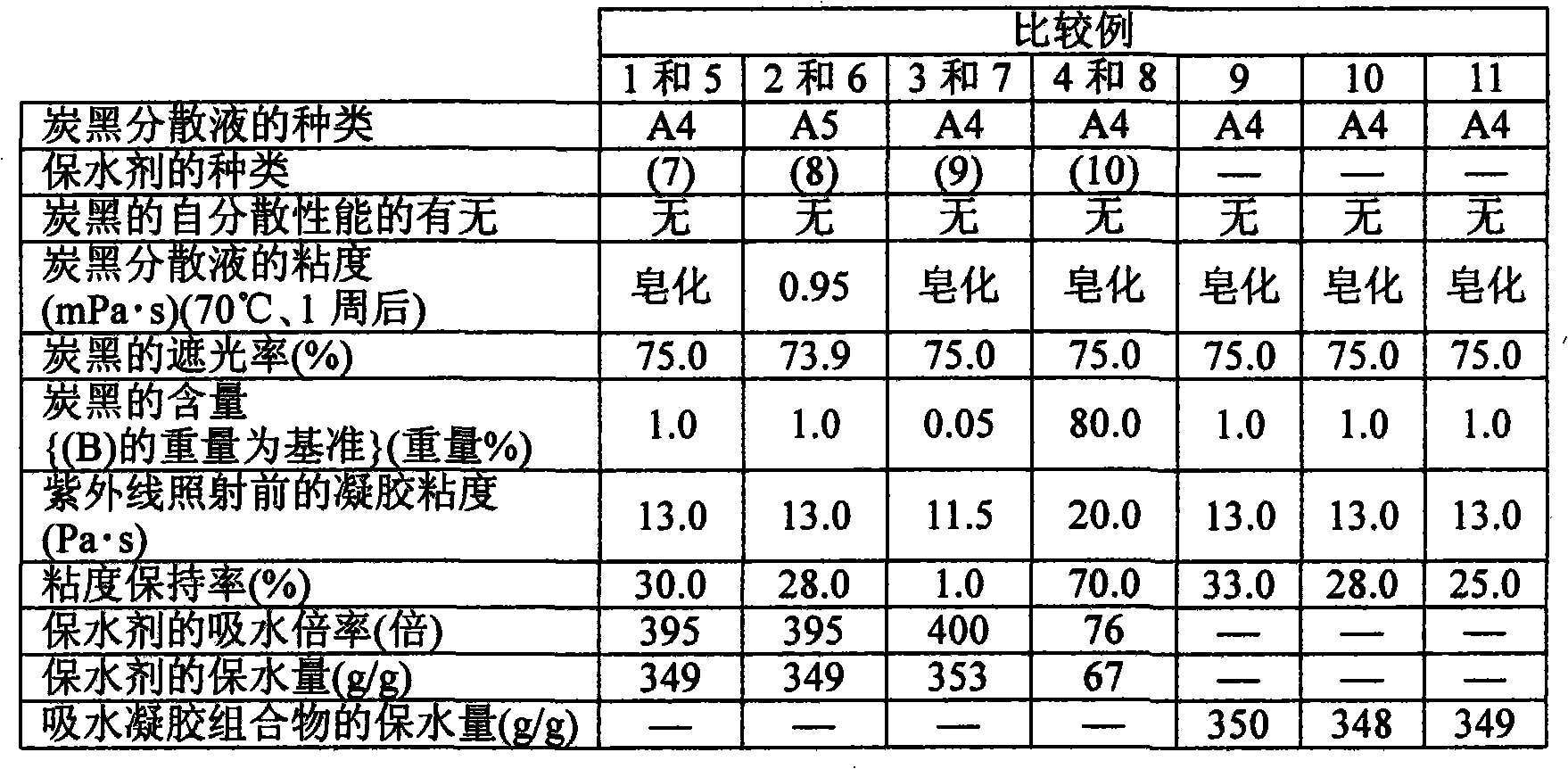

Examples

preparation example Construction

[0038] (Preparation of carbon black-containing water-absorbent resin)

[0039] While stirring 300 parts by weight of ion-exchanged water with a homomixer (2000 rpm), 0.1 part by weight of carbon black (A) having self-dispersibility in water was added to prepare a carbon black dispersion. Then, under agitation (2000 rpm) of the carbon black dispersion, 10 parts by weight of a water-absorbent resin (a water-absorbent resin composed of a cross-linked polymer of sodium acrylic acid salt and with a water absorption capacity of ion-exchanged water of 400 g / g) was added. (For example, Sunfresh (Sanfresh (registered trademark) GT-1) manufactured by Sanyo Chemical Industry Co., Ltd. (Sanyo Chemical Industry Co., Ltd.)) to prepare a water-absorbent gel composition. The obtained water-absorbent gel composition was placed in a circulating air dryer, and dried at 120° C. for 3 hours to obtain a carbon black-containing water-absorbent resin.

[0040] (Detection of shading rate)

[0041]In...

manufacture example 1

[0128] Cetyltrimethylammonium bromide adsorption specific surface area (CTAB) 140m 2 / g and carbon black (1) having a DBP (dibutyl phthalate) absorption value of 128 ml / 100 g was oxidized to obtain oxidized carbon black. The oxidation treatment is to add 100g carbon black to a concentration of 1.0mol / dm 3 Sodium peroxodisulfate aqueous solution 3dm 3 , at a reaction temperature of 60°C, a reaction time of 10 hours, and a stirring speed of 0.12s -1 under the conditions.

[0129] After the reaction is over, the oxidized carbon black is separated from the reaction solution by filtration, and the oxidized carbon black is mixed with a concentration of 1.0mol / dm 3 Aqueous sodium hydroxide solution for neutralization. After neutralization, use a centrifugal separator (manufactured by Hitachi Koki (Hitachi Koki), CR22F) at 7.5×10 -3 S -1 , 15 minutes under the conditions of classification. Then, after the supernatant was separated from the remaining salt with an ultrafiltration...

manufacture example 2

[0131] A carbon black dispersion (A2) having a dispersion concentration of 20% by weight was produced in the same manner as in Production Example 1 except that the classification treatment in Production Example 1 was not performed. The viscosity of the carbon black dispersion (A2) at 25° C. (after standing at 70° C. for one week) was 4.93 mPa·s, and the carbon black (a2) in (A2) already had self-dispersing properties. (a2) has a shading rate of 90.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com