Transformant transfected with flavin adenine dinucleotide-binding glucose dehydrogenase gene and method for producing flavin adenine dinucleotide-binding glucose dehydrogenase using the same

A technology of glucose dehydrogenase and flavin adenine, which is applied in biochemical equipment and methods, oxidoreductase, microbial measurement/inspection, etc. It can solve the problems of low glucose selectivity, difficult extraction and separation operations, and measurement of dissolved oxygen. The results have an impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

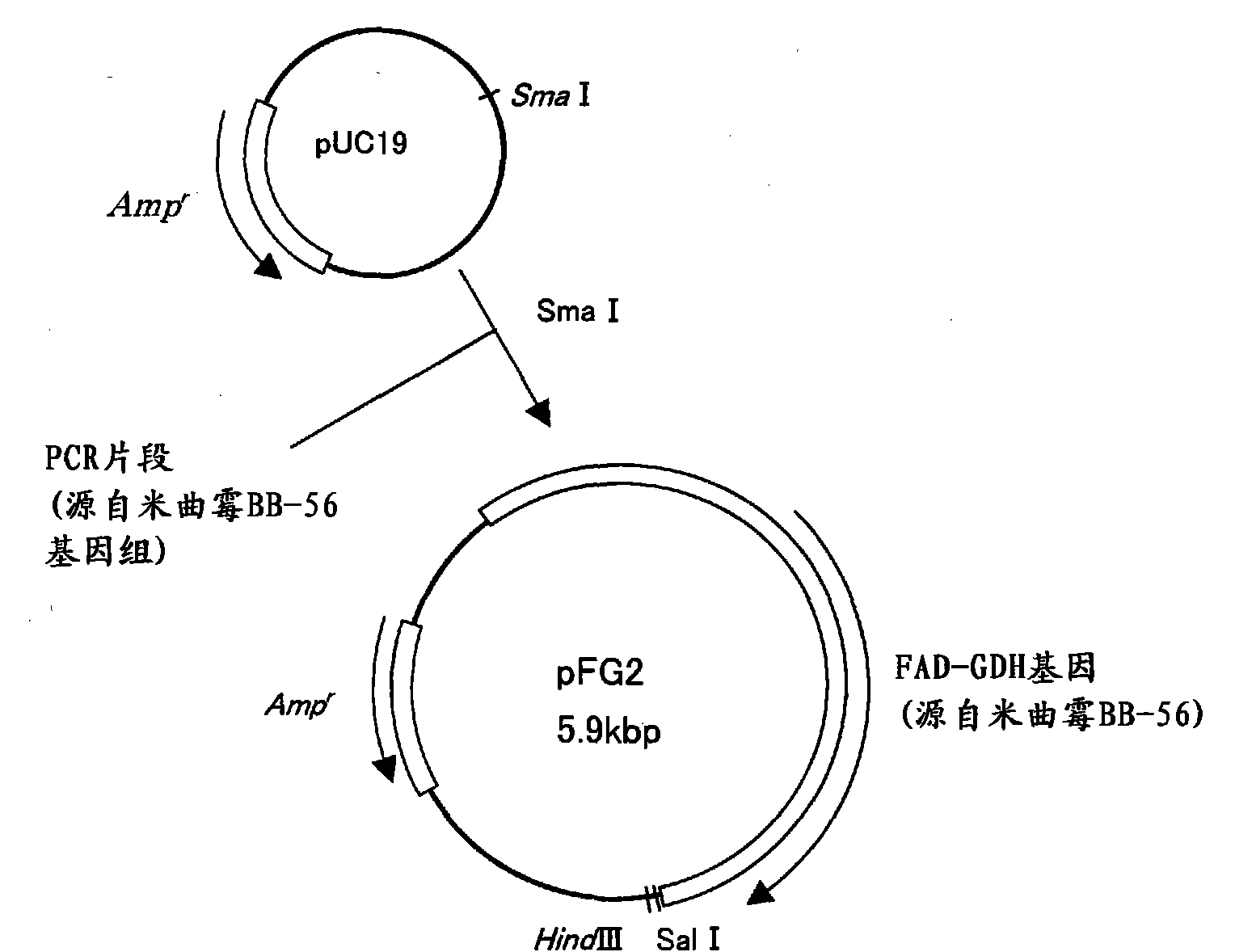

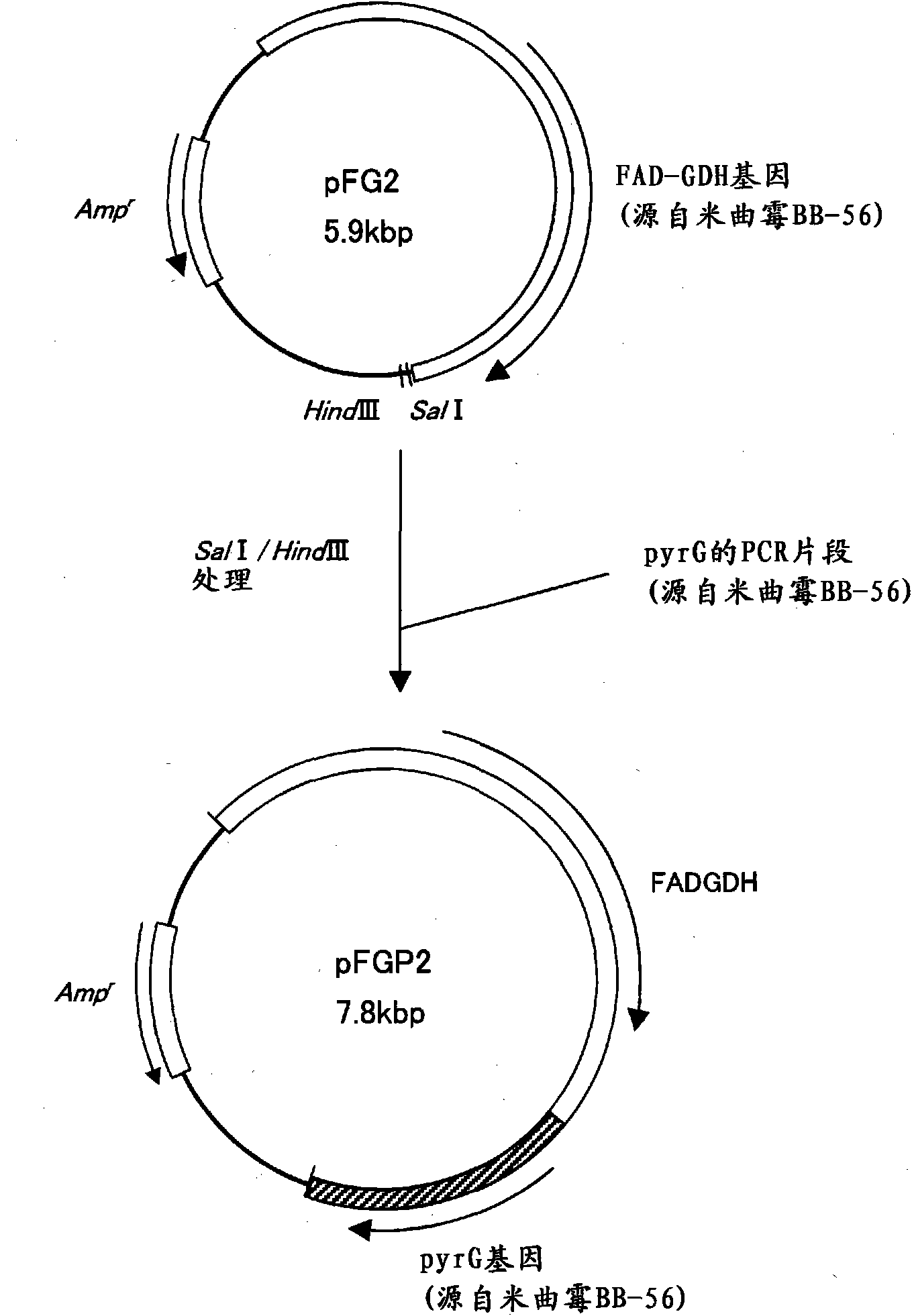

preparation example Construction

[0081] (Preparation method of FAD-GDH)

[0082] The second aspect of the present invention is to provide a method for producing FAD-GDH using the above transformant. In the production method of the present invention, first, the above-mentioned transformant is cultured under conditions that produce the protein encoded by the gene introduced therein (step (1)). The culture method and culture conditions are not particularly limited as long as the desired enzyme can be produced. That is, on the condition that the present enzyme is produced, the method and culture conditions for culturing the transformant to be used can be appropriately set. Hereinafter, as culture conditions, medium, culture temperature, and culture time are exemplified.

[0083] Any medium may be used as the medium in which the transformant to be used can grow. For example, carbon sources to which glucose, sucrose, gentiobiose, soluble starch, glycerin, dextrin, molasses, organic acids, etc. are added, as well...

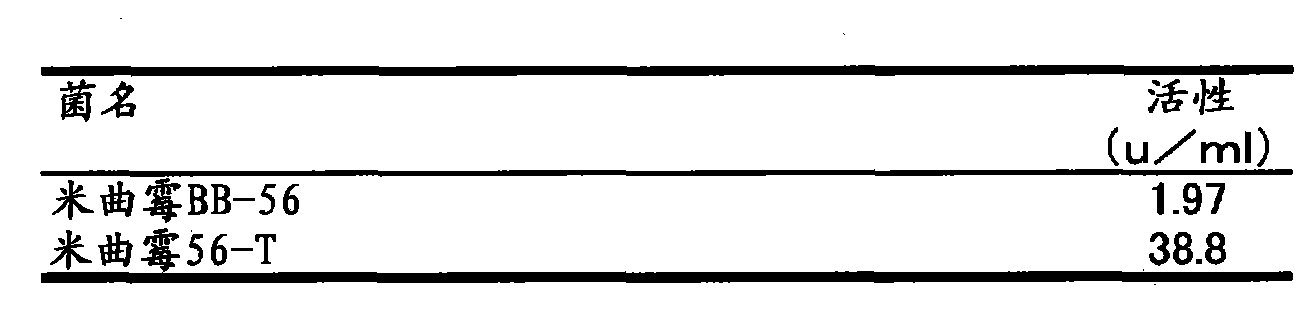

Embodiment 1

[0093]

[0094]According to the following procedure, Aspergillus oryzae BB-56 was cultured to produce FAD-GDH. 50 mL of a pre-cultured medium having the following composition was dispensed into a 300-mL Erlenmeyer flask, and sterilized at 121° C. and 0.12 MPa for 20 minutes. After cooling the medium to room temperature, Aspergillus oryzae BB-56 was inoculated, and cultured at 30° C. and 200 rpm for 3 days.

[0095] (Composition of pre-culture medium)

[0096] Yeast extract (Becton, Dickinson Company) 0.2% (w / v)

[0097] Soy peptone (DMV company) 1.0% (w / v)

[0098] Glucose (Wako Pure Chemical Industries, Ltd.) 2.0% (w / v)

[0099] K H 2 PO 4 (Wako Pure Chemical Industries, Ltd.) 0.1% (w / v)

[0100] MgSO 4 ·7H 2 O (Sigma-Aldrich Japan Co.) 0.05% (w / v)

[0101] Medium pH5.7

[0102] Production of FAD-GDH was carried out in a medium for main culture comprising the following composition. 50 mL of this main culture medium was divided into Erlenmeyer flasks with a volume...

Embodiment 2

[0112]

[0113] Purification of FAD-GDH was performed under the following conditions. The culture solution obtained as described above was filtered through celite to remove bacterial cells and other solid components in the culture solution. The clarified liquid obtained by this operation was desalted and concentrated with an ultrafiltration membrane. The concentrated solution is salted out with 90% saturated ammonium sulfate, and the centrifuged supernatant is desalted and concentrated with an ultrafiltration membrane. The desalted and concentrated solution was used in CM Sepharose Fast Flow (Amersham Biosciences) parallelized with 10 mM McIlvaine buffer pH 5.5 to adsorb FAD-GDH on the column. After the column was washed with 10 mM McIlvaine buffer pH 5.5, FAD-GDH was eluted with 10 mM McIlvaine buffer pH 5.5 containing 0.1 M NaCl, and the active fraction of FAD-GDH was recovered. The recovered active fraction was concentrated with an ultrafiltration membrane, and the conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com