Preparation method of magnetic chitosan compound microsphere immobilized marine alkaline proteinase

A technology of composite microspheres and chitosan, applied in the direction of being fixed on or in an inorganic carrier, immobilized on or in an organic carrier, etc., can solve the problems of application difficulty, not, and the difficulty of free enzyme to meet user requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

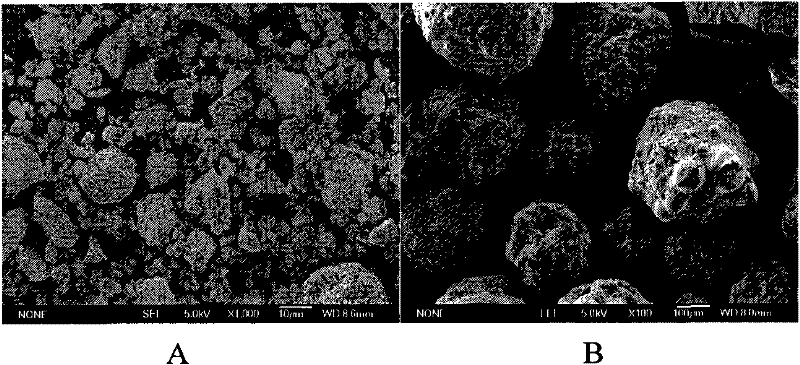

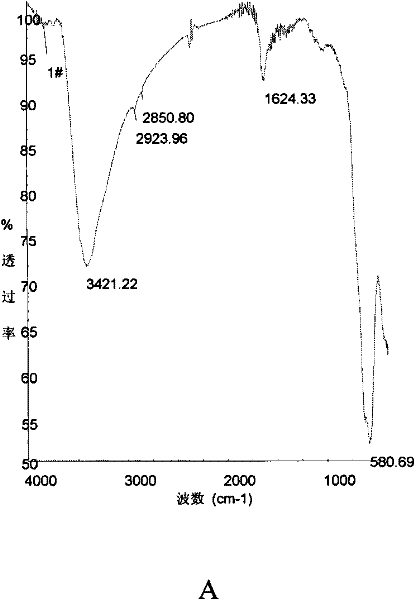

[0054] Put 30mL 0.5mol / L FeCl 2 Solution and 50mL 0.5mol / L FeCl 3 The solution is evenly mixed, and 8.0g PEG4000 is added. After it is fully dissolved, it is quickly added dropwise to 100mL of 5% diluted ammonia water under stirring, and the pH value of the solution is adjusted to 9.0 with ammonia water. After stirring for 30 minutes, ultrasonic for 10 minutes, 80°C water bath maturation for 30 minutes, and ultrasonic for 10 minutes to make the solution system uniform and fine. Finally, the supernatant liquid is poured under the adsorption of the magnet, washed with distilled water to neutrality, and freeze-dried in vacuum to obtain Fe 3 O 4 Magnetic core.

[0055] Accurately weigh 0.5g of chitosan, dissolve it in 20mL of 5wt% acetic acid solution to obtain 2.5wt% of chitosan acetic acid solution, add 0.5g Fe into the system 3 O 4 Magnetic core and mix well. Add dropwise to a mixed system consisting of 5mL of emulsifier Span-80 and 80mL of liquid paraffin with slow stirring. Afte...

example 2

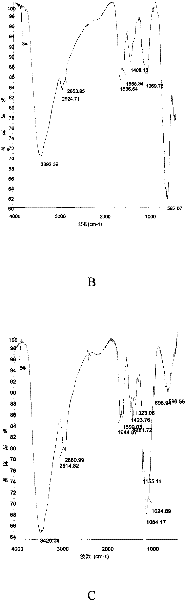

[0058] Put 25mL 0.6mol / L FeCl 2 Solution and 40mL 0.6mol / L FeCl 3 The solution is evenly mixed, and 6.0 g of PEG4000 is added. After it is fully dissolved, it is quickly added dropwise to 120 mL of 5 wt% dilute ammonia with stirring, and the pH of the solution is adjusted to 9.0 with ammonia. After stirring for 25 minutes, ultrasonic for 15 minutes, 70°C water bath maturation for 40 minutes, and ultrasonic for 20 minutes to make the solution system uniform and fine. Finally, the supernatant liquid is poured under the adsorption of the magnet, washed with distilled water to neutrality, and freeze-dried in vacuum to obtain Fe 3 O 4 Magnetic core.

[0059] Accurately weigh 0.5g of chitosan and dissolve it in 20mL of 5wt% acetic acid solution to obtain 2.5wt% of chitosan acetic acid solution. Add the above 0.25g Fe to this system 3 O 4 Magnetic core and mix well. Add dropwise to a mixed system consisting of 5mL of emulsifier Span-80 and 80mL of liquid paraffin under slow stirring. Af...

example 3

[0062] Put 40mL 0.4mol / L FeCl 2 Solution and 60mL 0.4mol / L FeCl 3 The solution is evenly mixed, 10.0g PEG4000 is added, and after it is fully dissolved, it is quickly added dropwise to 80mL of 5wt% dilute ammonia water under stirring, and the pH value of the solution is adjusted to 9.0 with ammonia water. After stirring for 40 minutes, ultrasonic for 10 minutes, aging in a water bath at 90°C for 20 minutes, and ultrasonic for 20 minutes to make the solution system uniform and fine. Finally, the supernatant liquid is poured under the adsorption of the magnet, washed with distilled water to neutrality, and freeze-dried in vacuum to obtain Fe 3 O 4 Magnetic core.

[0063] Accurately weigh 0.8g chitosan and dissolve it in 20mL 5wt% acetic acid solution to obtain 2.5wt% chitosan acetic acid solution. Add 0.5g Fe into the system 3 O 4 Magnetic core and mix well. Add dropwise to a mixed system consisting of 5mL of emulsifier Span-80 and 80mL of liquid paraffin with slow stirring. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com