A regeneration method for a deactivated selective catalytic reduction denitrification catalyst

A denitrification catalyst and selective technology, which is applied in the field of regeneration of deactivated selective catalytic reduction denitrification catalyst, can solve the problems of poor activity recovery ability of deactivated catalyst and decline of catalyst mechanical strength, and achieve the degree of activity recovery and avoid corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Regeneration treatment of deactivated SCR denitration catalyst

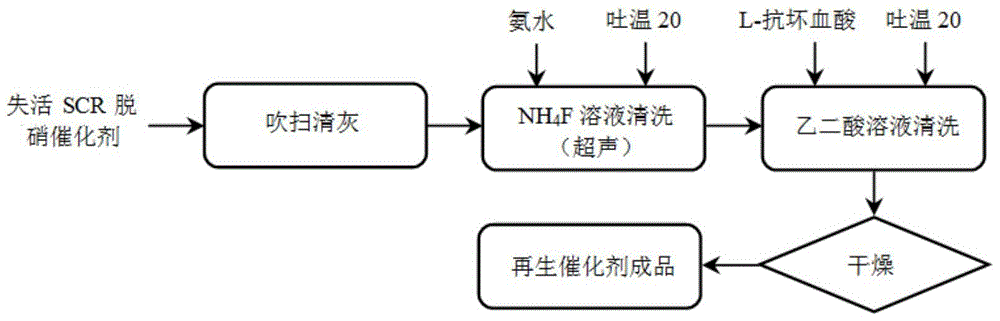

[0038] A regeneration method of a deactivated selective catalytic reduction denitrification catalyst in this embodiment, its technological process is as follows figure 1 Shown, the concrete steps of this regeneration method are:

[0039] (1) Take a deactivated SCR denitrification catalyst (V 2 o 5 -WO 3 / TiO 2 , wall thickness: 1.1mm, pitch: 8.2mm, catalyst size: 150mm×150mm×800mm), use clean and dry compressed air to blow the deactivated SCR denitrification catalyst to remove the fly ash deposited on the surface of the catalyst, for the subsequent catalyst Prepare for the regeneration process; among them, the working pressure of compressed air is 0.5MPa, and the gas flow rate is 0.5m 3 / s, the purge time is 10min.

[0040] (2) Place the catalyst after soot blowing treatment in 100L of the first cleaning solution, and perform ultrasonic-assisted cleaning at room temperature 25°C for 20min to remov...

Embodiment 2

[0058] 1. Regeneration treatment of deactivated SCR denitration catalyst

[0059] A regeneration method of a deactivated selective catalytic reduction denitrification catalyst in this embodiment, its technological process is as follows figure 1Shown, the concrete steps of this regeneration method are:

[0060] (1) Take a deactivated SCR denitrification catalyst (V 2 o 5 -WO 3 / TiO 2 , wall thickness: 1.1mm, pitch: 8.2mm, catalyst size: 150mm×150mm×800mm), use clean and dry compressed air to blow the deactivated SCR denitrification catalyst to remove the fly ash deposited on the surface of the catalyst; among them, the compressed air The working pressure is 0.8MPa, the gas flow rate is 1.0m 3 / s, the purge time is 18min.

[0061] (2) Place the catalyst after soot blowing treatment in 100L of the first cleaning solution, and perform ultrasonic-assisted cleaning at room temperature 23°C for 80min to remove SiO deposited on the surface of the catalyst 2 , the first cleaning...

Embodiment 3

[0069] 1. Regeneration treatment of deactivated SCR denitration catalyst

[0070] A regeneration method of a deactivated selective catalytic reduction denitrification catalyst in this embodiment, its technological process is as follows figure 1 Shown, the concrete steps of this regeneration method are:

[0071] (1) Take a deactivated SCR denitrification catalyst (V 2 o 5 -WO 3 / TiO 2 , wall thickness: 1.1mm, pitch: 8.2mm, catalyst size: 150mm×150mm×800mm), use clean and dry compressed air to blow the deactivated SCR denitrification catalyst to remove the fly ash deposited on the surface of the catalyst; among them, the compressed air The working pressure is 1.5MPa, the gas flow rate is 1.2m 3 / s, the purge time is 20min.

[0072] (2) Place the catalyst after soot blowing treatment in 100L of the first cleaning solution, and perform ultrasonic-assisted cleaning at room temperature 27°C for 20 minutes to remove SiO deposited on the surface of the catalyst 2 , the first cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com