Method for preparing magnesium-based desulfurizing agent

The technology of magnesium-based desulfurizer and modifier is applied in the field of additives for desulfurizers in iron and steel smelting, which can solve the problems of high speed, affecting fluidity, and increasing flame retardant time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

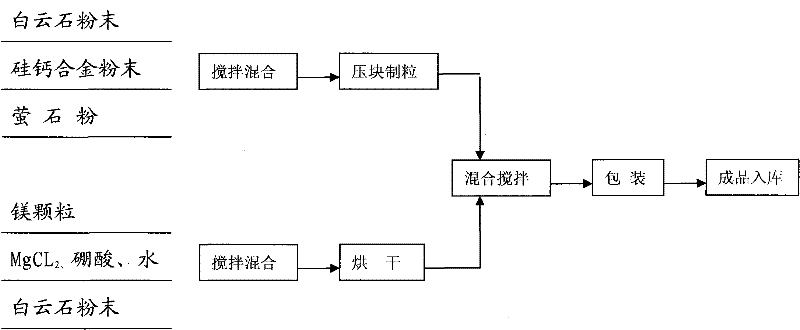

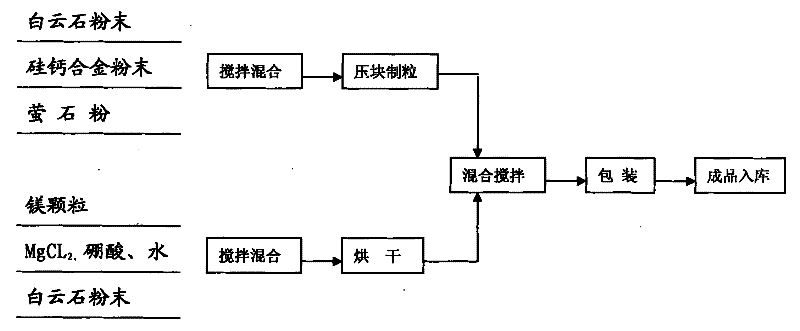

[0015] like figure 1 The preparation method of the magnesium-based desulfurizer shown is prepared according to the following steps.

[0016] 1. Preparation of improver: Stir and mix calcined dolomite powder, silicon-calcium alloy powder, and fluorite powder in a mass ratio of 6:1:3. After mixing, the dry powder is briquetted and granulated, with a particle size of 1.0-1.6mm;

[0017] 2. Preparation of coated granule magnesium: crystalline magnesium chloride, boric acid, and water are prepared into a solution at a mass ratio of 1:0.1:100, and this solution accounting for 8% of the proportion of magnesium granules is added to the magnesium granules and stirred, and added 2% of the proportion of magnesium granules. % calcined dolomite powder, stirred at a low speed and heated and dried so that the water content does not exceed 0.5%, it is mainly used to increase the burning resistance time of the desulfurizer.

[0018] 3. Add the modifier accounting for 5-7% of the mass of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com