Method for preparing dye sensitization solar battery electrode at low temperature

A solar cell and dye sensitization technology, which is applied in the field of low-temperature preparation of dye-sensitized solar cell electrodes, can solve the problems of high energy consumption and high risk, reduce transmission resistance, increase photocurrent, and avoid long-term high-temperature hydrothermal reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of slurry

[0026] The molar ratio of titanium isopropoxide: ethylene glycol: glacial acetic acid is 1:3:20. Put ethylene glycol in a round-necked flask, heat evenly to 60°C, and add titanium isopropoxide dropwise under vigorous stirring. After the dropwise addition, keep stirring at this temperature for 15 minutes, then add glacial acetic acid, gradually raise the temperature to 90°C, and stir for 12 hours. At this time, the sol solution is transparent.

[0027] The sol solution obtained above was mixed with P25 titanium dioxide particles at a mass ratio of 1:1, and ground by a high-energy ball mill for 4 hours to prepare a titanium dioxide slurry.

[0028] (2) Preparation of thin film

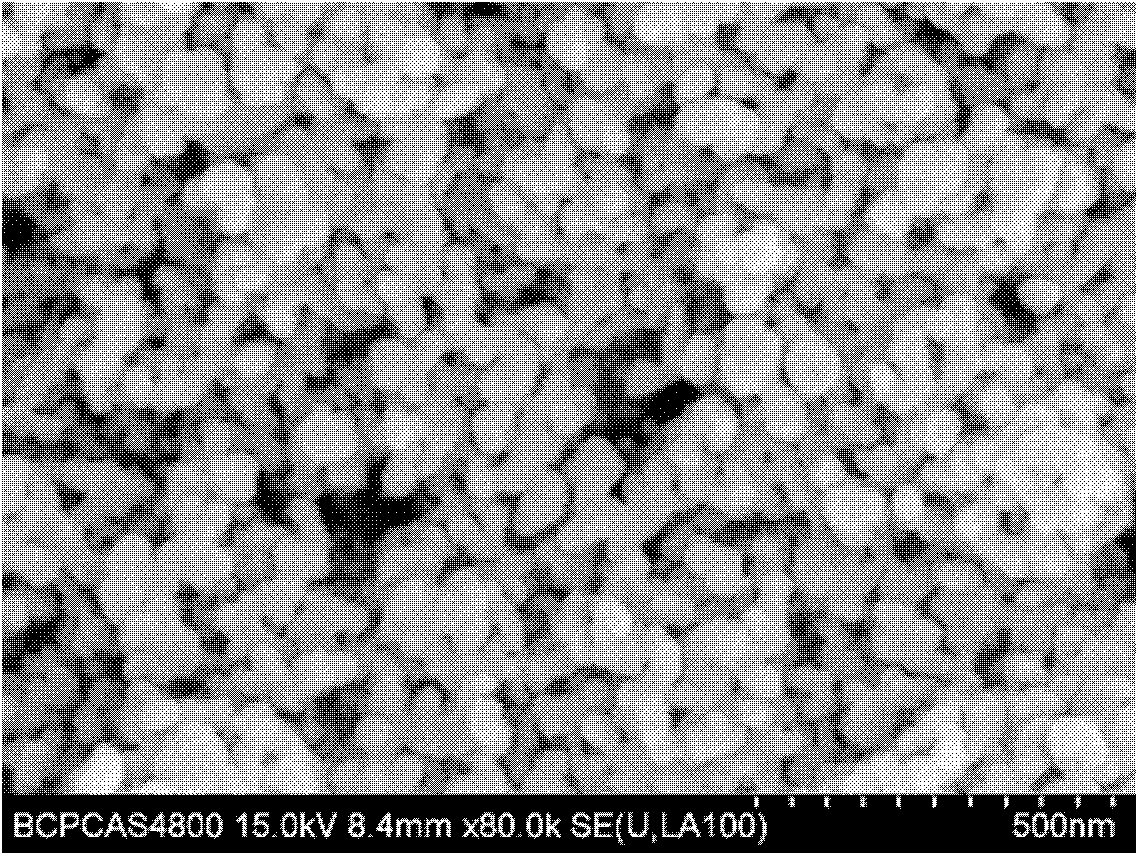

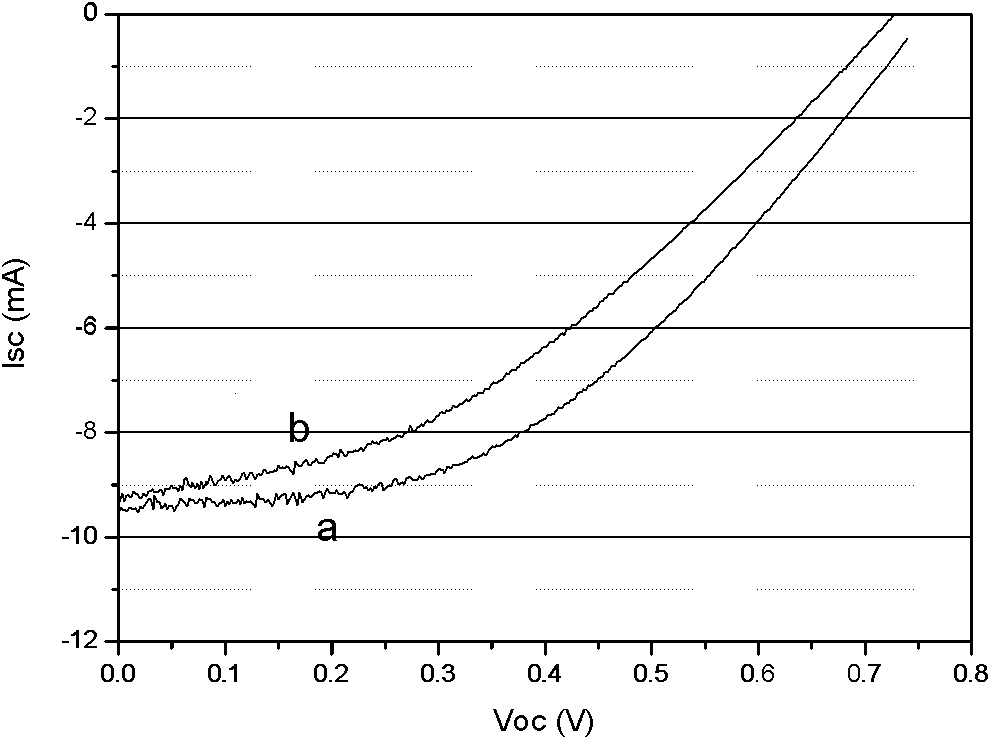

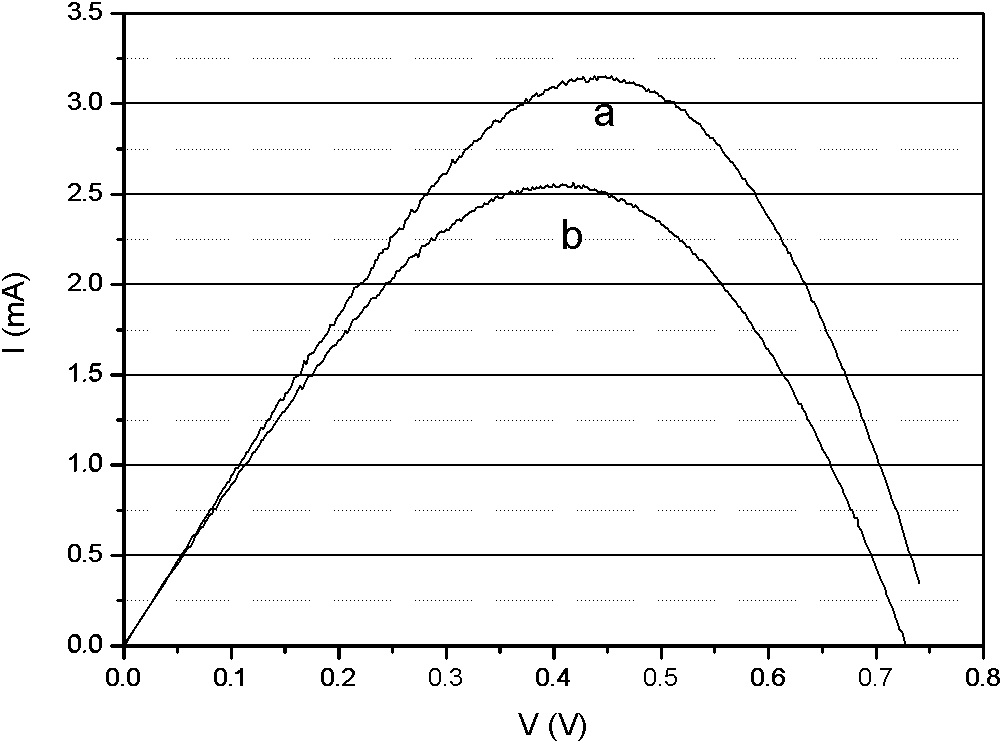

[0029] Take an appropriate amount of the above slurry and apply it to form a film. The working area of the film is 1cm 2 , the thickness is 8-10μm. After natural drying, put it into a muffle furnace, raise the temperature to 200°C for 15 minutes, 250°C for 15 minut...

Embodiment 2

[0033] Embodiment two and embodiment one step are the same, difference is: when preparing sol solution, titanium isopropoxide: ethylene glycol: glacial acetic acid molar ratio 1: 10: 20; When mixing with P25 type titanium dioxide particles to prepare slurry, The mass ratio of sol solution to P25 titanium dioxide is 3:1.

Embodiment 3

[0035] The steps of embodiment three are the same as those of embodiment one, except that: when preparing the sol solution, titanium isopropoxide: ethylene glycol: glacial acetic acid in a molar ratio of 1:20:20; when mixing with P25 type titanium dioxide particles to prepare slurry, The mass ratio of sol solution to P25 type titanium dioxide is 10:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com