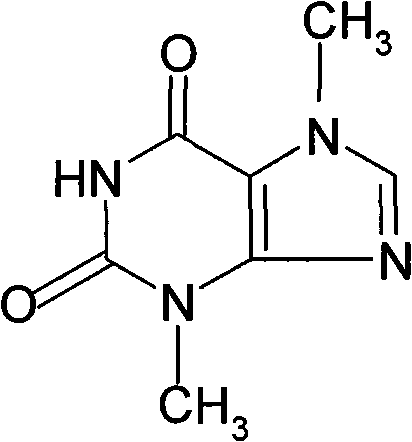

Theobromine production process

A technology of theobromine and solvent, applied in the field of preparation and refining of theobromine, can solve the problems of flammability, difficulty in removal, toxicity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

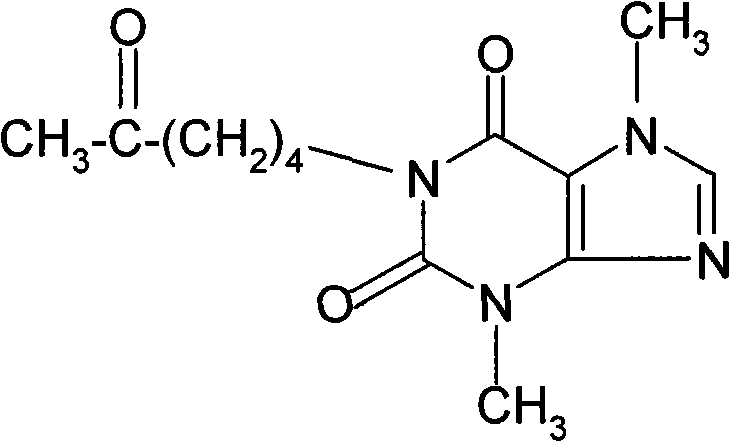

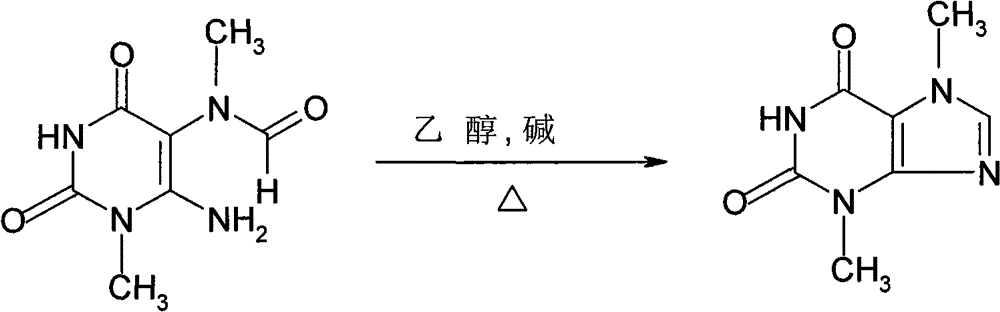

Method used

Image

Examples

example 2

[0086] This example demonstrates the preparation of theobromine in a mixture of acetone and water in the presence of sodium bicarbonate.

[0087] 16.6 g of 3-methylxanthine (0.1 mol) and 100 ml of acetone were mixed in a 500 ml four-necked reaction vessel equipped with a mechanical stirrer, and 20 ml of water were added. 36 g of sodium bicarbonate were added with stirring and heated to a temperature of 55-60°C. 20 g of dimethyl sulfate were added dropwise over 3.5 hours and kept stirring at 55-60° C. for half an hour. Then, acetone is distilled off and recovered. 50 ml of water were added and the reaction vessel was heated to 80°C. Then, 32% hydrochloric acid was slowly added to the mixture, and the measured pH was in the range of 5-6. The mixture was cooled to 25°C, whereby the solid formed was obtained by precipitation, washed with water and dried at 70°C; 15.7 g of theobromine were obtained in 87% yield with a purity of 99.9% by HPLC.

example 3

[0089] This example demonstrates the preparation of theobromine in the presence of sodium carbonate in acetone.

[0090] In a 500ml four-necked reaction vessel equipped with a stirrer, 3-methylxanthine disodium salt (63g), acetone (304ml) and sodium carbonate (19.1g) were added with continuous stirring. The mixture was slowly heated to about 55°C. Dimethyl sulfate (60 g) was added dropwise over 4 hours. Then, the reaction was kept at 55°C for half an hour. Acetone was distilled off at normal pressure and water (50ml) was added. The product solution was neutralized to a pH of around 5 using 32% hydrochloric acid at 30°C. Then, the solution was filtered, washed with warm water (15 ml) at 40°C, filtered under reduced pressure to remove water, and dried at 70°C to obtain crude theobromine in 86.7% yield.

example 4

[0092] This example demonstrates the preparation of theobromine in acetone in the presence of sodium carbonate.

[0093] In a 500ml four-necked reaction vessel equipped with a stirrer, 3-methylxanthine disodium salt (63g), acetone (304ml) and sodium carbonate (19.1g) were added under stirring. The mixture was heated to 55°C and dimethyl sulfate (60 g) was added dropwise over 3.5 hours. Then, the reaction was maintained at 55°C for another half hour. Acetone was evaporated at atmospheric pressure. Water (50ml) was added. The resulting product solution was neutralized to a pH of around 6 using 32% industrial hydrochloric acid at 30°C. Then, the solution was filtered, washed with warm water (10 ml) at 40°C, filtered under reduced pressure to remove water, and dried at 70°C to obtain theobromine in 84.3% yield.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com