Method for making carbon nano tube/polystyrene composite conductive material

A technology of carbon nanotubes and polystyrene, which is applied in the field of semiconductor technology, can solve problems such as mechanical properties, optical transparency comprehensive performance, destruction of polymer material structure and properties, polymer chain damage, etc., to improve purity, The effect of reducing production costs and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

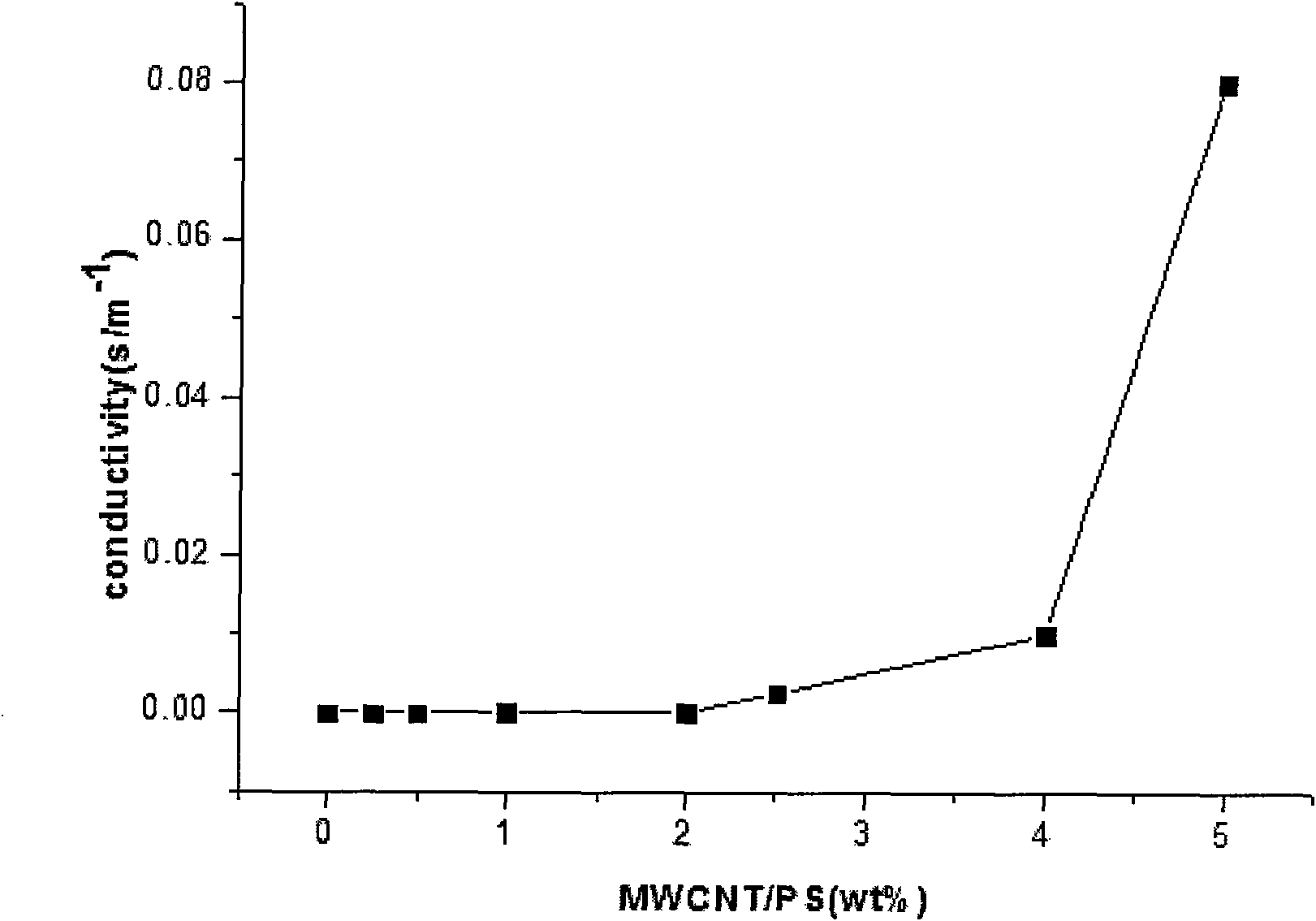

[0029] The invention provides a preparation method of a polystyrene composite conductive material containing carbon nanotubes. The method comprises the following steps: configure a polystyrene solution with a lower concentration with a specific solvent, and disperse the carbon nanotubes by wrapping the carbon nanotubes with polystyrene (without adding any carbon nanotube dispersant); For the required ratio, use the same solvent to configure a polystyrene solution with a higher concentration; mix the two dispersions evenly; add the mixture to another solvent, and the carbon nanotubes and the carbon nanotubes wound on the carbon nanotubes Polystyrene precipitated simultaneously; the resulting solid composite sample was collected by filtration.

[0030] Wherein: the solute concentration of the low-concentration polystyrene solution configured in the first step is between 0.1 to 4 wt%, and the concentration of the dispersed carbon nanotubes is 0.1 to 3 wt%; the polystyrene solutio...

Embodiment 1

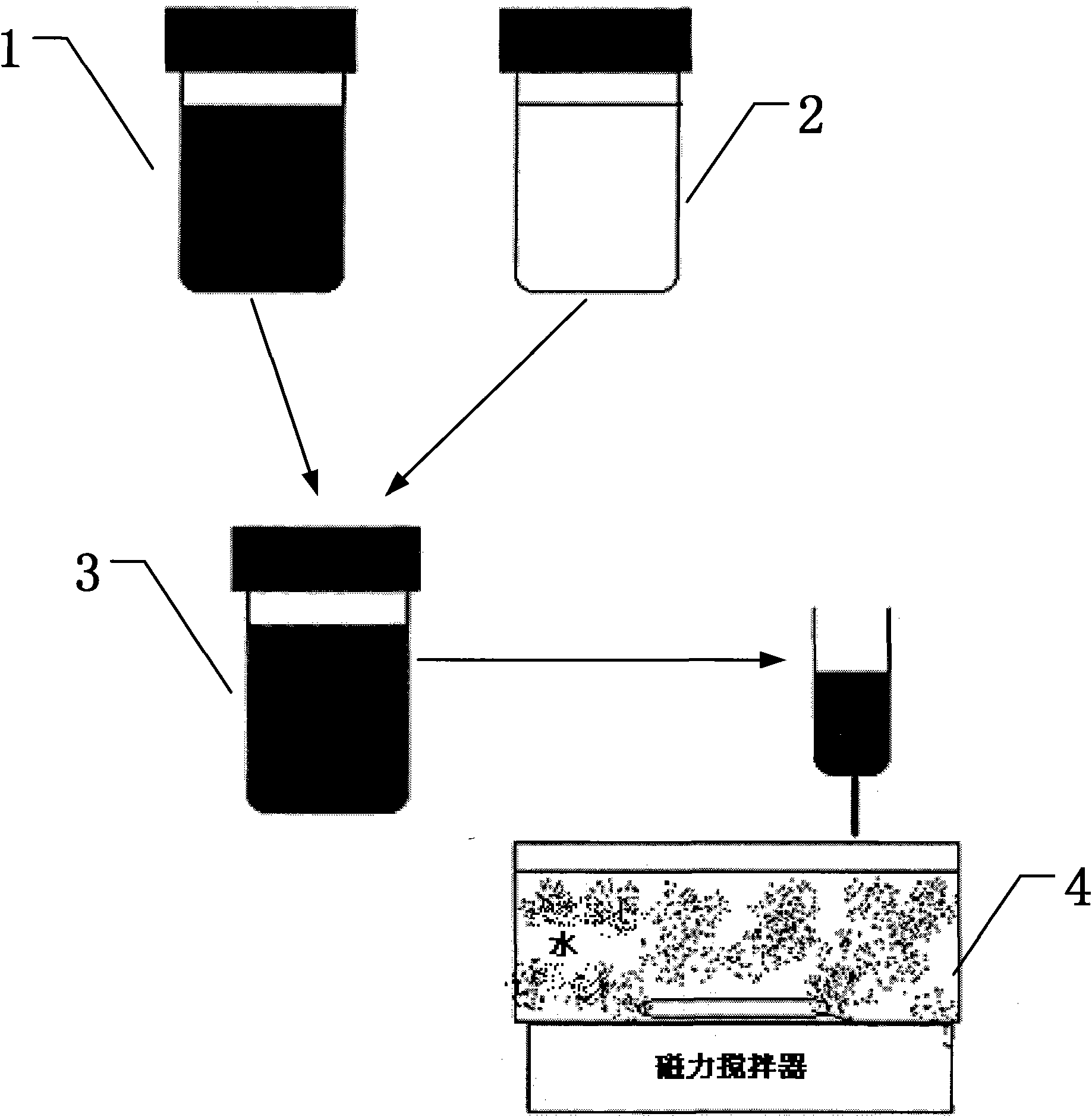

[0034] Such as figure 1 Shown is a schematic flow chart of the preparation method of the carbon nanotube / polystyrene composite conductive material of the present invention, comprising the following steps:

[0035] In step 1, a matrix material polystyrene is used as a dispersant to provide a uniform and stable dispersion of carbon nanotubes. Firstly, polystyrene is fully dissolved in DMF (N, N-dimethylformamide) solvent, and the proportioning concentration is 2%. Then add 0.2% carbon nanotube powder therein, and 100W ultrasonic treatment for 4 hours, and then a uniformly dispersed carbon nanotube dispersion 1 can be obtained.

[0036] Step 2, fully dissolving solid polystyrene in DMF solvent to obtain polystyrene solution 2 with a proportioning concentration of 5%.

[0037] In step 3, according to the content of carbon nanotubes in the required composite material, appropriate amounts of the two dispersions in step 1 and step 2 are respectively taken and mixed. Under the acti...

Embodiment 2

[0041] Fully dissolve polystyrene block copolymer ABS in DMF (N, N-dimethylformamide) solvent, the proportioning concentration is 2%, then add 0.2% carbon nanotube powder therein, 100W ultrasonic treatment After 4 hours, a uniformly dispersed carbon nanotube dispersion A was obtained. Add ABS to another part of DMF solvent, stir to make it fully dissolved, and the proportioning concentration is 5%, to obtain solution B. After mixing liquid A and liquid B, continue to stir for half an hour, pour the mixed liquid into deionized water stirred at high speed, let it stand for a period of time, and then filter and dry to obtain the required composite conductive sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com