Paint for train body surface of high speed train

A technology for surface coatings and high-speed trains, applied in the direction of coatings, etc., can solve problems such as inadequacies, and achieve the effects of prolonging the construction period, excellent weather resistance, and accelerating the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] A coating for the surface of a high-speed train car body, the composition of each component in the formula is as follows,

[0056] Among them, group A is:

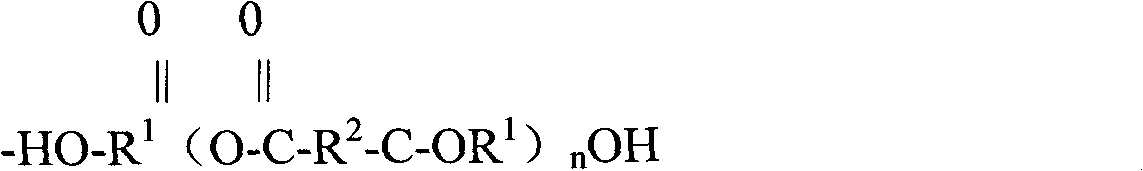

[0057] Elastic polyester 30%,

[0058] Acrylic 12%,

[0059] Polymer hyperdispersant 0.8%,

[0060] Defoamer 0.394%,

[0061] Leveling agent 0.4%,

[0062] Anti-sagging agent 3%,

[0063] UV absorber 0.4%,

[0064] Rutile titanium dioxide 24%,

[0065] Ultrafine Cenospheres 8%,

[0066] Nano ATO 4%,

[0067] nano-SiO 2 4%,

[0068] Mixed solvent 13%,

[0069] Catalyst 0.006%;

[0070] Component B is: HDI trimer N-3390, the ratio of components A and B is listed as 100:30;

[0071] The proportions of the above components and ingredients are all calculated by weight percentage.

[0072] Its preparation process steps are as follows:

[0073] Preparation of Component A

[0074] a. Nano-ATO and nano-SiO 2 Pretreatment: matrix resin + polymer hyperdispersant + nano-ATO and nano-SiO 2 , mixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com