Exhaust gas analyzer and probe unit

A detection unit and analysis device technology, which is applied in the field of detection units, can solve problems such as inability to supply calibration gas, complicated sensor bracket structure, and increased consumption of calibration gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

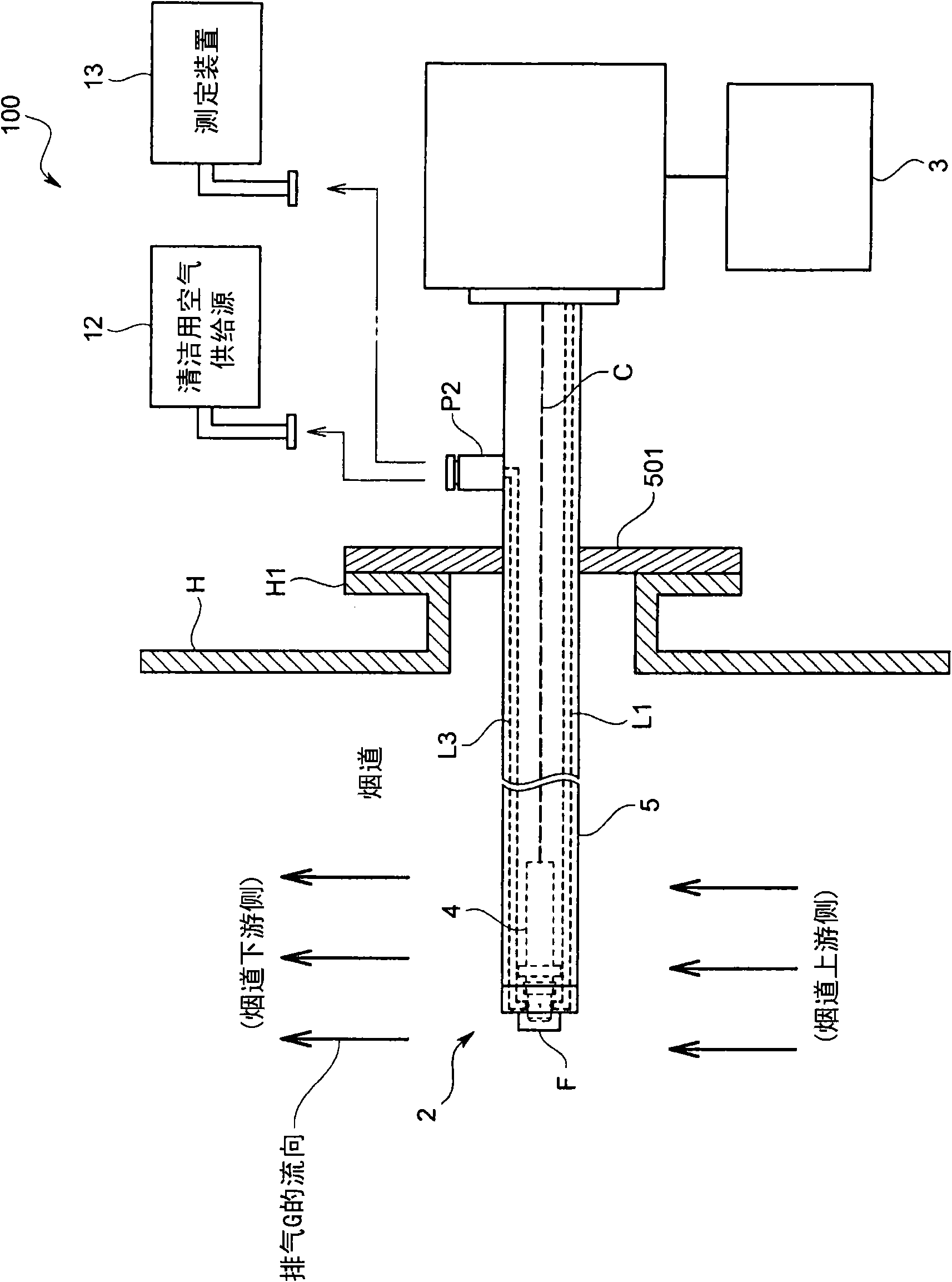

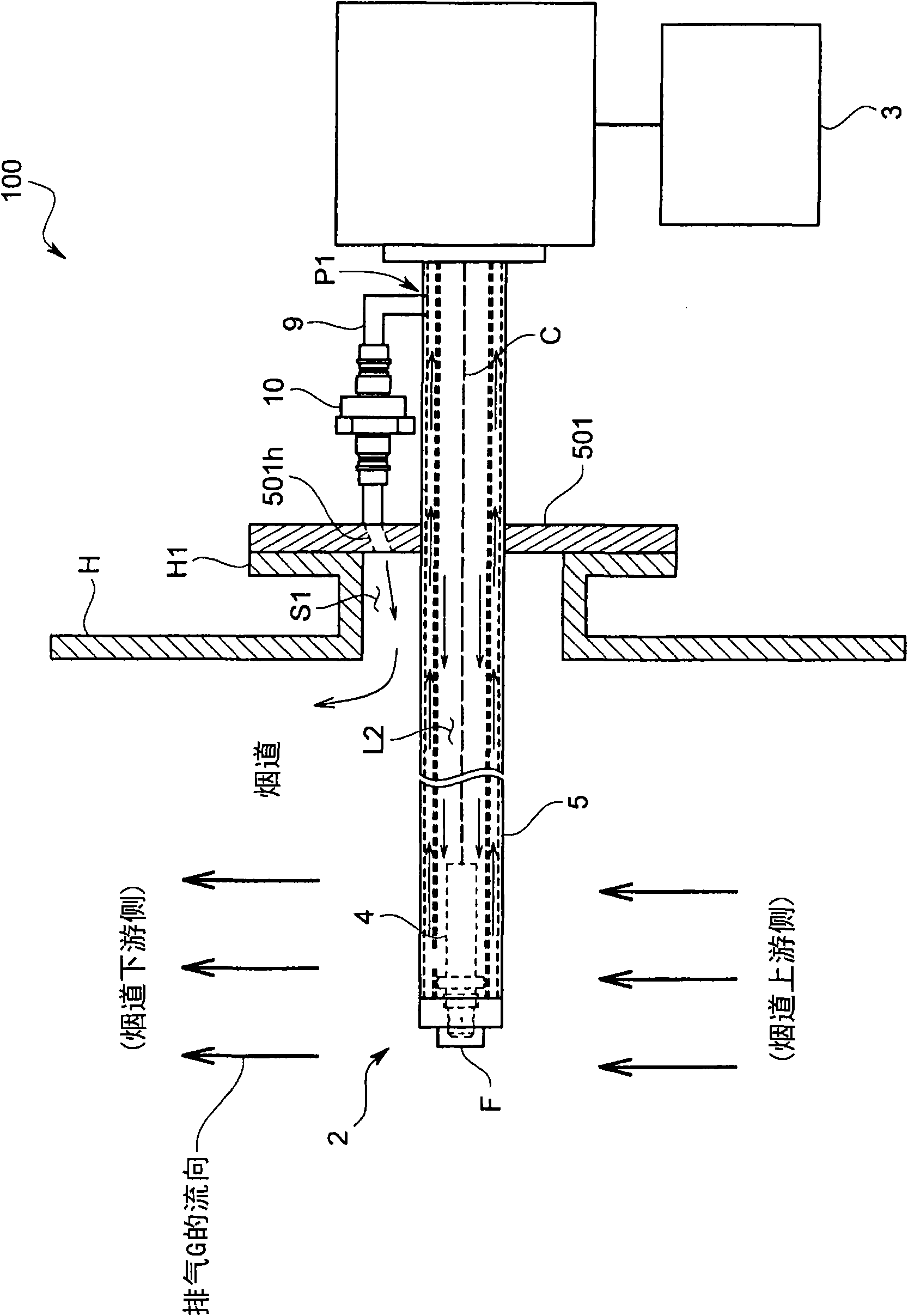

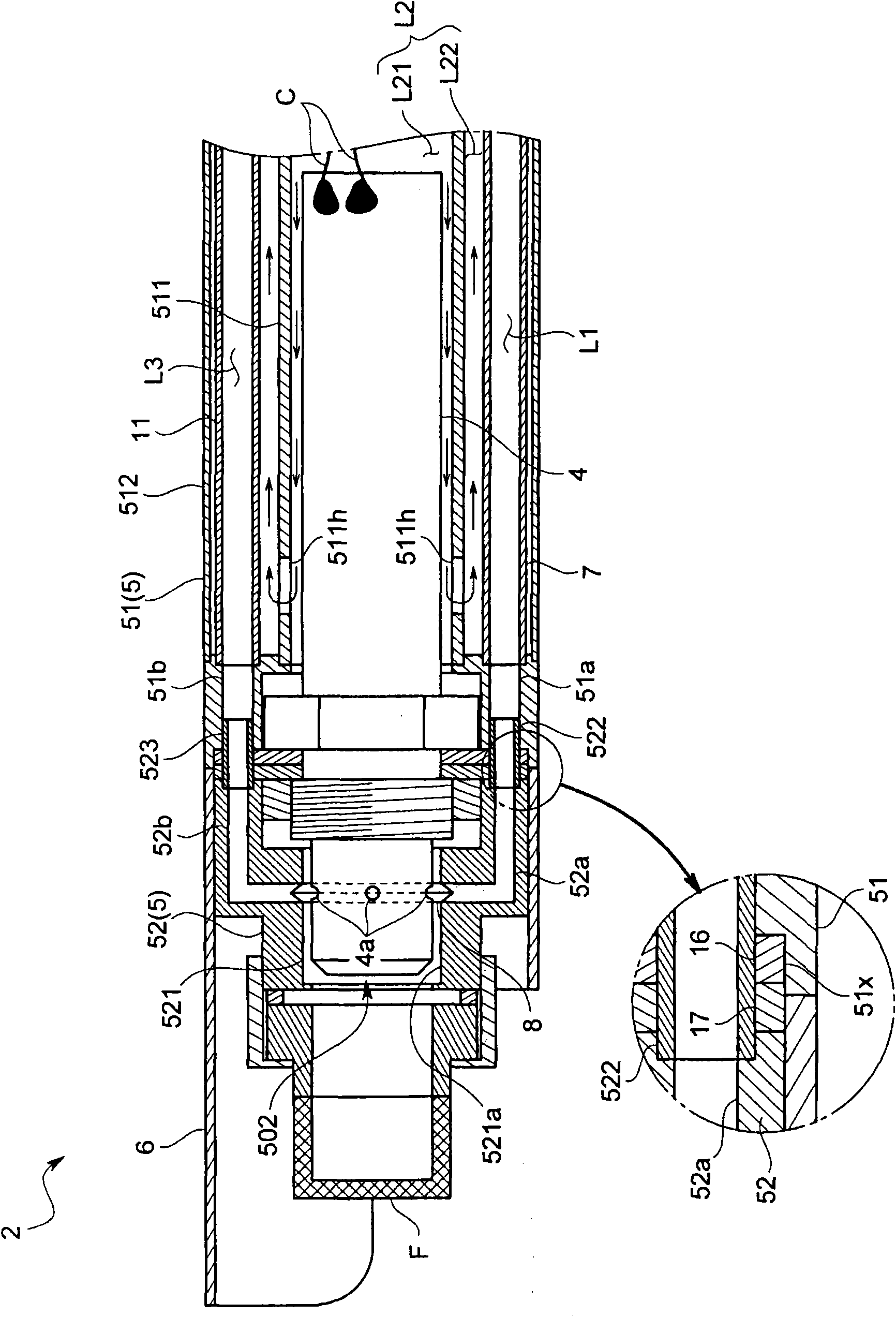

[0039] Next, an embodiment of an exhaust gas analysis device according to the present invention will be described with reference to the drawings.

[0040]

[0041] The exhaust gas analysis device 100 according to the present embodiment is for the exhaust gas G flowing through the flue in the exhaust pipe H connected to a boiler such as a lime incinerator or a heavy oil incinerator, or an internal combustion engine such as a steam engine or a ship engine. The specified components contained (such as NOx, SOx, CO 2 , CO, etc.) is a direct insertion type exhaust gas analyzer for analysis. In addition, the analysis results obtained by using the exhaust gas analysis device 100 (such as the concentration of specified components) can be used for control of denitrification or desulfurization, and the like.

[0042] Such as figure 1 and figure 2 As shown, this device specifically includes: a detection unit 2, which is fixed on the exhaust pipe H, so that its top end is protruded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com