Fermented preparation method of vegetables

A vegetable and pre-fermentation technology, applied in the fields of vegetable fermentation processing and vegetable deep processing, can solve problems such as unfavorable factoryization, large-scale and standardized production, difficulty in realizing large-scale industrial production, and difficulty in ensuring product consistency, saving personnel. and equipment investment, easy to store and eat, good flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

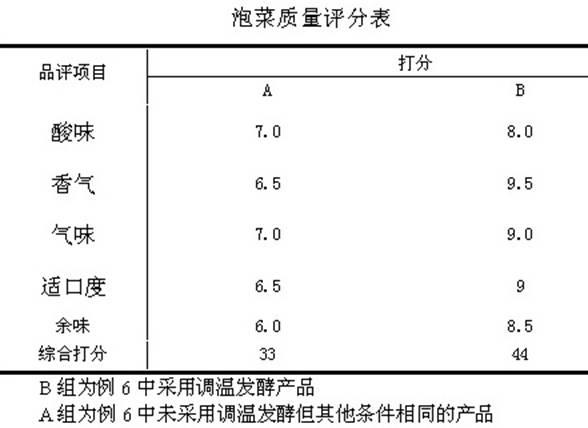

Examples

Embodiment 1

[0025] 100 kg of bitter vegetables are selected, washed, cut into strips, and put into kimchi altar containers. Add 1 kg of salt, 1.5 kg of sucrose, 1 kg of pepper, 0.1 kg of star anise, 0.1 kg of kaempferen, 0.1 kg of weed, 500 g to plantarum powder, the container is then sealed. Control the temperature at 30°C for 10 hours of pre-fermentation, control the temperature at 25°C for 50 hours of post-fermentation, and lower the temperature to 0-2°C for 5 hours in the middle; use dehydration equipment to remove water after fermentation, and the added content is 0.5 kg Garlic, 0.1 kg of chili powder, 0.2 kg of fresh ginger, and 0.05 kg of monosodium glutamate are crushed and mixed, and the bitter bitter vegetable is mixed with the above-mentioned seasoning mixture and then packaged and sterilized to obtain the bitter bitter vegetable kimchi product.

Embodiment 2

[0027] 100 kg of bitter vegetables are selected and washed, cut into strips and put into stainless steel containers. Add 2 kg of salt, 1 kg of sucrose, 0.5 kg of pepper, 0.2 kg of star anise, 0.2 kg of kaempferen, 0.5 kg of weed, and 30 grams of vegetable milk Bacteria powder, then seal the container. Control the temperature at 30°C for 10 hours of pre-fermentation, control the temperature at 15°C for 90 hours of post-fermentation, reduce the temperature to 0-3°C for 4 hours at 20 hours and 50 hours of post-fermentation, and then return to normal; Remove water, add 0.5 kg of garlic, 0.1 kg of chili powder, 0.2 kg of fresh ginger, and 0.08 kg of monosodium glutamate, mix bitter bitter herbs with the above-mentioned seasoning mixture, and vacuum pack bitter bitter herbs .

Embodiment 3

[0029] 100 kg of bitter vegetables are selected and washed, cut into strips and put into containers. Add 1.5 kg of salt, 2 kg of sucrose, 0.6 kg of Chinese pepper, 1.0 kg of star anise, 0.2 kg of kaempferen, 0.3 kg of weed, and 10 g of Bulgarian fungus powder , and then seal the container. Control the temperature at 30°C for 10 hours of pre-fermentation, control the temperature at 30°C for 30 hours of post-fermentation, and after 10 hours of post-fermentation, lower the temperature to 0-2°C for 4 hours; add 2.0 kg of garlic and 0.2 kg of garlic after fermentation The pulverized mixture of chili powder, 0.2 kg of fresh ginger, and 0.08 kg of monosodium glutamate, kimchi and the above-mentioned seasoning mixture are mixed, and the bitter bitter vegetable product is obtained through vacuum packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com