Light variation anti-forgery element with multiple anti-forgery functions

A technology of anti-counterfeiting components and functions, applied in optics, nonlinear optics, printing, etc., can solve problems such as increasing the technical difficulty of counterfeiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] On the surface of the PET substrate (substrate layer) 1, metal ink is used to print the negative pattern in the form of gravure to form the negative text "PEOPLE", and dry to form a partial metal layer (hollow metal layer) 2;

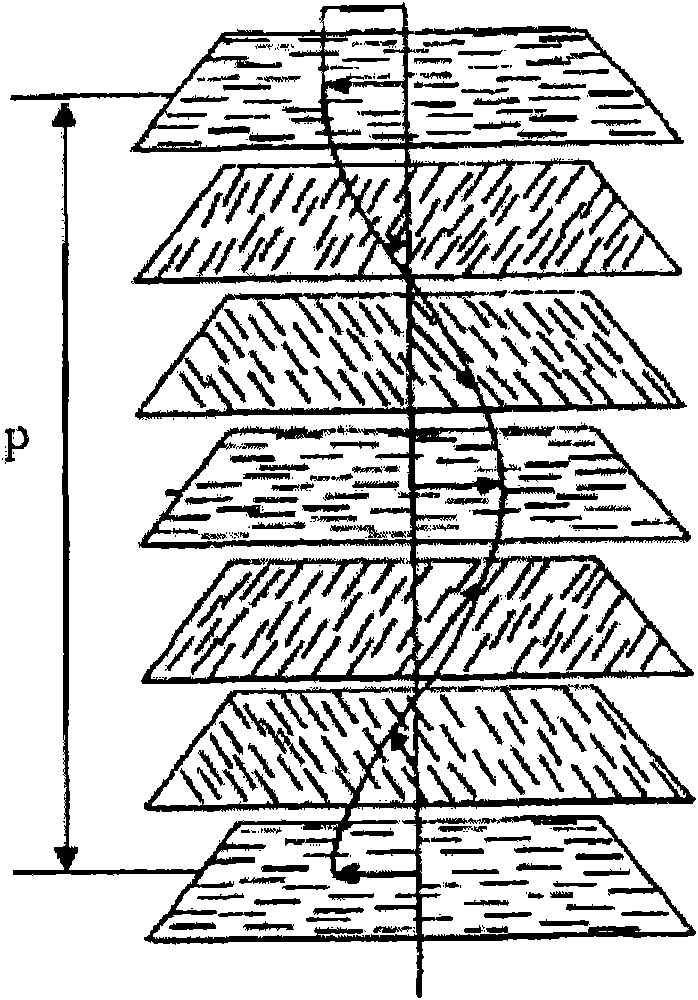

[0057] Apply a solution of LPP (molecular formula III) with a concentration of 2% on the other side of the substrate, dry it, and control the thickness to about 50nm to form a linear photopolymerization material layer; "The photomask plate uses a certain angle of linearly polarized ultraviolet light to ray the linear photopolymerization material layer, so that the photo-alignment material molecules irradiated by the light will be arranged into patterns and solidified; then remove the photomask plate and use another angle The rest of the linearly polarized ultraviolet light is irradiated, and anisotropic micro-regions selectively oriented in different directions are formed in the linear photopolymerization material layer, forming a photoalignment m...

Embodiment 2

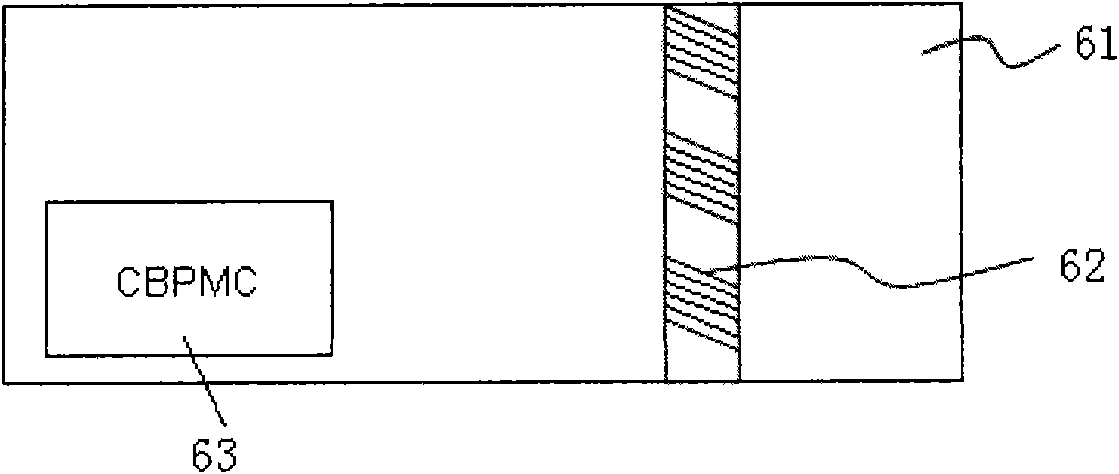

[0063] On the surface of the aluminum layer of the aluminum-plated BOPP substrate (substrate layer) 1, a protective layer is printed by gravure, and then the aluminum layer of the unprotected part is corroded with lye, washed with water, dried, and the inscribed text can be seen "CBPMC", forming local metal layer 2;

[0064] Coating and forming a photo-alignment material layer 3 and a liquid crystal polymer layer 4 on the surface of the metal layer 2 in the same process as in Example 1, and loading the hidden information "CHINA" in the liquid crystal polymer layer 4;

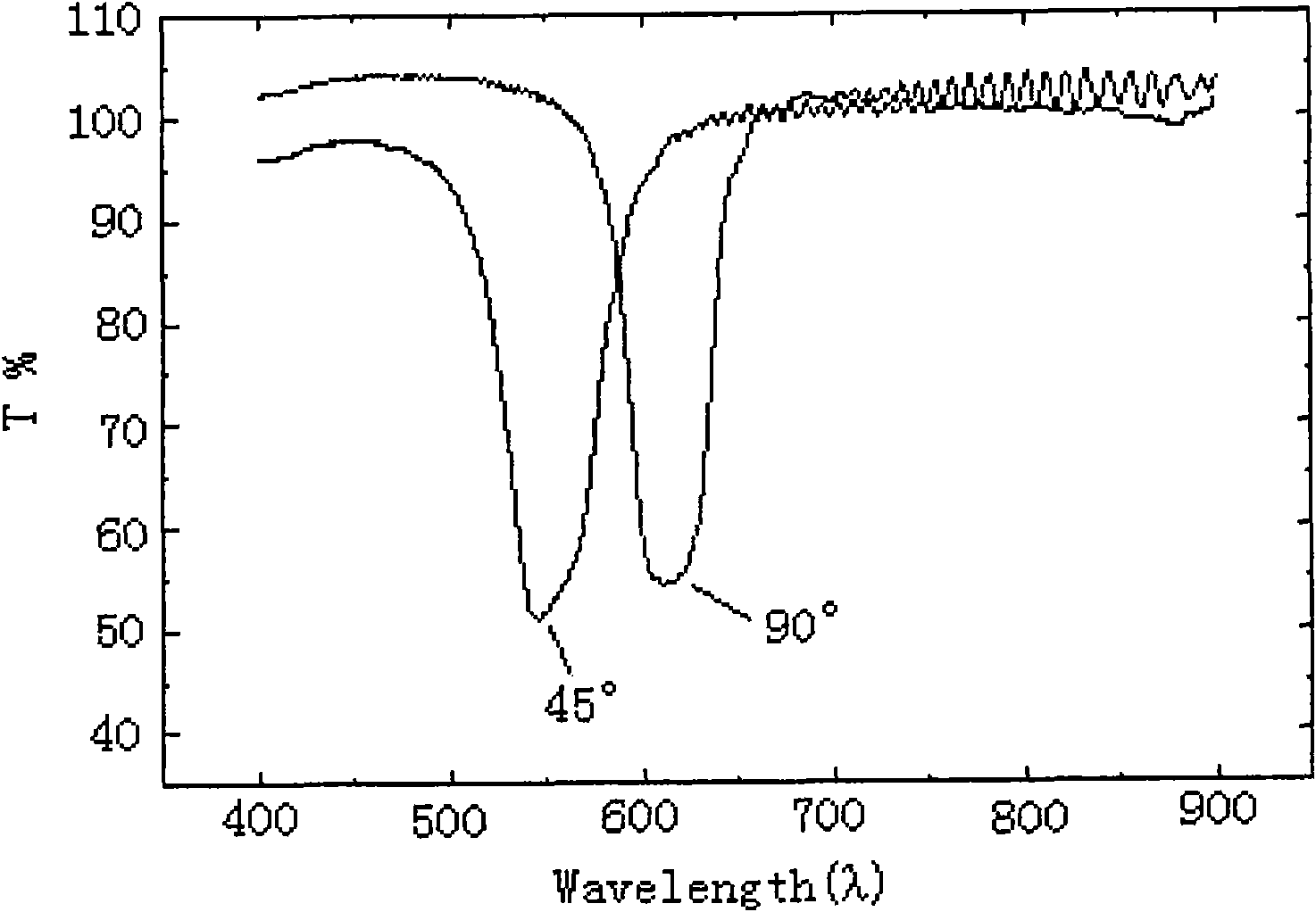

[0065] Coat the cholesteric liquid crystal solution on the other side of the BOPP substrate 1, dry and remove the solvent, and use ultraviolet light to cross-link and solidify the cholesteric liquid crystal under an inert atmosphere to form a cholesteric liquid crystal layer 6;

[0066] Then on the surface of the cholesteric liquid crystal layer 6, the overprinting appearance color is the same, and the dark infr...

Embodiment 3

[0070] Coating holographic molding glue on the surface of PET substrate (substrate layer) 1, drying to form a molding layer, processing the molding layer with a molding plate, and then vapor-depositing an aluminum layer on the surface of the molding layer to form a "BANK" text message Holographic layer 5;

[0071] Then, a protective layer is printed by gravure on the surface of the aluminum layer, the unprotected part of the aluminum layer is corroded with lye, washed with clear water, and dried to form a partial metal layer 2 with the text message "PEOPLE";

[0072] On the other side of the PET substrate 1, the photo-alignment material layer 3 and the liquid crystal polymer layer 4 are coated in the same manner as in Example 1, and the hidden information "CHINA" is loaded in the liquid crystal polymer layer 4;

[0073] Form the cholesteric liquid crystal layer 6 in the same manner as in Example 2 on the surface of the liquid crystal polymer layer 4, and then overprint hard ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com