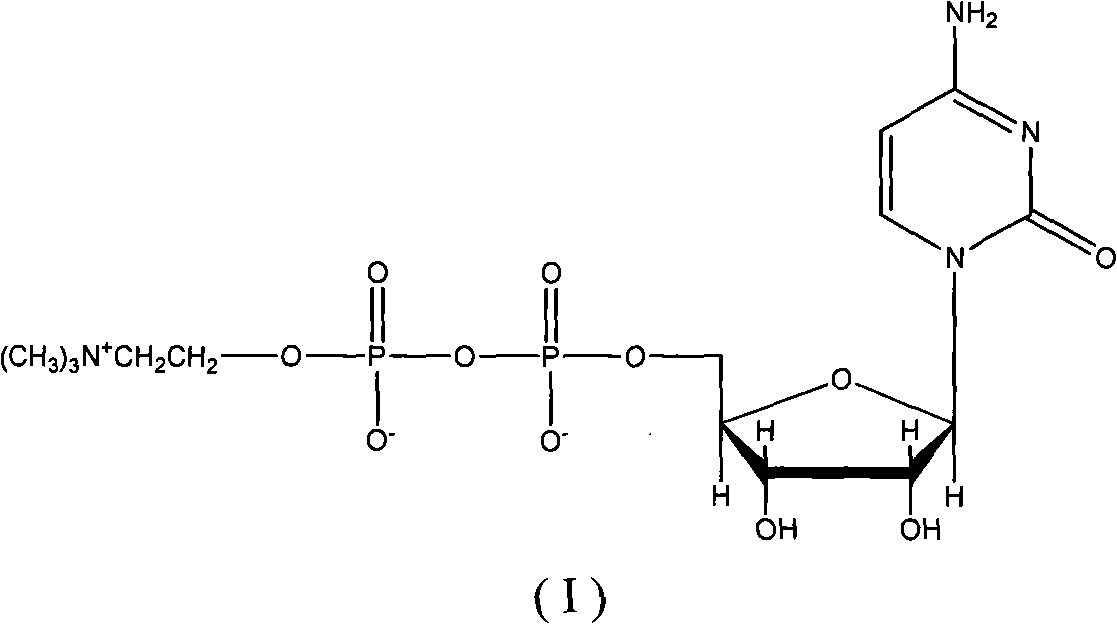

Method for separating purified cytidine diphosphate choline by hydrophobic chromatography

A technology for separation and purification of citicoline, applied in the field of biological separation, can solve the problems of high product loss rate, lengthy production process, and low separation efficiency, achieve short loss, increase product yield, and reduce separation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] According to the whole-cell catalytic synthesis method above, 15 L of CDP-choline conversion liquid was prepared, wherein the concentration of CDP-choline was 9.47 g / L.

[0029] The treatment process is as follows:

[0030] (1) Adjust the pH of the whole-cell catalytic conversion solution to 2.0 with hydrochloric acid to inactivate the enzyme, and remove solid impurities after centrifugation at 8000 rpm for 20 minutes. The centrifuged supernatant was processed by ultrafiltration, and the ultrafiltration permeate was collected; the ultrafiltration membrane was a polysulfone membrane, the molecular weight cut-off of the ultrafiltration membrane was 5000Dolton, and the working pressure of the ultrafiltration membrane was 1MPa.

[0031](2) Sodium chloride was added to the ultrafiltration permeate to prepare a column liquid containing 2.5 mol / L sodium chloride and 5 g / L CDP-choline, and the pH was adjusted to 4.0 with hydrochloric acid. The sulfonic acid-based polystyrene r...

Embodiment 2

[0034] According to the above whole-cell catalytic synthesis method, 15 L of CDP-choline conversion liquid was prepared, wherein the concentration of CDP-choline was 10.75 g / L.

[0035] The treatment process is as follows:

[0036] (1) Adjust the pH of the whole-cell catalytic conversion solution to 3.0 with hydrochloric acid to inactivate the enzyme, and remove solid impurities after centrifugation at 10,000 rpm for 20 minutes. The centrifuged supernatant was processed by ultrafiltration, and the ultrafiltration permeate was collected; the ultrafiltration membrane was a polysulfone membrane, the molecular weight cut-off of the ultrafiltration membrane was 3000Dolton, and the working pressure of the ultrafiltration membrane was 1.5MPa.

[0037] (2) Ammonium sulfate is added to the permeate of the ultrafiltration to prepare a column solution containing 0.01mol / L ammonium sulfate and 5g / L CDP-choline, and the pH is adjusted to 2.0 with hydrochloric acid, and the phosphoric acid-...

Embodiment 3

[0040] According to the whole-cell catalytic synthesis method above, 15 L of CDP-choline conversion solution was prepared, wherein the concentration of CDP-choline was 12.8 g / L.

[0041] The treatment process is as follows:

[0042] (1) Adjust the pH of the whole-cell catalytic conversion solution to 2.0 with hydrochloric acid to inactivate the enzyme, and remove solid impurities after centrifugation at 8000 rpm for 20 minutes. The centrifuged supernatant was processed by ultrafiltration, and the ultrafiltration permeate was collected; the ultrafiltration membrane was a polysulfone membrane, the molecular weight cut-off of the ultrafiltration membrane was 8000Dolton, and the working pressure of the ultrafiltration membrane was 0.5MPa.

[0043] (2) Potassium dihydrogen phosphate was added to the ultrafiltration permeate to prepare a column solution containing 1 mol / L potassium dihydrogen phosphate and 10 g / LCDP-choline, and the pH was adjusted to 4.0 with hydrochloric acid. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com