Halogen-free epoxy adhesive for polyethylene terephthalate (PET) protective film or insulation layer and preparation method thereof

An epoxy adhesive and insulating layer technology, applied in the direction of online phenolic epoxy resin adhesive, adhesive, epoxy resin glue, etc., can solve the problems of poor heat resistance, poor flame retardancy, and inability to meet the requirements of non-halogenation , to achieve the effect of high heat resistance

Active Publication Date: 2010-12-08

无锡宏仁电子材料科技有限公司

View PDF4 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since halogenated epoxy resin uses halogen elements in the resin for flame retardancy, it cannot meet the requirements of halogen-free

In addition, polyester resins are mainly divided into halogenated and halogen-free. The latter has poor flame retardancy or no flame retardancy, so the former is generally used, but halogenated polyester resins also use halogen elements in the resin for flame retardancy, so Can not meet the requirements of non-halogenated

At the same time, due to the poor heat resistance of polyester resin, it is easy to deform after being heated, and it is easy to soften and deform even at lower temperatures, and its flame resistance is poor, so it is difficult to meet the application requirements of FPC and FFC terminals for heat resistance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0023] A kind of halogen-free epoxy adhesive suitable for PET protective film or insulating layer disclosed by the present invention is made of the following raw materials according to the mass ratio:

[0024] Halogen-free epoxy resin 30~50,

[0025] Solvent 20~60,

[0026] Toughener 20~35,

[0027] Flame retardant 10~30,

[0028] Curing agent 1~5,

[0029] Accelerator 0.01~1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

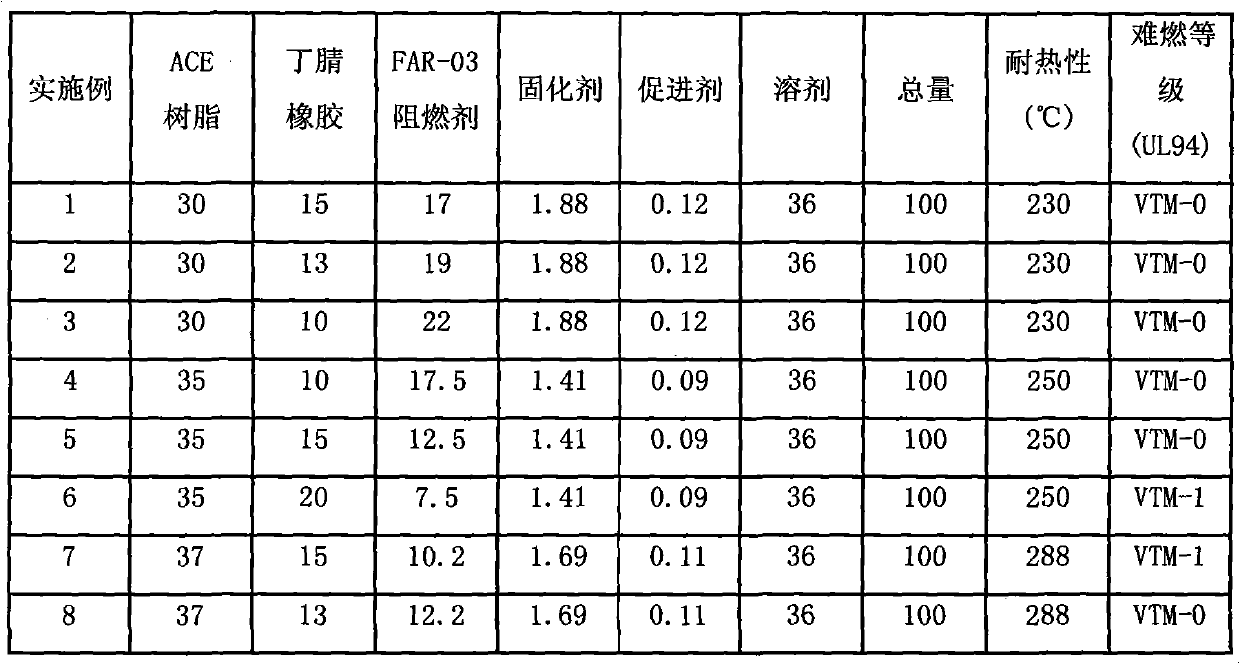

The invention discloses a halogen-free epoxy adhesive for a PET protective film or an insulation layer, which is prepared from the following raw materials in part by mass: halogen-free epoxy resin of 30 to 50, solvent of 20 to 60, flexibilizer of 20 to 35, flame retardant of 10 to 30, curing agent of 1 to 5 and promoter of 0.01 to 0.1. A preparation method of the halogen-free epoxy adhesive comprises the following steps of: adding the halogen-free epoxy resin and the solvent into a container according to a mass ratio of 100: 50, stirring till the mixed materials are dissolved completely and recoding the obtained product as a component A; adding the flexibilizer and the solvent into the container according to a mass ratio of 100: 100, stirring till the mixed materials are dissolved completely and recoding the obtained product as a component B; and mixing the component A, the component B, the flame retardant, the curing agent and the promoter according to a mass ratio of (45-60): (40-70): (10-30): (1-5): (0.01-0.1) and uniformly stirring the mixture to obtain the halogen-free epoxy adhesive. Tests show that the halogen-free epoxy adhesive has the heat-resistance temperature of 288 DEG C and the flame-resistance grade of UL94VTM-0 and meets the application requirements of flexible printed circuit (FPC) and flexible flat cable (FFC) terminals on heat resistance, insulation and flame resistance.

Description

technical field [0001] The invention relates to a halogen-free epoxy adhesive suitable for PET protective films or insulating layers, and relates to the raw material formula and preparation method of the halogen-free epoxy adhesive. Background technique [0002] In the prior art, the main resin used for PET (polyethylene terephthalate) protective film or insulating layer adhesive for FPC flexible circuit board or FFC flexible flat cable is generally prepared with halogen epoxy resin or polyester resin. . Since the halogen-containing epoxy resin uses the halogen element in the resin for flame retardancy, it cannot meet the halogen-free requirements. In addition, polyester resins are mainly divided into halogenated and halogen-free. The latter has poor flame retardancy or no flame retardancy, so the former is generally used, but halogenated polyester resins also use halogen elements in the resin for flame retardancy, so Can not meet the requirements of non-halogenation. At ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J163/00C09J163/02C09J163/04C09J11/08C09J9/00

Inventor 邹威施忠仁杨丰彰向必军芦卫东徐群星

Owner 无锡宏仁电子材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com