Power lithium ion battery and production method thereof

A lithium-ion battery and power technology, applied in the field of lithium-ion batteries, can solve the problems of large internal resistance of the battery, affecting the safety performance of the battery, and low utilization rate of the active material of the battery, so as to improve the electrical performance and safety performance, and meet the needs of high-current discharge. requirements, and the effect that is conducive to large current discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

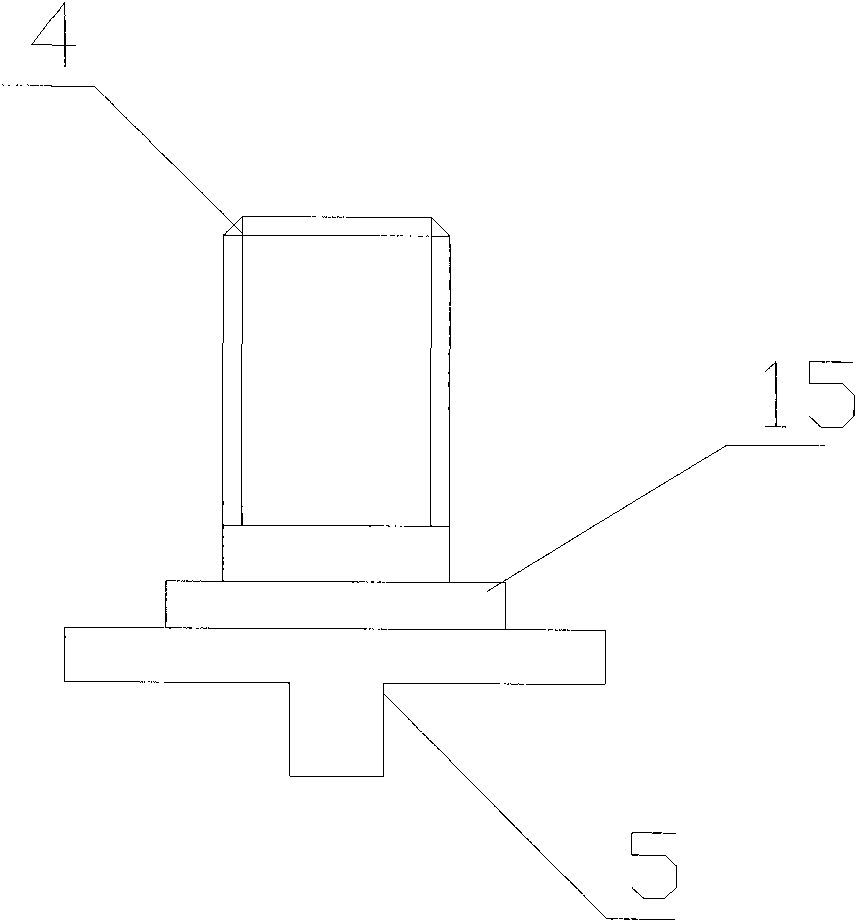

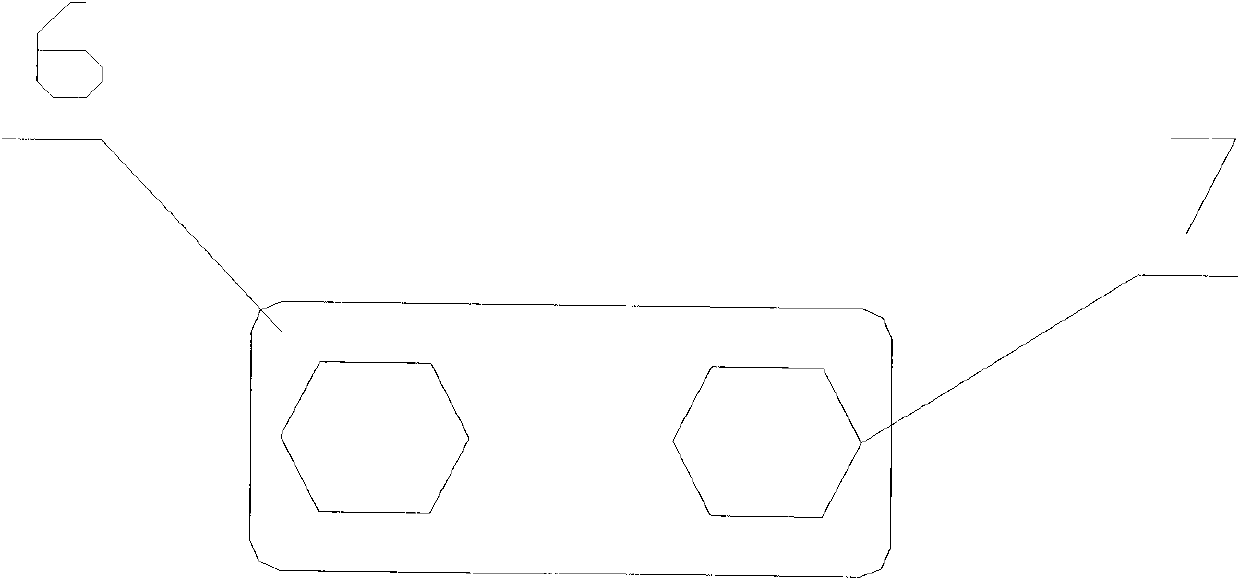

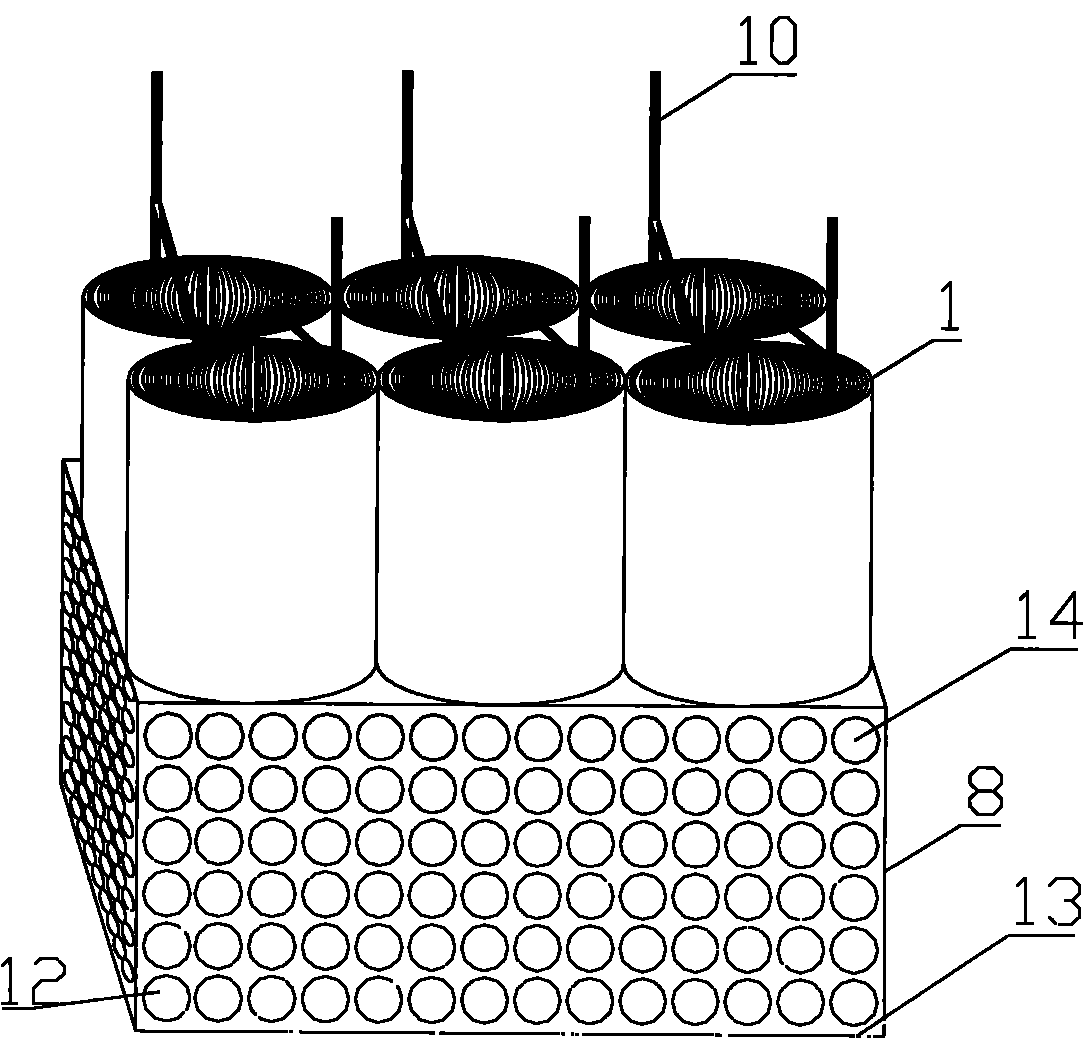

[0034] Such as figure 1 , figure 2 As shown, a power lithium-ion battery includes a casing 2, a battery core sealed in the casing 2, and upper and lower cover plates of the battery. The upper cover plate 3 is provided with positive and negative poles. The battery core is composed of cylindrical small cells 1 connected in parallel. There are positive and negative pole ears 10 on it. A square case 2 is used for the battery.

[0035] The present invention uses battery cores formed by parallel connection of cylindrical small battery cells 1, which can meet the requirements of high-current discharge, and the performance of the entire single battery is stable, and the battery core does not need a hot-pressing and shaping process before b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com