Thin double-wire digital soft switch inverter welding power source system and control method thereof

A technology of inverter welding power supply and soft switch, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of strong electromagnetic interference at the welding site, difficulty in eliminating electromagnetic interference of welding wire, and high communication speed requirements, so as to improve Electromagnetic compatibility and reliability, improve welding quality, reduce the effect of electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

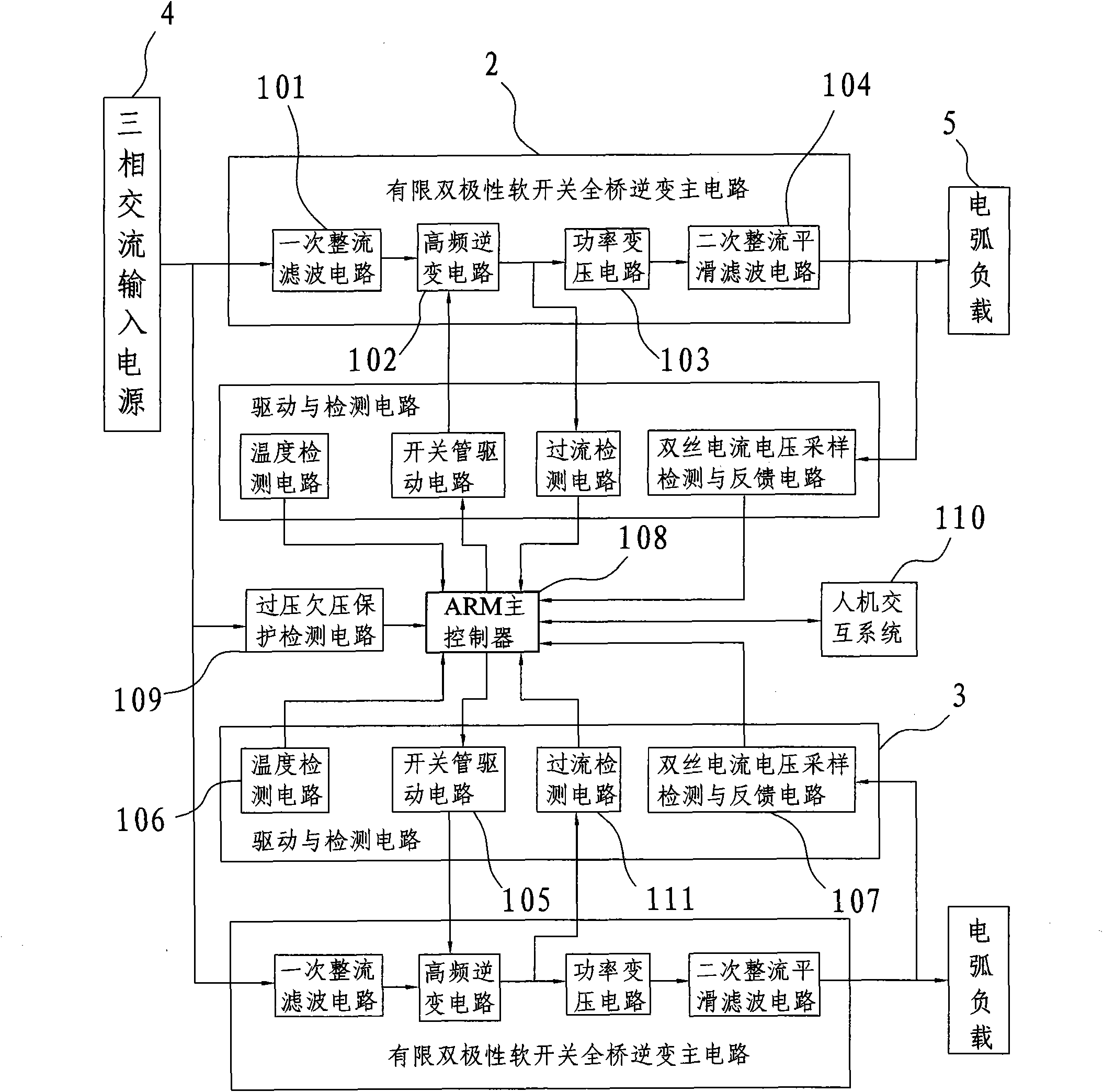

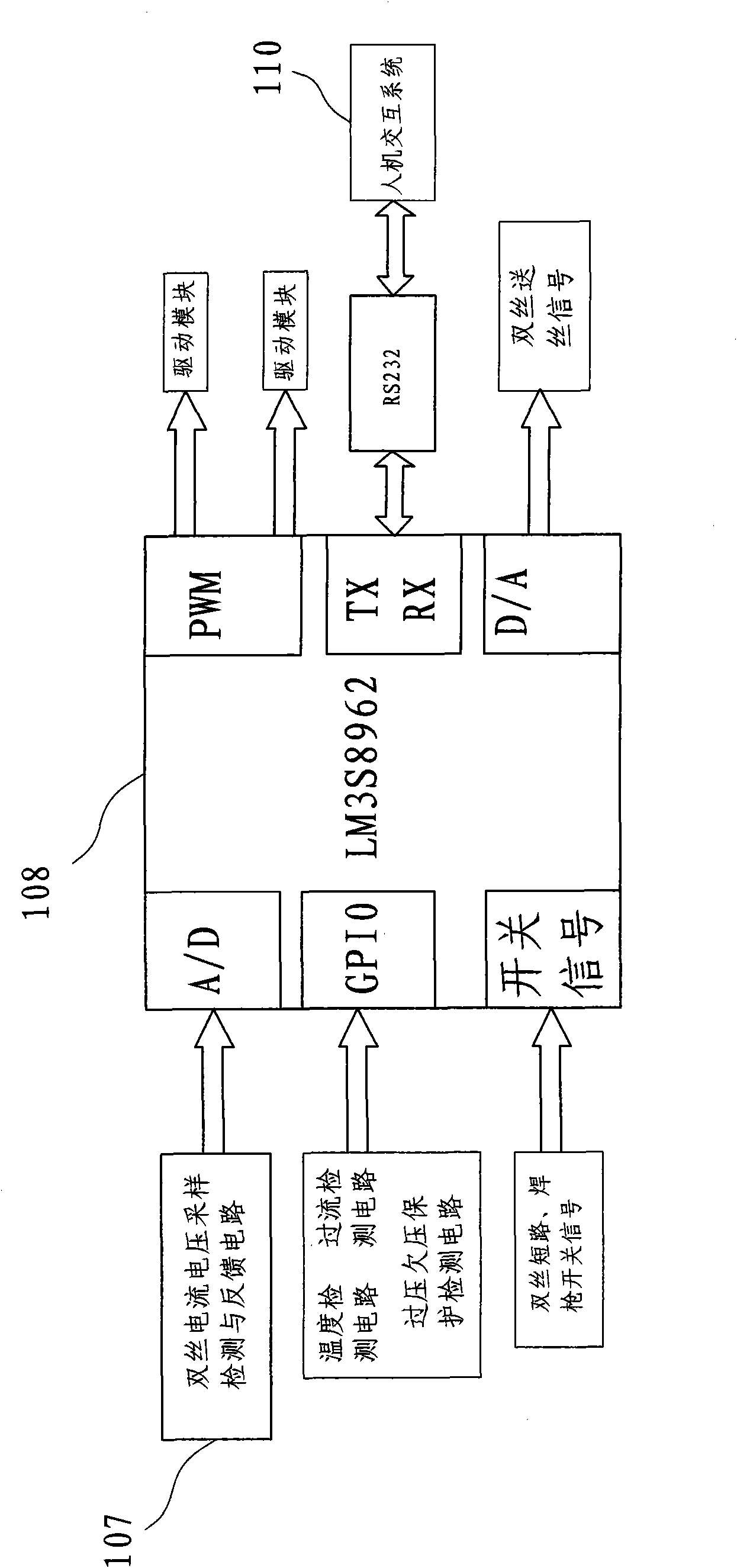

[0047] A digital soft-switching inverter welding power supply system for thin twin wires, such as figure 1 As shown, it includes an over-voltage and under-voltage protection detection circuit 109 installed in the same welding power supply chassis with an integrated structure, a human-computer interaction system 110, an ARM main controller 108 with a welding process expert database software system built in, two A finite bipolar soft-switching full-bridge inverter main circuit 2 with the same circuit structure, and a drive and detection circuit 3 with the same circuit structure.

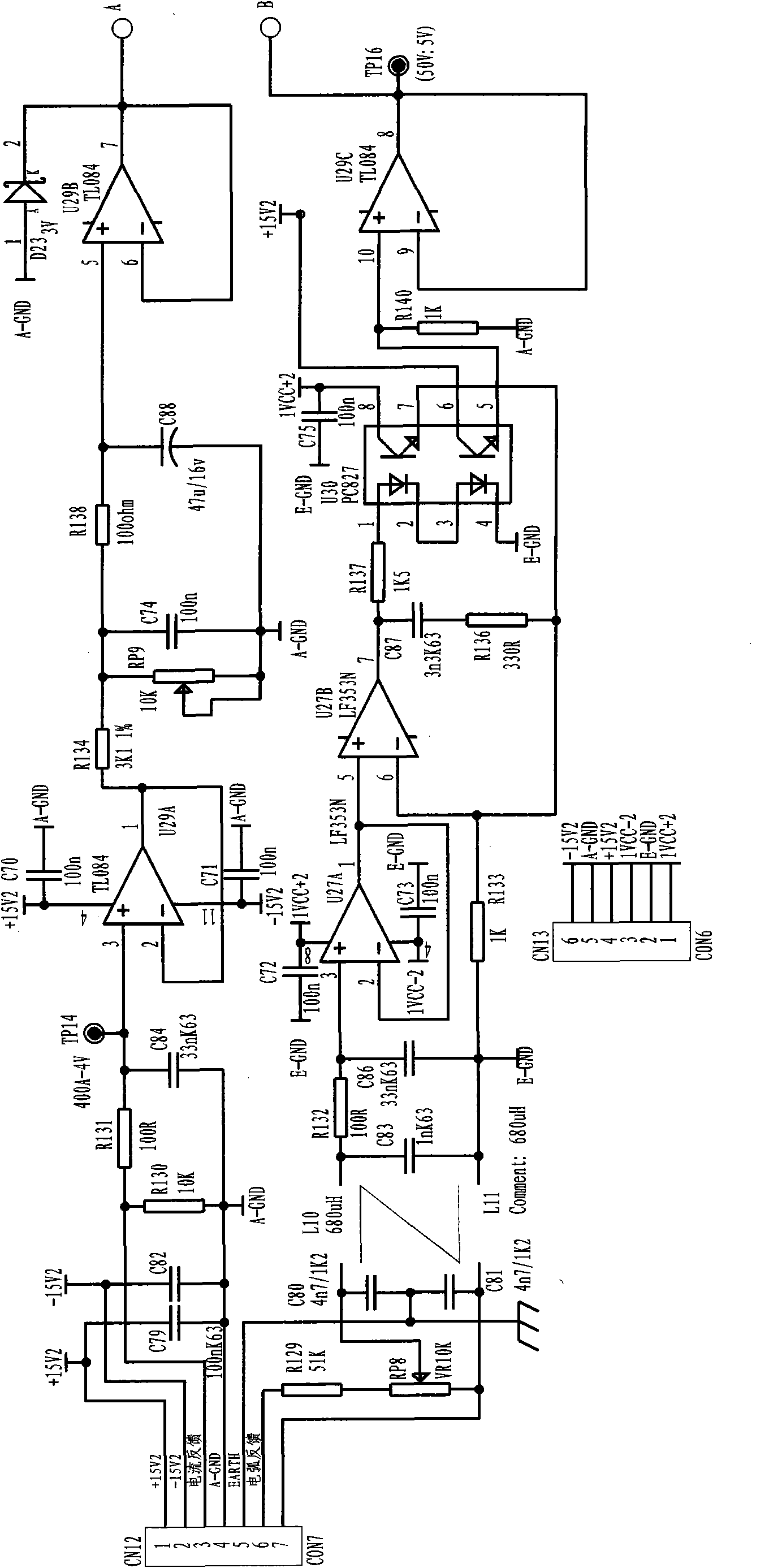

[0048] Wherein, the limited bipolar soft-switching full-bridge inverter main circuit 2 uses an insulated gate bipolar transistor IGBT as a switching element; the limited bipolar soft-switching full-bridge inverter main circuit 2 includes sequentially connected primary rectifier A filter circuit 101 , a high frequency inverter circuit 102 , a power transformer circuit 103 , and a secondary rectification...

Embodiment 2

[0075] Such as Figure 8 As shown in the present invention, a control method of a thin twin wire digital soft-switching inverter welding power supply system comprises the following steps:

[0076] Step A, start the system and initialize the system parameters;

[0077] Step B, the ARM main controller 108 sends a welding start signal to the human-computer interaction system 110, and at the same time the ARM main controller 108 receives and acquires welding parameters;

[0078] Step C, the ARM main controller 108 invokes the arc striking pulse waveform function to start arc striking;

[0079] Step D, if arc striking is unsuccessful, return to step C;

[0080] If the arc ignition is successful, enter the normal welding process and enter step E;

[0081] Step E, judging the selected welding method, and executing the corresponding control subroutine according to the selected welding method, including:

[0082] If the welding method is pulse MIG welding, enter the pulse MIG weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com