Primary sludge fermentation pretreatment system for improving performances of dephosphorization and denitrification on town sewage

A pretreatment technology for urban sewage, applied in the field of urban sewage pretreatment system, can solve the problems of affecting the ability of biological phosphorus removal and denitrification, low carbon-nitrogen ratio of influent, adverse effects of biological phosphorus removal and denitrification process unit treatment efficiency, etc. , to achieve the effects of complete functions, reduced engineering cost and operating cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

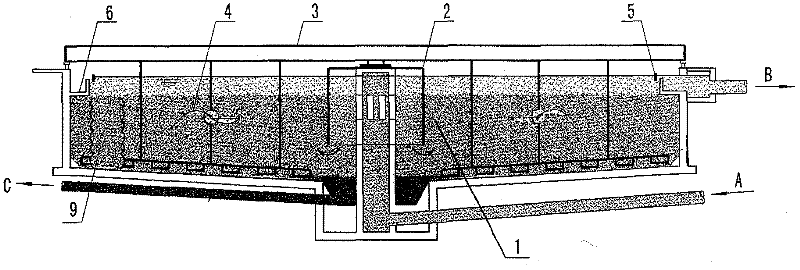

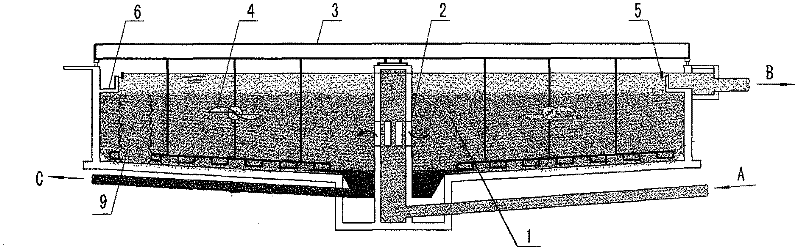

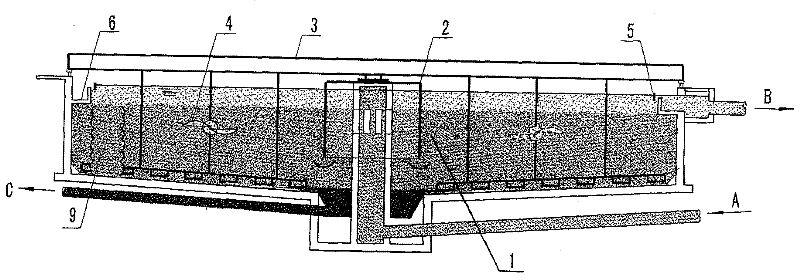

[0019] Such as figure 1 and figure 2 As shown, in this specific embodiment, the sewage primary sedimentation fermentation tank pretreatment system of the present invention is composed of a primary sedimentation fermentation tank (1) integrating primary sedimentation and fermentation functions, an inlet water distribution system (2), and installed in The scraper-suction bridge frame (3) on the top of the primary sedimentation fermentation tank, several low-speed propellers or submersible mixers installed on the scraper-suction bridge frame, the outlet weir plate (5) located on the upper part of the primary sedimentation fermentation tank, and the outlet water collection tank ( 6) and the mud discharge subsystem located at the bottom of the primary settling fermentation tank; wherein, the central tube water distributor is connected to the grille at the front end and the outlet A for grit treatment through pipelines, and the effluent collection tank (6) is connected to the subse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com