A/A-MBR intensified combined device for denitriding and dephosphorizing and process thereof

A combined device, nitrogen and phosphorus removal technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. The effect of mud concentration and stable denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

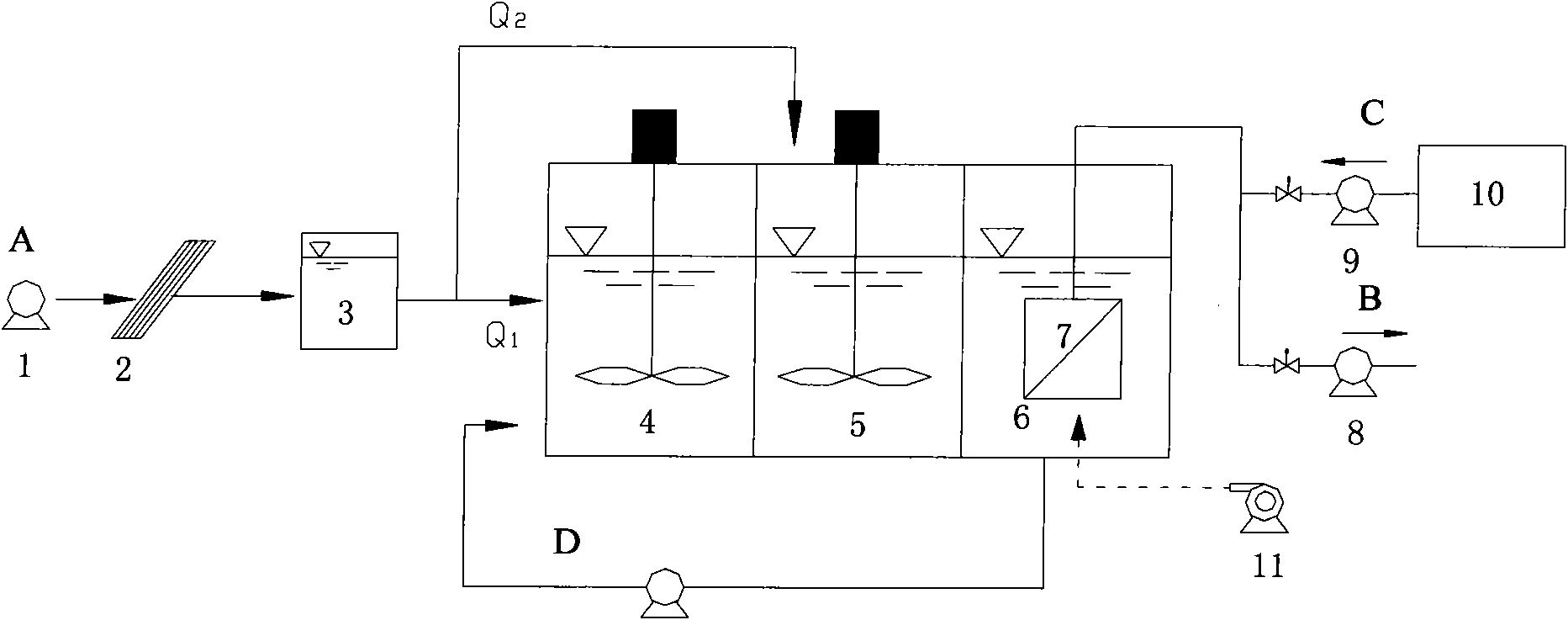

[0013] A / A-MBR enhanced nitrogen and phosphorus removal combined device, the device includes inlet pump 1, grid 2, regulating tank 3, anoxic tank 4, anaerobic tank 5, MBR tank 6, membrane module 7, outlet pump 8, The backwash pump 9, the backwash water tank 10 and the blower 11, the inlet pump, grille, regulating tank, anoxic tank, anaerobic tank, MBR tank and outlet pump are sequentially connected by pipelines, and the pipeline connecting the regulating tank and the anoxic tank There is a pipeline connected to the anaerobic tank, the membrane module 7 is set in the MBR tank 6, the blower is connected to the MBR tank, the MBR tank is provided with a return pipeline connected to the anoxic tank, and the backwash water tank is connected in parallel to the MBR tank through the backwash pump On the connecting pipe with the outlet pump, the membrane module is an immersed curtain membrane with a molecular weight cut-off of 150,000 Daltons. The average pore diameter is 0.02μm, the di...

Embodiment 2

[0015] After the sewage is lifted by the water inlet pump, it enters the regulating tank after being filtered by the grid, then enters the anoxic tank and the anaerobic tank, and finally enters the MBR tank, and the water is discharged after membrane separation. According to the ratio of 1:1 distribution, at the same time, the mixed solution in the MBR tank is returned to the anoxic tank according to the reflux ratio of 200%, and the sludge age is not less than 15d; Oxygen tank 1.6, MBR tank 6.0; mixed liquid suspended solids concentration (mg / L): anoxic tank 3000-4000, anaerobic tank 3000-4000, MBR tank 7000-8000; dissolved oxygen (mg / L): anoxic tank 0.5, anaerobic pool<0.2, MBR pool 2.0; pH value: anoxic pool 7.5~8.0, anaerobic pool 7.2~7.5, MBR pool 7.2~7.5.

Embodiment 3

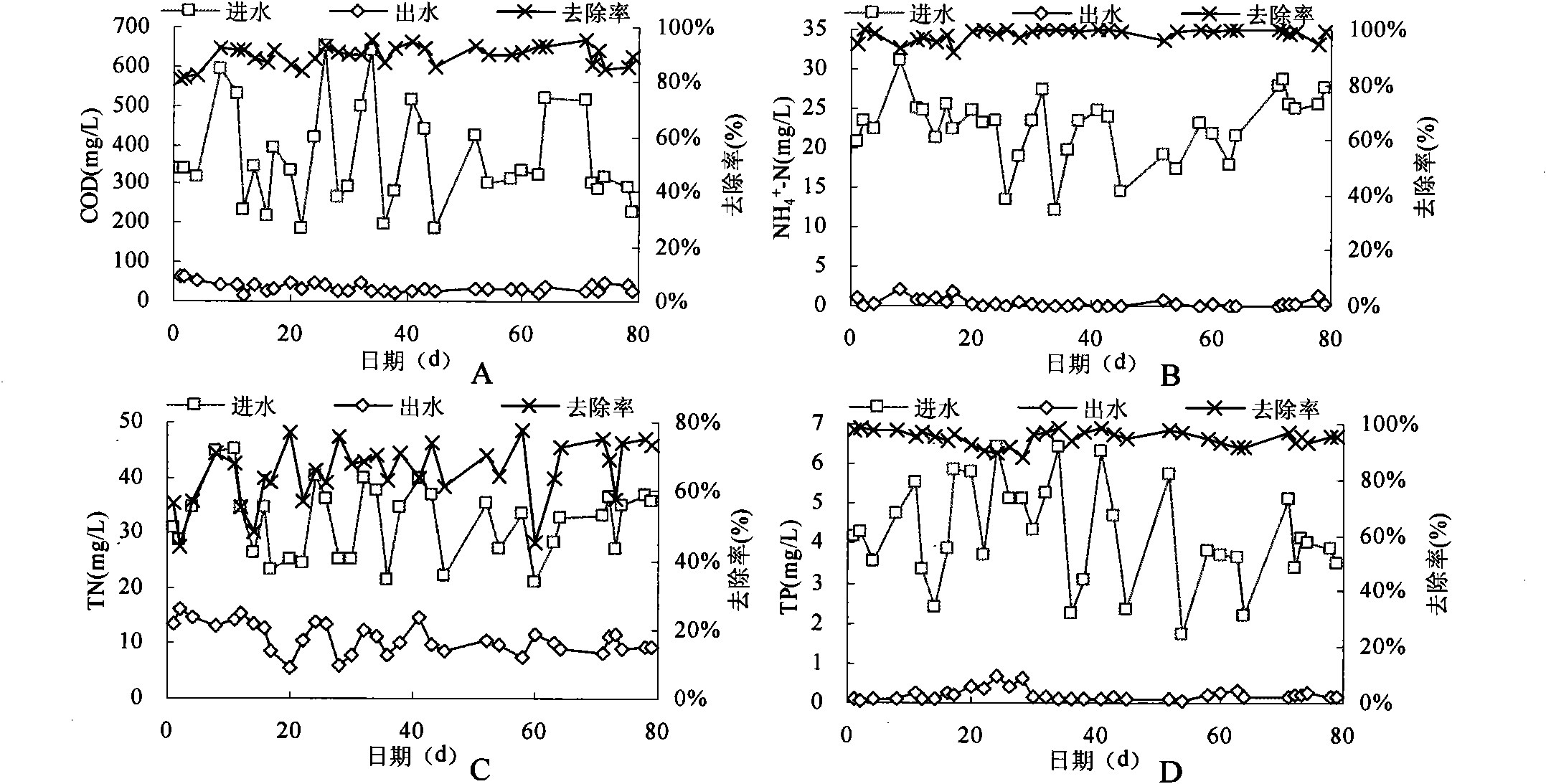

[0017]The research experiment took the effluent of the grit chamber of a certain urban sewage treatment plant as the water inlet condition, and took the A / A-MBR process technology as the research object. By controlling different test conditions, a reasonable and effective enhanced nitrogen and phosphorus removal technology was finally found.

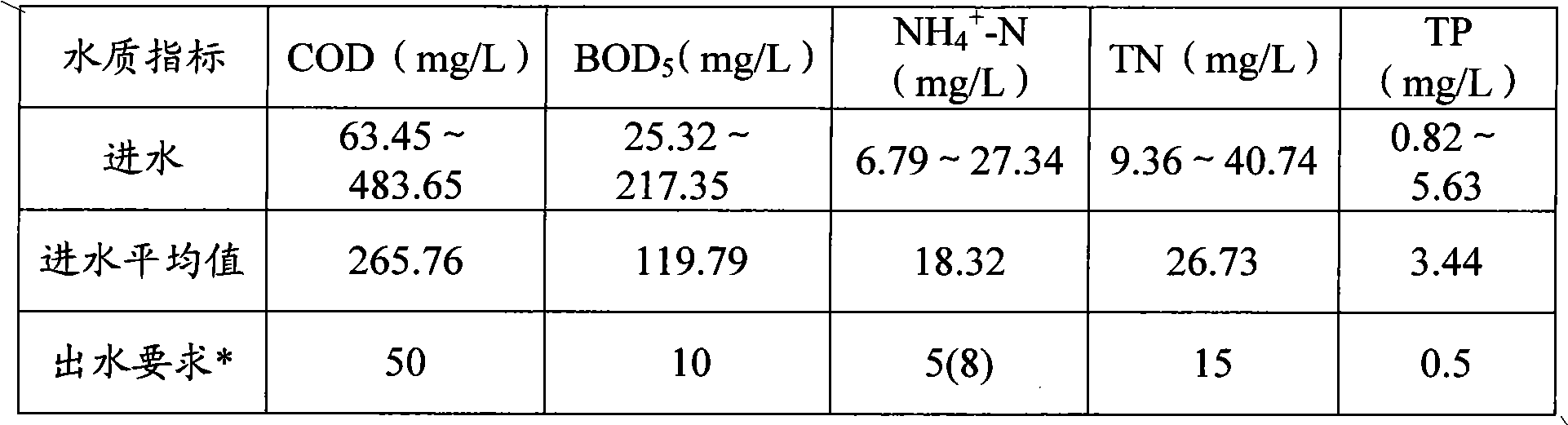

[0018] (1) The experiment was carried out in an urban sewage treatment plant, and the experimental design and installation of a pilot-scale device (2m 3 / h, such as figure 1 ). The influent of the device is the effluent of the cyclone grit chamber of the urban sewage treatment plant. The specific water quality indicators are shown in Table 1. Experimental process such as figure 1 , the operation of the A / A-MBR combined process is: after the raw water is lifted by the submersible sewage pump, it enters the regulating tank after passing through the fine grid and disc filter, then enters the anoxic zone, the anaerobic zone, and finally en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com