Glassfiber-reinforced hydrolysis-resistant low-warpage nylon 66 composite material and preparation method thereof

A composite material, anti-hydrolysis technology, applied in the field of modified polyamide, can solve problems such as poor dimensional stability, achieve high strength, improve easy warping deformation, good processability and appearance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

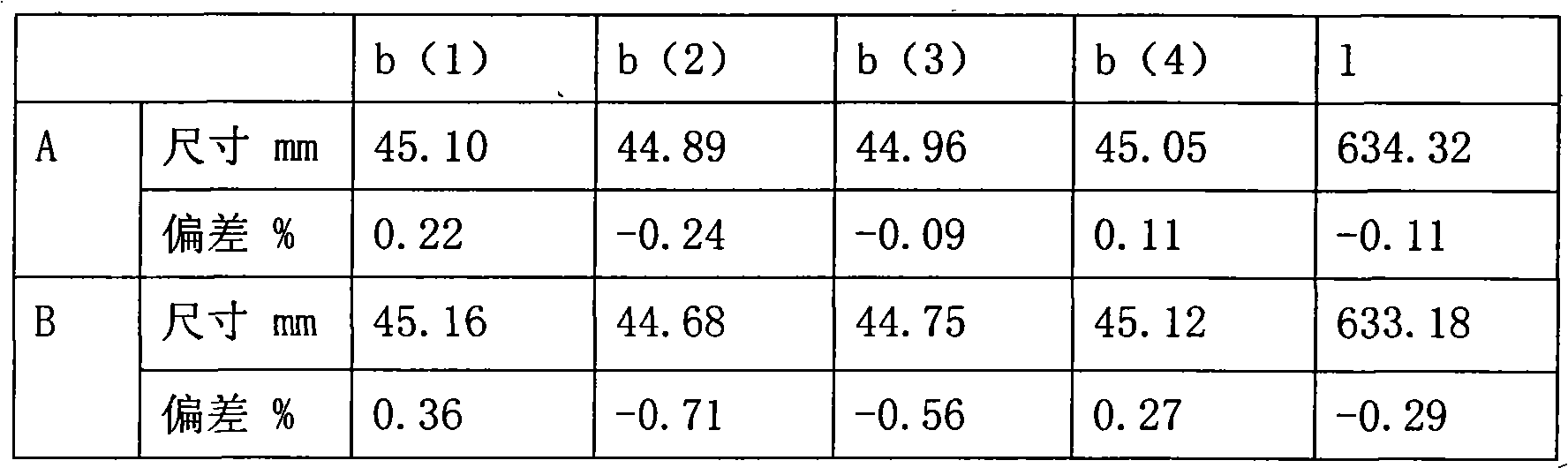

Image

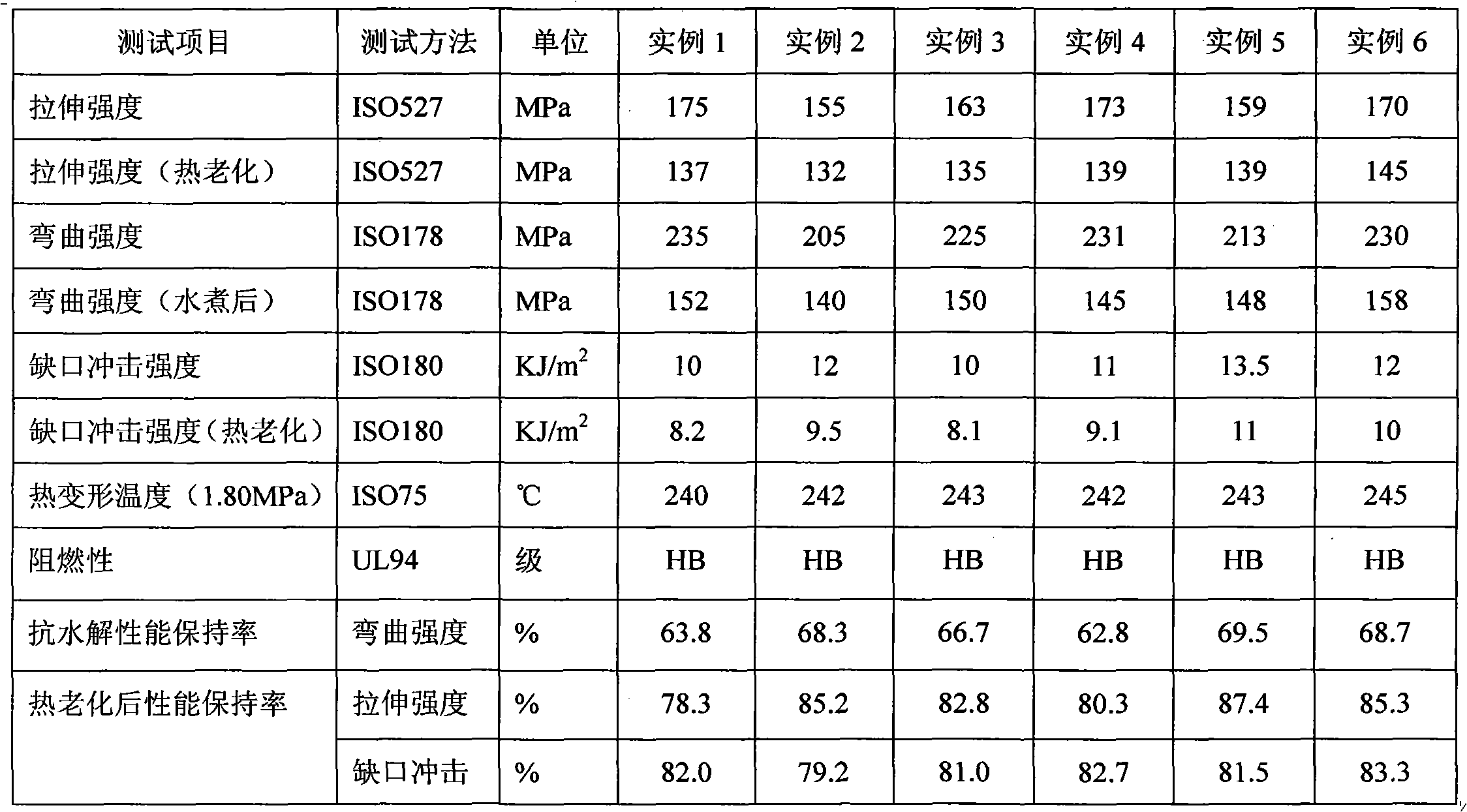

Examples

Embodiment 1

[0037] The resin intrinsic viscosity of nylon 66 is: 2.3-3.2, 65 parts by weight;

[0038] Alkali-free hydrolysis-resistant glass fiber, the diameter of the glass fiber is 9-13 μm, 30 parts by weight;

[0039] Hollow ceramic microspheres: 1100 mesh, 2 parts by weight;

[0040] Anti-hydrolysis and thermal stabilizer: Stabaxol-P (polycarbodiimide, produced by German Bayer Company), 0.5 parts by weight;

[0041] Compatibilizer: MAH (maleic anhydride) grafted EPDM (ethylene propylene diene rubber) with a graft rate of 0.8%, 1 part by weight;

[0042] Other additives: oxane coupling agent: KH560, antioxidant: compound of 1098 and 168, release agent: calcium stearate, 1.5 parts by weight in total according to (1:1:1 weight ratio).

Embodiment 2

[0044] The resin intrinsic viscosity of nylon 66 is: 2.3-3.2, 60.5 parts by weight;

[0045] Alkali-free hydrolysis-resistant glass fiber, the diameter of the glass fiber is 9-13 μm, 30 parts by weight;

[0046] Solid glass microspheres: 1600 mesh, 2 parts by weight;

[0047] Anti-hydrolysis and thermal stabilizer: Stabaxol-P, 2 parts by weight;

[0048] Compatibilizer: 1% MAH grafted POE, 4 parts by weight

[0049] Other additives: oxane coupling agent: KH560, antioxidant: compound of 1098 and 168, release agent: calcium stearate, 1.5 parts by weight in total according to (1:1:1 weight ratio).

Embodiment 3

[0051] The resin intrinsic viscosity of nylon 66 is: 2.3-3.2, 62.5 parts by weight;

[0052] Alkali-free hydrolysis-resistant glass fiber, the diameter of the glass fiber is 9-13 μm, 30 parts by weight;

[0053] Ultrafine hollow glass beads: ≥3000 mesh, 3 parts by weight;

[0054]Anti-hydrolysis and thermal stabilizer: Stabaxol-P, 1 part by weight;

[0055] Compatibilizer: 1% MAH grafted POE, 2 parts by weight

[0056] Other additives: oxane coupling agent: KH560, antioxidant: compound of 1098 and 168, release agent: wax,

[0057] According to (weight ratio of 1:1:1), a total of 1.5 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com