Metal surface treatment method for enforcing condensation heat transfer

A metal surface treatment and metal technology, applied in the field of metal surface treatment, can solve the problems of high cost, reduce surface free energy, etc., and achieve the effects of long life, good stability and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Metal surface treatment of oxygen-free copper:

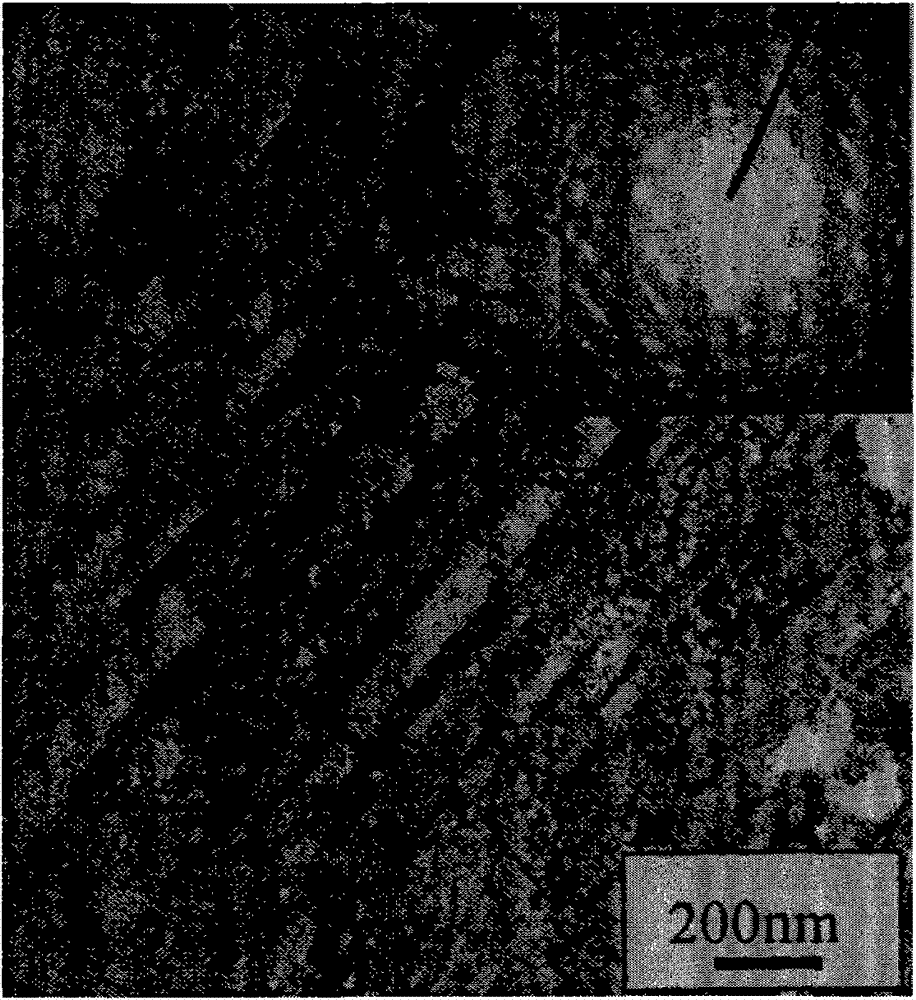

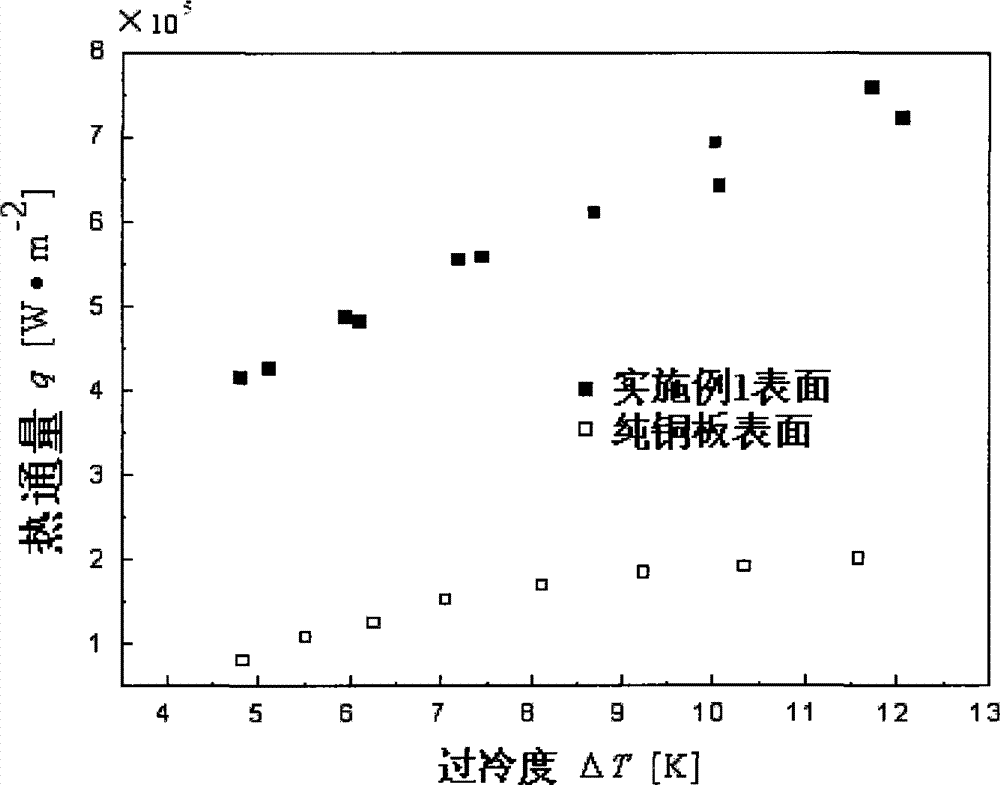

[0028] Roll an oxygen-free pure copper T2 flat plate (50mm×50mm) with a roll until the trace of the roll covers the whole oxygen-free pure copper plate, repeat the above rolling 120 times. The method of each rolling is: fix the metal on the rolling mill device, use liquid nitrogen as the cooling medium, and start rolling when the temperature of the metal surface reaches 77K; Move horizontally in the axial direction, the moving speed is 12mm / min, the revolution speed is 180rpm, and the temperature of the metal surface is kept at 77K during the rolling process. The transmission electron microscope photo of the surface of the copper plate after rolling is shown in figure 1 , it can be seen from the figure that its surface is mainly composed of nano-twinned bundles, and the selected area electron diffraction pattern shows that the nano-grains have random orientation. Based on statistical measurements of the grain size, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com