Precast concrete inside heat insulation wall body

A technology for thermal insulation walls and prefabricated concrete, applied to walls, building components, buildings, etc., can solve the problems of large holes in EPS boards, easy loosening and damage of joint parts, and weak pull-out resistance of concrete, so as to improve the overall structure Strength, reduce cold and heat bridge phenomenon, improve the effect of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

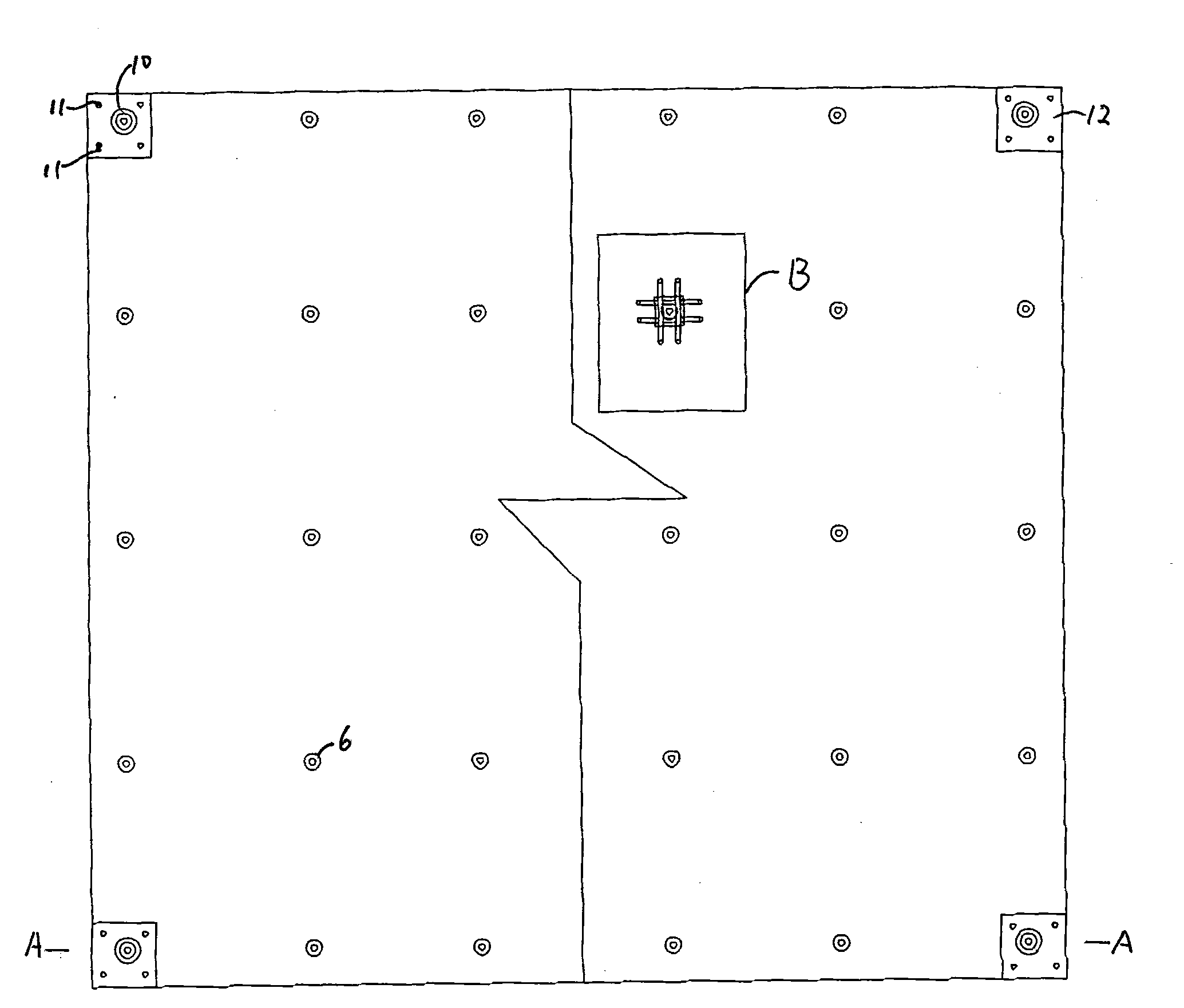

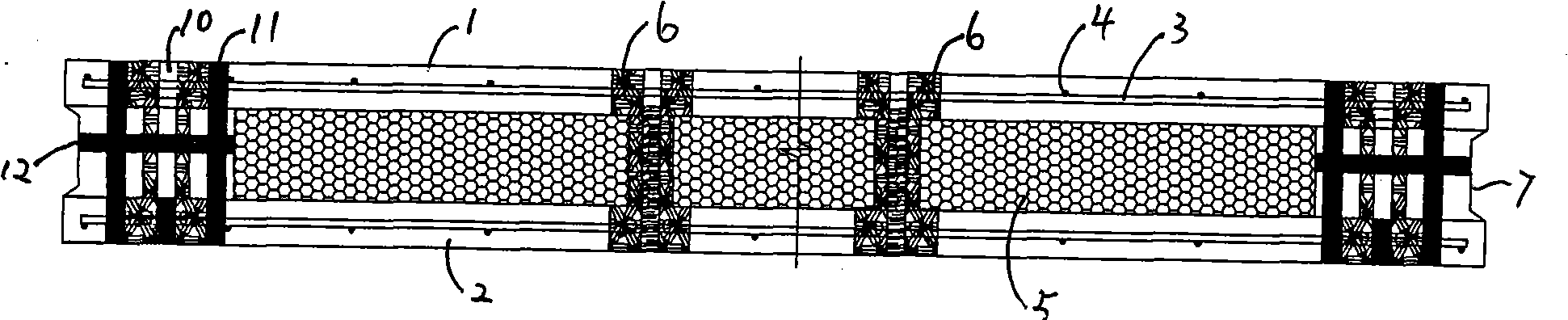

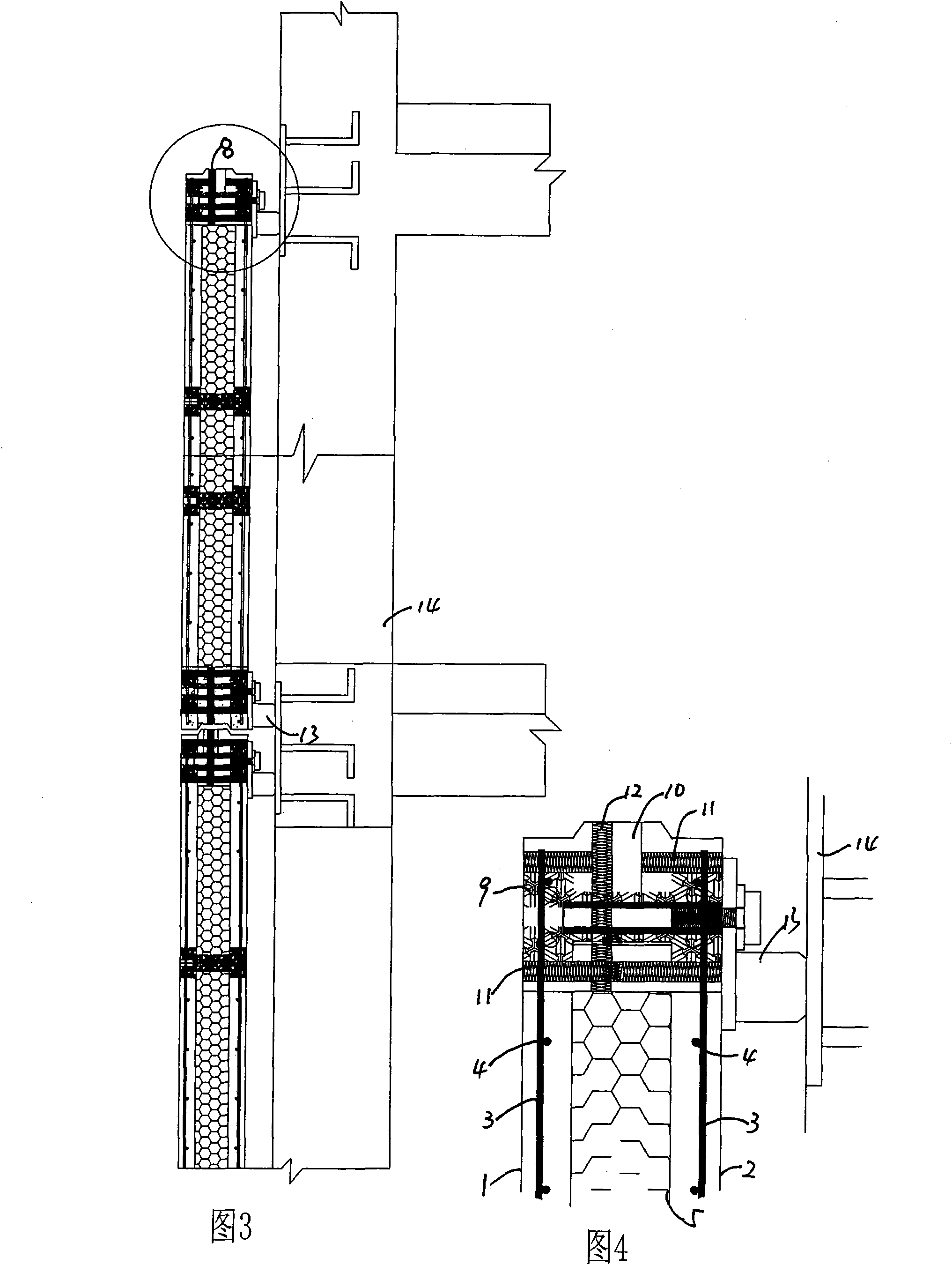

[0024] Embodiment: Referring to the accompanying drawings, the prefabricated reinforced concrete inner (self) thermal insulation wall includes reinforced concrete inner and outer wall panels 1 and 2 with a thickness of 5 cm on each side, and a 10 cm thick EPS board insulation layer 5 (wall insulation layer 5) between the inner and outer concrete wall panels. The total thickness of the body is 20cm), and there are FRP connectors 6 between the inner and outer wall panels at a distance of 50*50cm to form an integral prefabricated reinforced concrete inner insulation wall. Inside and outside the concrete wall panels, there are reinforcement meshes composed of longitudinal steel bars 3 and transverse steel bars 4 (the design of the steel mesh is based on the strength requirements of the wall panels); The enlarged heads at both ends are passed through and fixed by the steel bars of the inner and outer wall panels ( figure 1 B), protruding into the inner and outer wall panels without...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com