Method for increasing bonding force between conductor and non-conductive polymer dielectric layer in substrate of printed circuit board

A technology of printed circuits and conductors, applied in the secondary treatment of printed circuits, improvement of metal adhesion of insulating substrates, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

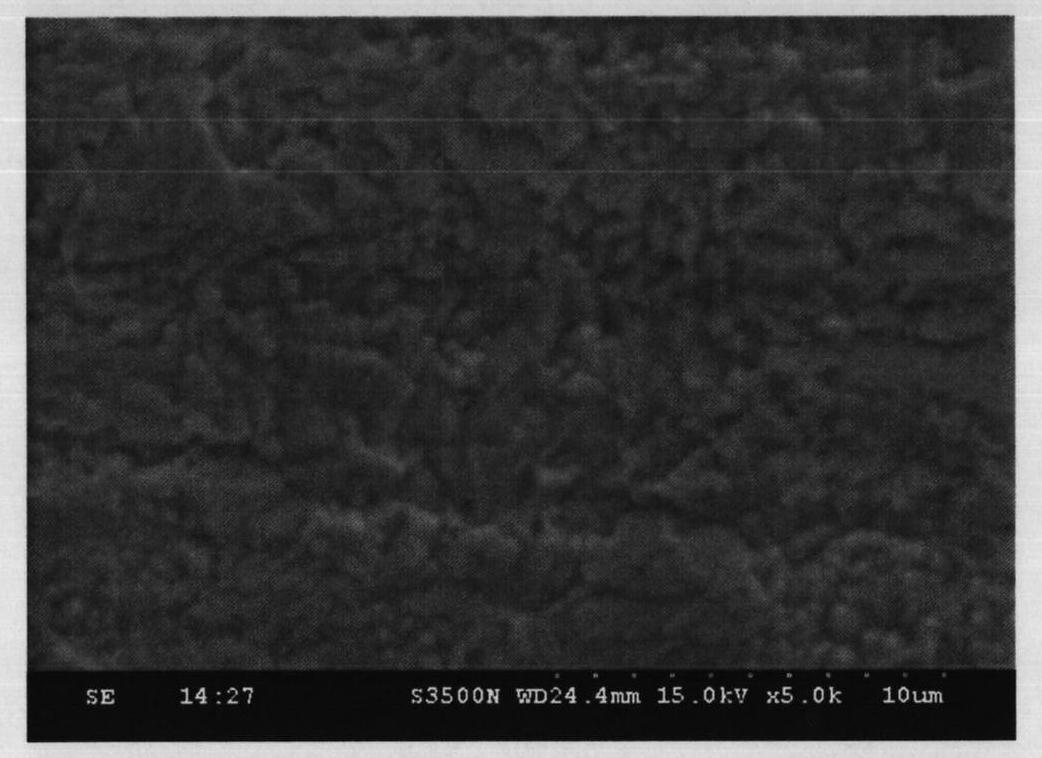

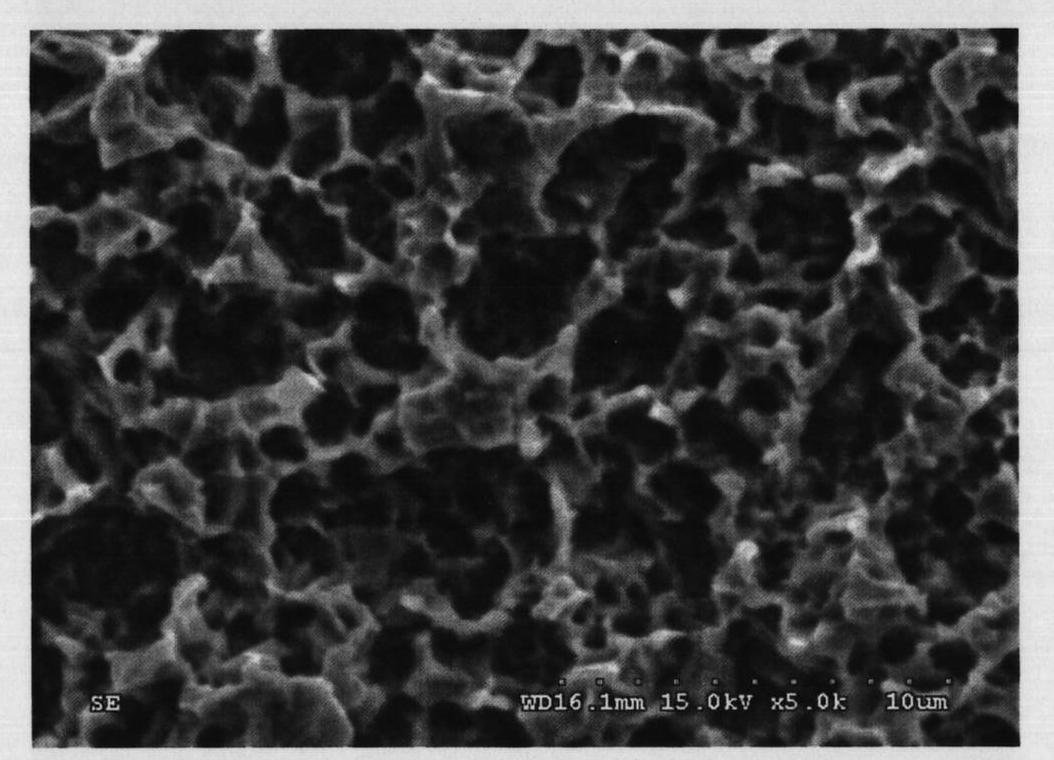

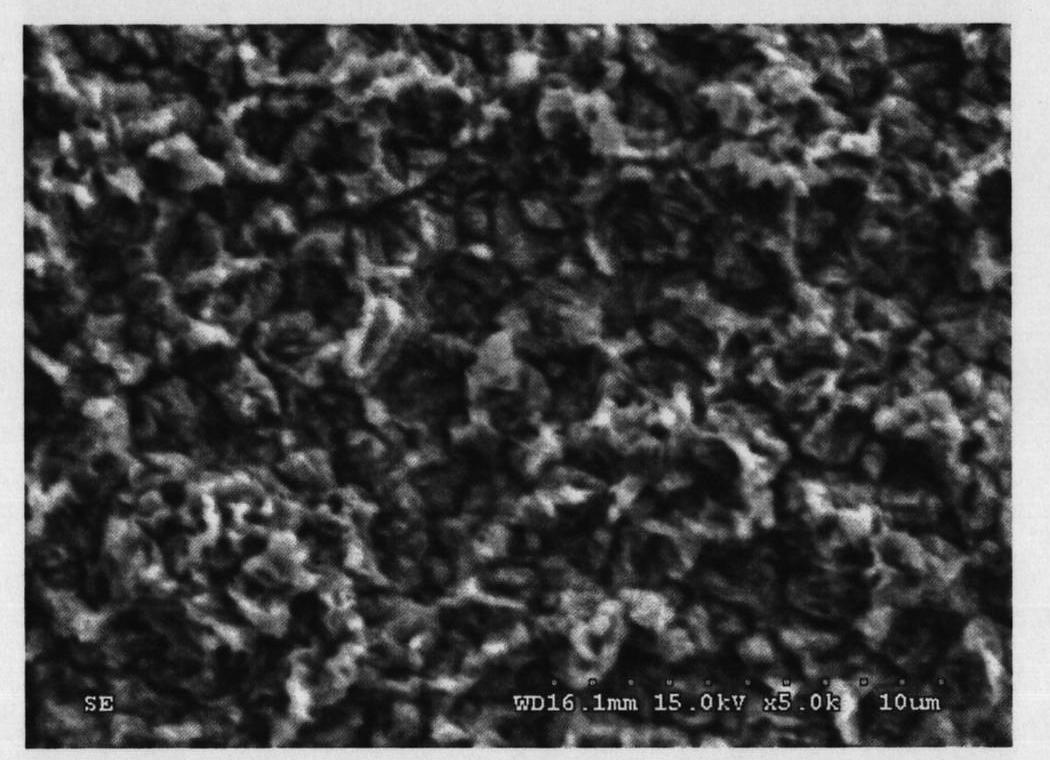

[0066] With the development of electronic products in the direction of thinner and lighter, coupled with dense electronic circuits, the roughness of the inner metal plate, that is, the conductor, is reduced, which in turn leads to the reliability of the bonding force. On the other hand, halogen-free flame retardants gradually replace halogen flame retardants and become the main substrate of printed circuits. At present, non-conductive polymer dielectric layer materials commonly used in the electronics industry have FR-4, insulation, halogen-free, High Tg Features, mainly made of glass fiber and epoxy resin or phenol resin, such as polytetrafluoroethylene (PTFE), epoxy resin (EPOXY RESIN), polyimide (POLYIMIDE), Polycyanate resin (POLYCYANATE ESTER), butylene terephthalate resin (BUTADIENE TEREPHTHALATE RESIN) or a mixture of the above materials, etc. In order to improve the metal plate, that is, the conductor, the surface roughness and the bonding force, the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com