Method for producing medium and small aperture seamless steel tube by reducing and rolling hollow continuous cast tube blank

A technology for reducing and rolling seamless steel pipes, which is applied in the direction of metal rolling, metal rolling, metal rolling racks, etc., and can solve the problems of increasing steel pipe wall thickness deviation, production line capacity limitation, and affecting metal yield, etc. problem, to achieve the effect of increasing the length of the ruler, reducing the perforation process and increasing the production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Outer diameter and wall thickness: φ400mm*120mm hollow continuous casting slab

[0023] Blank length: 8000mm

[0024] Billet weight: 5016kg

[0025] Finished product specification: 73mm*5.5mm

[0026] Finished product length: 12m*60=720m

[0027] Baking temperature: 1150°C

[0028] Rolling start temperature: 1100℃

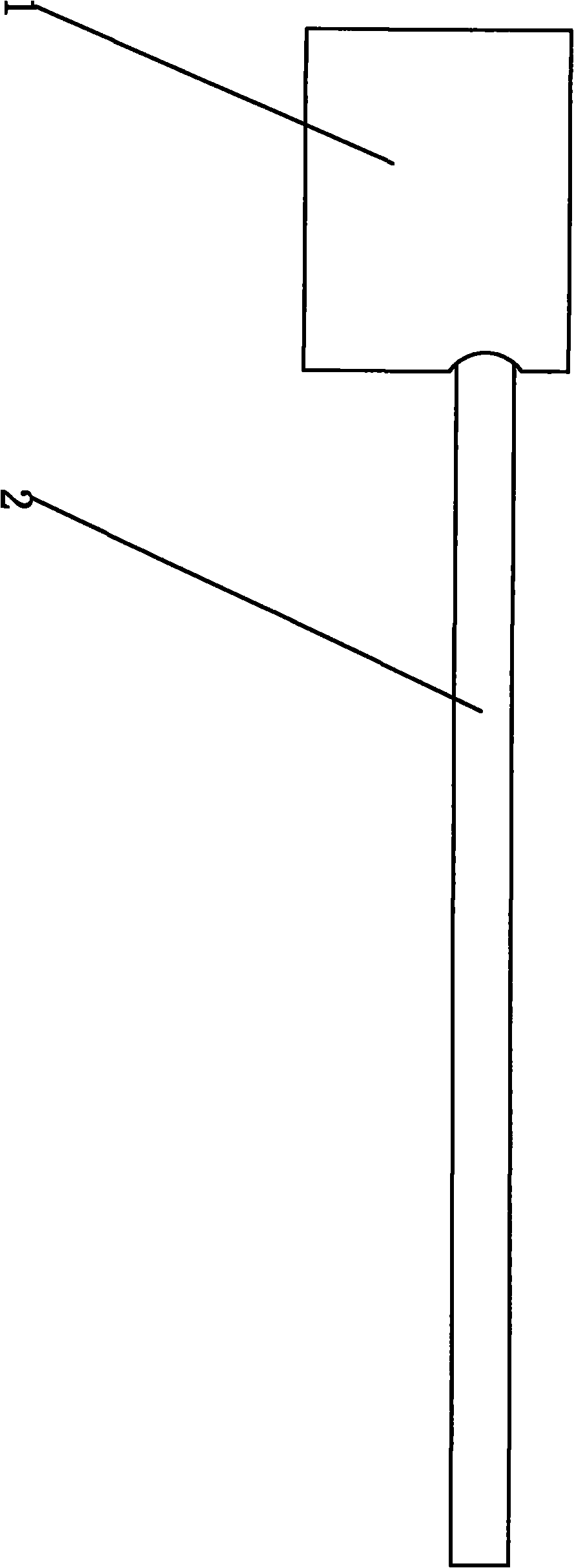

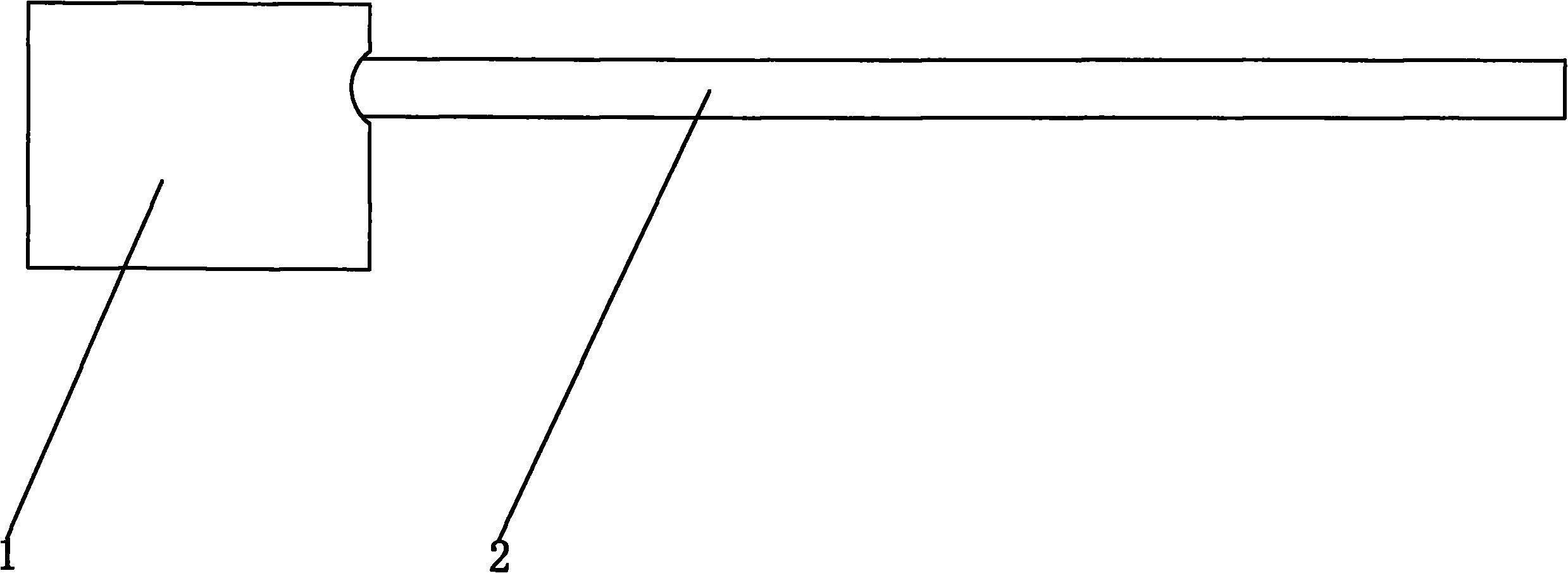

[0029] Reducing and sizing temperature: 920°C

[0030] The billet is heated to 1150°C in the heating furnace and released from the furnace. It is descaled by 20Mpa high-pressure water to remove the oxide scale on the surface of the billet, and is sent to the front of the stretching machine through the conveying roller. Forward movement, the push rod 2 penetrates into the billet, the push rod trolley 1 pushes the push rod 2 to a fixed position in the pass, the feeding roller table rotates, and the billet is fed into the stretching machine. The stretching machine is a three-roll skew rolling mill, and the three rolls are arranged in a circumferential dir...

Embodiment 2

[0032] Outer diameter and wall thickness: φ500mm*120mm hollow continuous casting slab

[0033] Blank length: 8000mm

[0034] Billet weight: 8935kg

[0035] Finished product specification: 114mm*8.5mm

[0036] Finished product length: 12m*33.8=406m

[0037] Baking temperature: 1200°C

[0038] Start rolling temperature: 1150℃

[0039] Reducing and sizing temperature: 920°C

[0040] The billet is heated to 1200°C in the heating furnace and released from the furnace. After descaling with 20Mpa high-pressure water, the iron oxide scale on the surface of the tube billet is removed, and it is sent to the front of the stretching machine through the conveying roller. Forward movement, the push rod 2 penetrates into the billet, the push rod trolley 1 pushes the push rod 2 to a fixed position in the pass, the feeding roller table rotates, and the billet is fed into the stretching machine. The stretching machine is a three-roll skew rolling mill, and the three rolls are arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com