Direct writing method for in situ reduction metal nano-structure

A metal nanostructure and in-situ technology, which is applied in the field of in-situ reduction of metal nanostructures and direct writing of in-situ reduction of metal nanostructures, can solve the problems of high cost, low efficiency, and few types of materials, and achieve high repeatable manufacturing accuracy , simple process and high manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

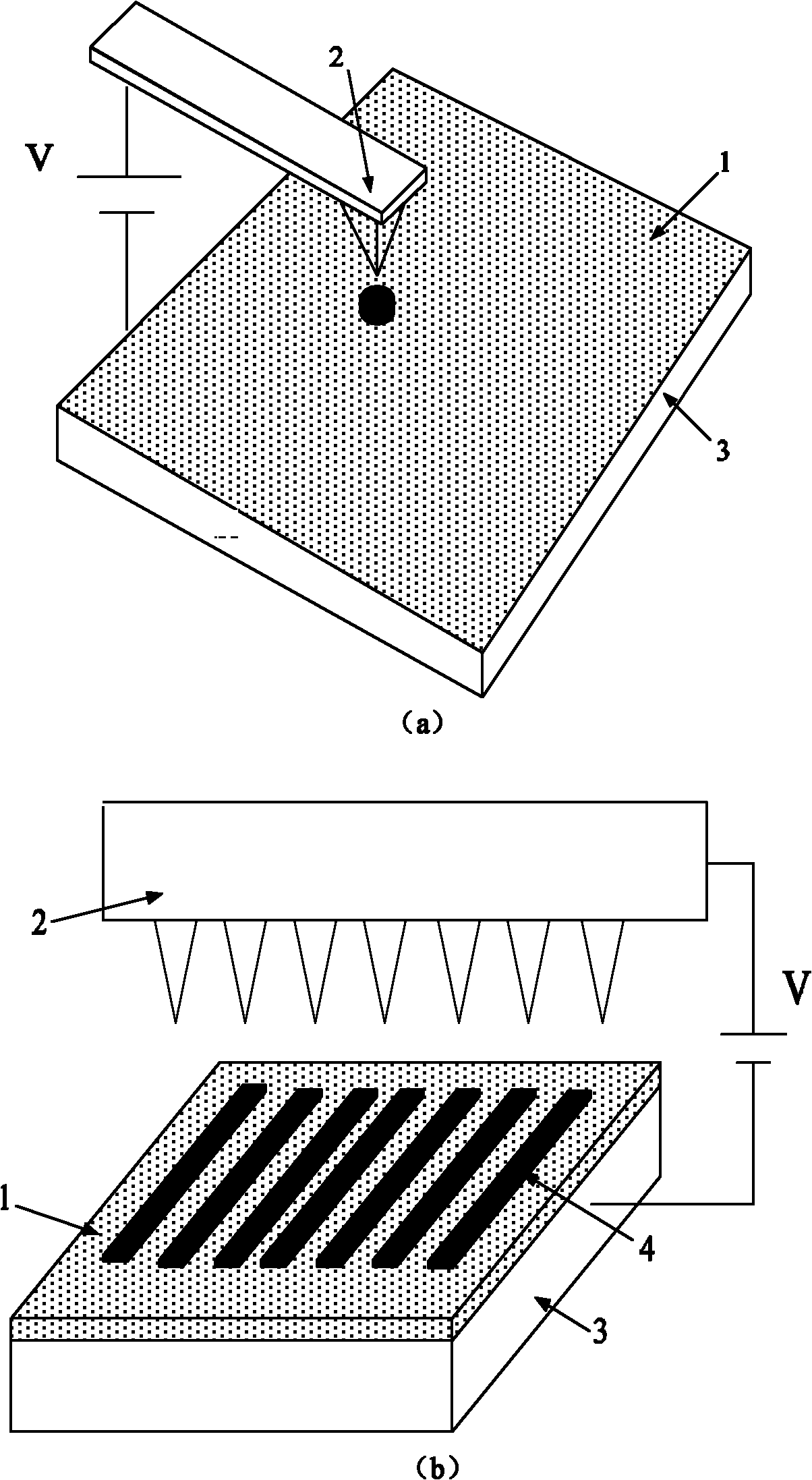

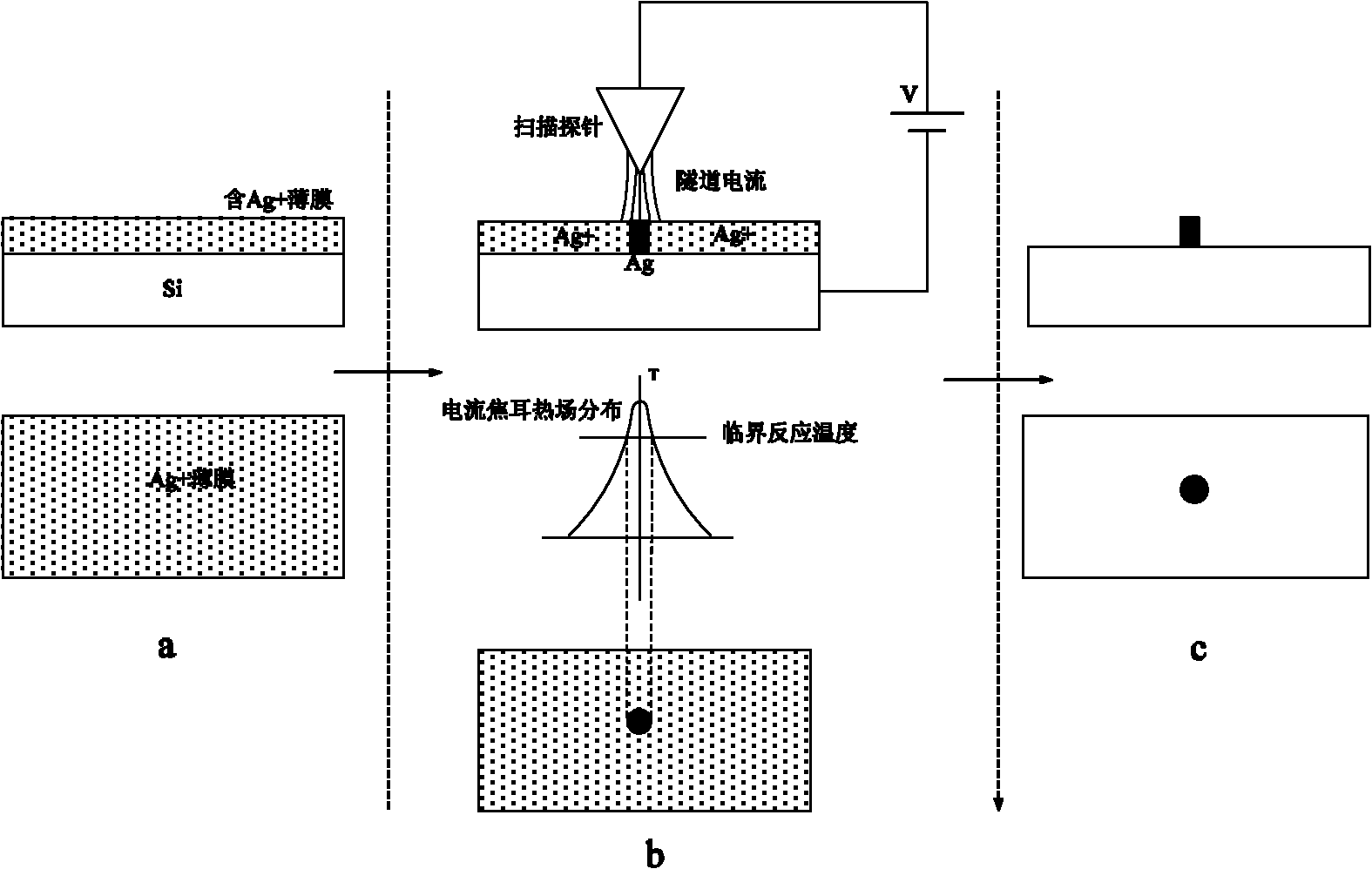

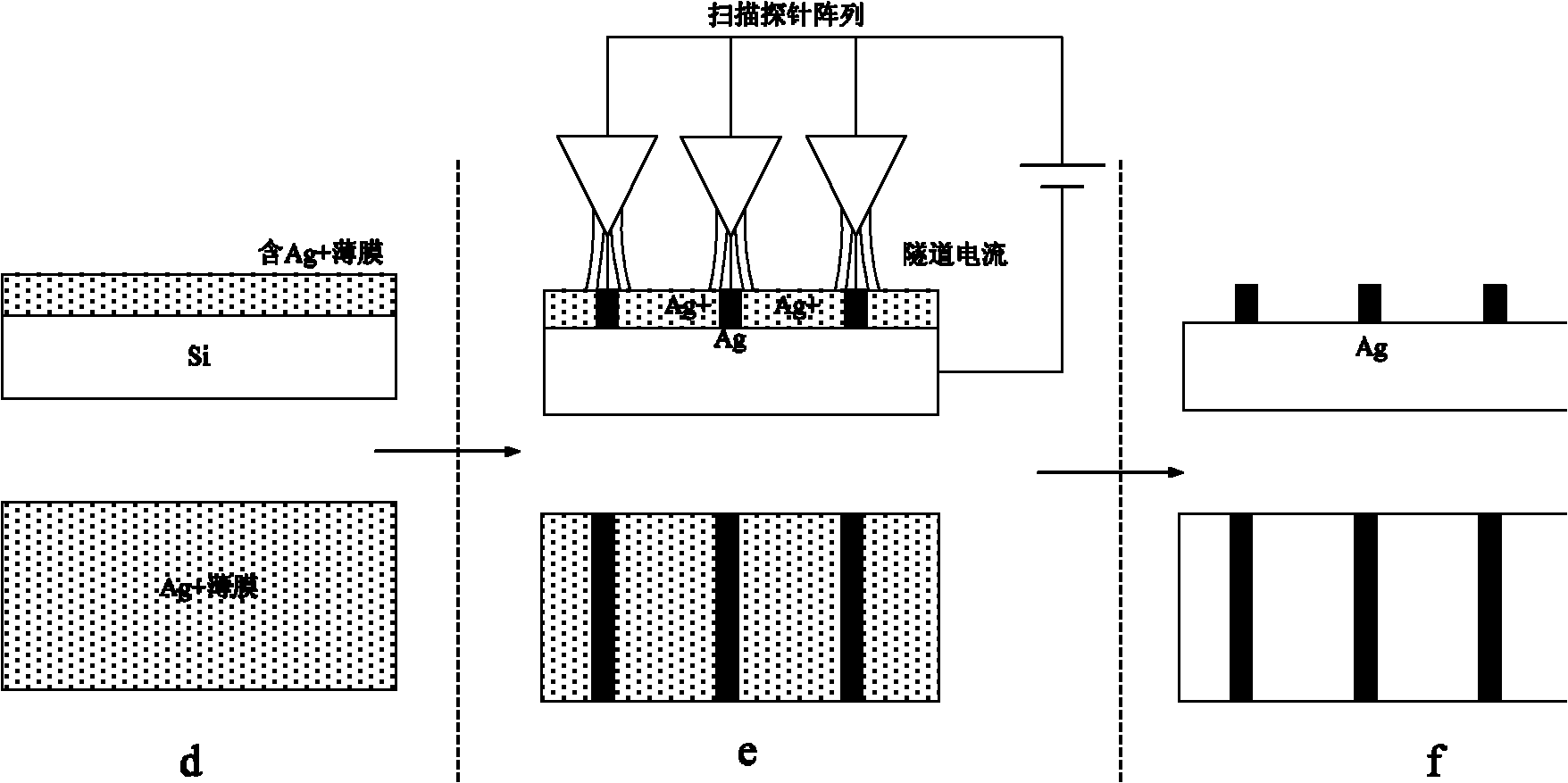

[0019] Example 2: AgNO with a mass ratio of 85:11 3 and CH 3 CHO was dissolved in ammonia water to make a mixed solution with a concentration of 252g / L, and a quartz plate was selected as the base material 3, and the prepared AgNO 3 with CH 3 The ammonia solution of CHO is coated on the surface of the substrate to form a mixed solution film 1 with a thickness of 200nm; the scanning voltage of the STM scanning tunneling microscope is 10V, the electric pulse frequency is 100Hz, and the speed of the scanning probe 2 is 80nm / s.

Embodiment 3

[0020] Example 3: AgNO with a mass ratio of 85:11 3 and CH 3 CHO was dissolved in ammonia water to make a mixed solution with a concentration of 252g / L, and a quartz plate was selected as the base material 3, and the prepared AgNO 3 with CH 3 The ammonia solution of CHO is coated on the surface of the substrate to form a mixed solution film 1 with a thickness of 500nm; the scanning voltage of the STM scanning tunneling microscope is 30V, the electric pulse frequency is 500Hz, and the speed of the scanning probe 2 is 50nm / s.

Embodiment 4

[0021] Example 4: AgNO with a mass ratio of 85:11 3 and CH 3 CHO was dissolved in ammonia water to make a mixed solution with a concentration of 252g / L, and a quartz plate was selected as the base material 3, and the prepared AgNO 3 with CH 3 The ammonia solution of CHO is coated on the substrate surface to form a mixed solution film 1 with a thickness of 800nm; the scanning voltage of the STM scanning tunneling microscope is 40V, the electric pulse frequency is 1000Hz, and the scanning probe 2 speed is 0nm / s (that is, its standing still), forming point-like nanostructures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com