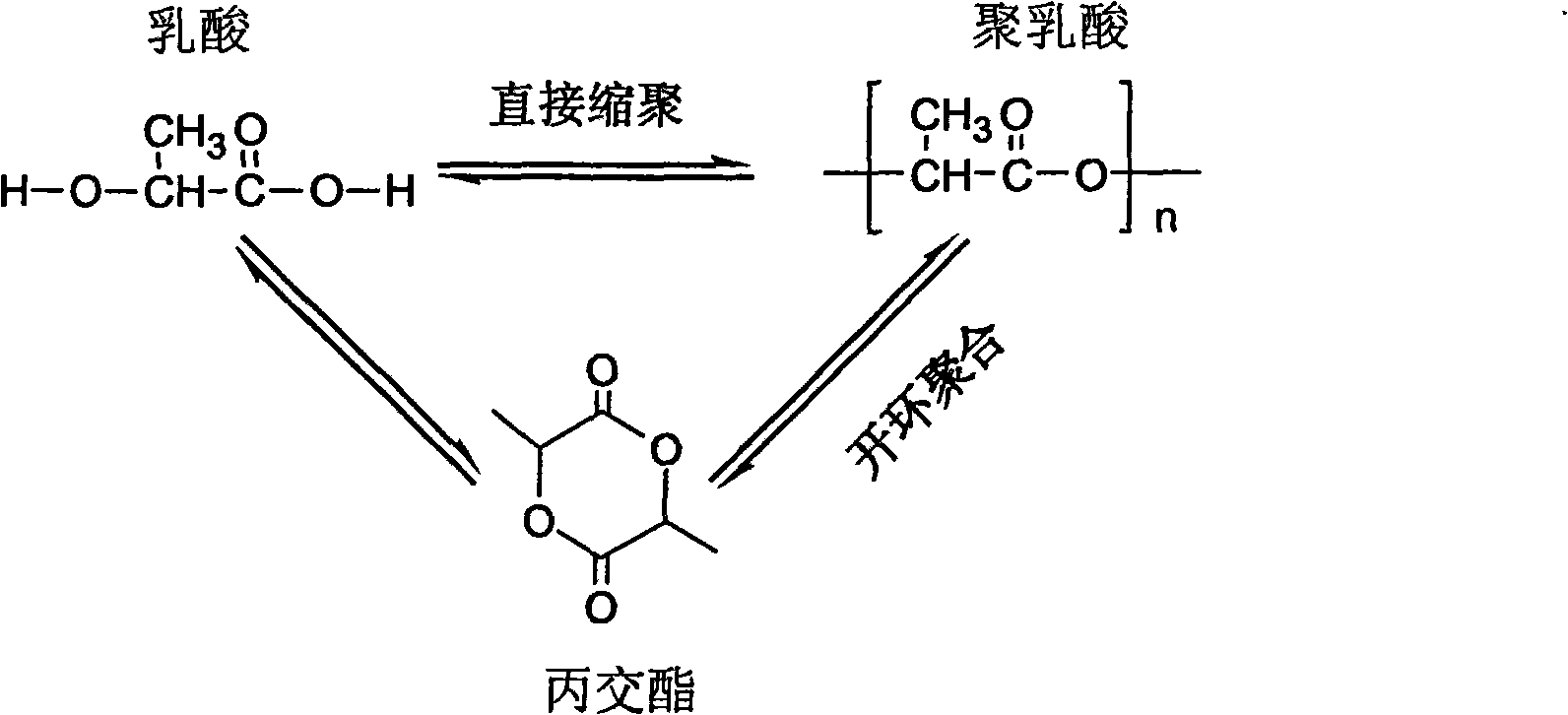

Polylactic acid composition containing sulfoacid compound and phosphorus-containing organic compound and preparation method thereof

A technology of sulfonic acid compound and organic compound, applied in the field of polylactic acid composition and preparation thereof, can solve the problems of poor heat resistance and hydrolysis resistance of polylactic acid, and high production cost of polylactic acid, and achieve the effect of good hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

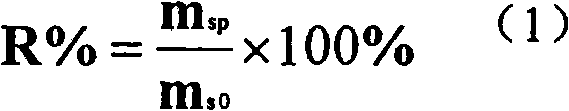

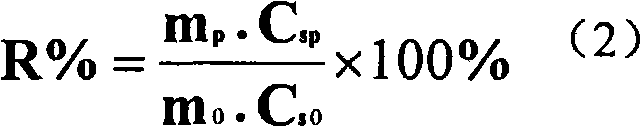

Embodiment 1

[0123] After pouring 200 g of 90 wt % L-lactic acid aqueous solution into a 500 mL four-necked flask, the flask was placed in an oil bath. Install a stirrer on the four-neck flask, insert a thermocouple thermometer, connect the vacuum pipeline and the nitrogen pipeline and replace with nitrogen for 3 times, then raise the temperature of the oil bath to 120°C for dehydration. The system pressure gradually decreased from normal pressure to 5KPa within 60 minutes from the start of dehydration; then continued dehydration at 5KPa for 1.5 hours (total dehydration 2.5 hours); at this time, after returning the system pressure to normal pressure with nitrogen, add 1,3-propanedisulfonic acid 8.61mg (the addition amount is 15ppm relative to the monomer mass in terms of sulfur element, that is, C s0 =15ppm, the same below). Then the temperature of the system was raised to 150°C, the pressure was gradually reduced from normal pressure to 0.2KPa within 2 hours and the pressure was kept at ...

Embodiment 2

[0133] After pouring 200 g of 90 wt % L-lactic acid aqueous solution into a 500 mL four-necked flask, the flask was placed in an oil bath. Install a stirrer on the four-neck flask, insert a thermocouple thermometer, connect the vacuum pipeline and the nitrogen pipeline and replace with nitrogen for 3 times, then raise the temperature of the oil bath to 120°C for dehydration. The system pressure gradually decreased from normal pressure to 5KPa within 60 minutes from the start of dehydration; then continued dehydration at 5KPa for 1.5 hours (total dehydration 2.5 hours); at this time, after returning the system pressure to normal pressure with nitrogen, add 1,20-eicosanedisulfonic acid 7719.8mg (6210ppm). Then the temperature of the system was raised to 160°C, the pressure was gradually reduced from normal pressure to 0.3KPa within 2 hours, and the pressure was kept at 0.3KPa for 4 hours (6 hours in total) after melt polymerization, poured out, and cooled to obtain polylactic ac...

Embodiment 3

[0143] After pouring 200 g of 90 wt % L-lactic acid aqueous solution into a 500 mL four-necked flask, the flask was placed in an oil bath. Install a stirrer on the four-neck flask, insert a thermocouple thermometer, connect the vacuum pipeline and the nitrogen pipeline and replace with nitrogen for 3 times, then raise the temperature of the oil bath to 120°C for dehydration. The system pressure gradually decreased from normal pressure to 5KPa within 60 minutes from the start of dehydration; then continued dehydration at 5KPa for 1.5 hours (total dehydration 2.5 hours); at this time, after returning the system pressure to normal pressure with nitrogen, add 1,3-propanedisulfonic acid 240.75mg (C s0= 420ppm). Then the temperature of the system was raised to 160°C, the pressure was gradually reduced from normal pressure to 0.3KPa within 2 hours and the pressure was kept at 0.3KPa after melt polymerization for 4 hours (6 hours in total) and then cooled to obtain a polylactic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com