Energy-saving fuel oil composition

A composition and fuel oil technology, applied in the field of fuel oil, can solve the problems of difficult emulsification of fuel oil, and achieve the effects of small colloidal particle size, high combustion efficiency and considerable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

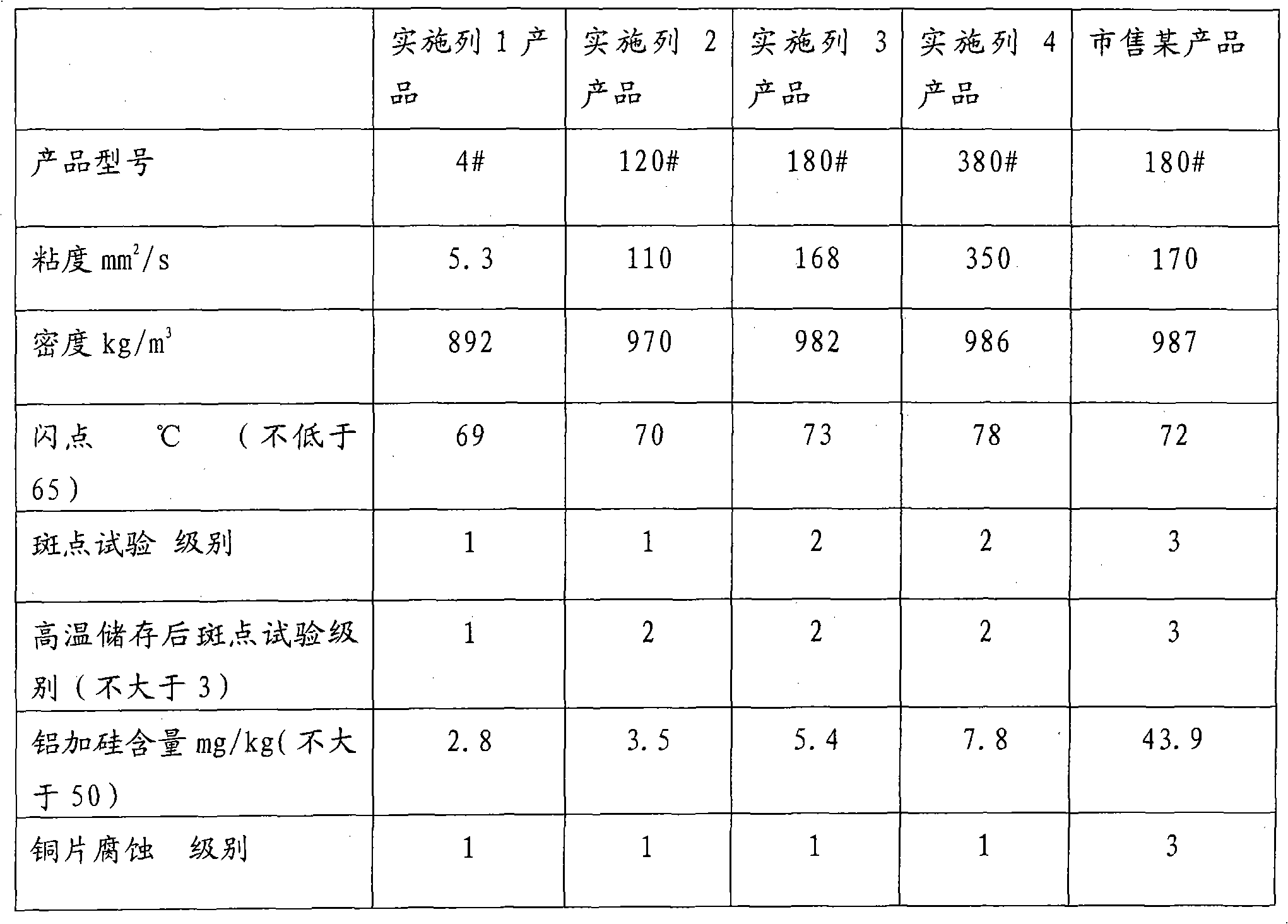

example 1

[0015] Take 5 parts of heavy residue oil by-product of petroleum, its viscosity at 100℃ is 500mm 2 / s; 93.9 parts of shale oil with a viscosity of 5mm at 50°C 2 / s; The amount of emulsifier Sparene-80 is 1 part, the coupling agent ethanol is 0.1 part, and the metal deactivator T1201 is 1×10 -6 The fuel oil is obtained by adding it to the blending tank at 55-65°C and fully stirring for 10-14 hours to filter out impurities. The finished fuel oil obtained meets the 4# fuel oil index.

example 2

[0017] Take 30 parts of heavy residue oil by-product of petroleum, its viscosity at 100℃ is 800mm 2 / s; 66.5 parts of shale oil with a viscosity of 11mm at 50°C 2 / s; The emulsifier uses alkylphenol polyoxyethylene ether NP-4, the dosage is 3 parts, the coupling agent uses glycerol 0.5 parts, and the metal deactivator T1201 is 2×10 -6 The fuel oil is obtained by adding it to the blending tank at 55-65°C and fully stirring for 10-14 hours to filter out impurities. The finished fuel oil obtained meets the 120# fuel oil index.

example 3

[0019] Take 50 parts of heavy residue oil by-product, and its viscosity at 100°C is 1200mm 2 / s; 46 parts of low temperature coal tar, its viscosity at 50°C is 18mm 2 / s; the amount of emulsifier Benzene-80 is 1 part, the amount of emulsifier alkylphenol polyoxyethylene ether NP-4 is 1 part; the coupling agent butanol is 2 parts, the metal deactivator T1201 is 5×10 -6 The fuel oil is obtained by adding it to the blending tank at 55-65°C and fully stirring for 10-14 hours to filter out impurities. The finished fuel oil obtained meets the 180# fuel oil index.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com