Solid calcium metal cored wire for deoxidation in steel making

A technology of metal calcium and cored wire, applied in the field of metallurgy, can solve the problems of not very ideal, waste of metal calcium, affecting the performance of steel, etc., and achieve the effects of increasing the absorption time, reducing the temperature drop in the process, and reducing the gasification speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

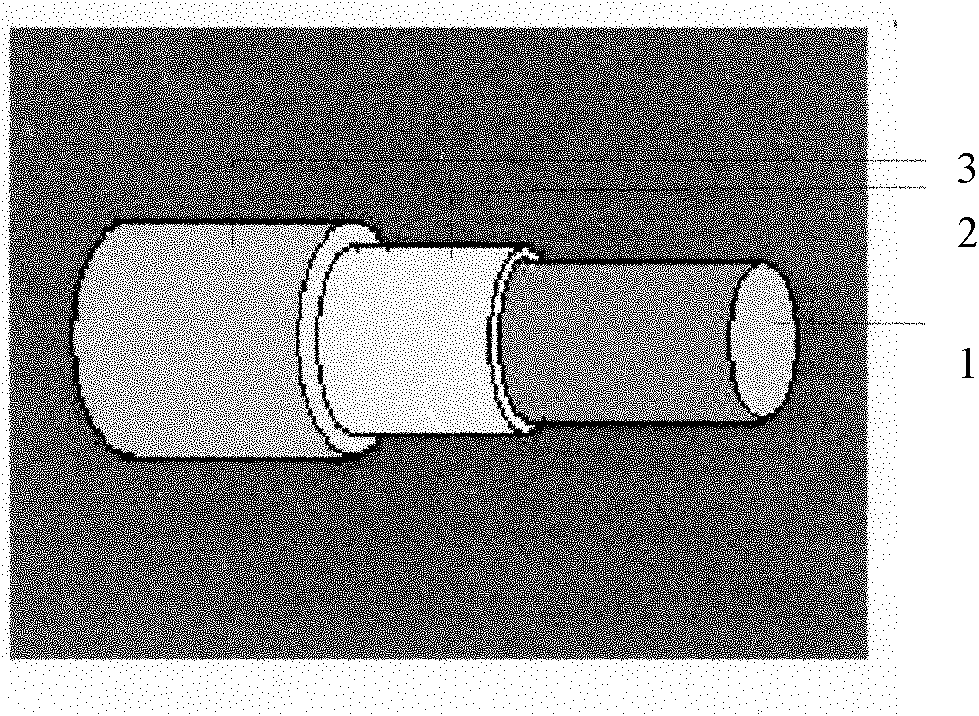

[0031] The solid metal calcium cored wire used for steelmaking deoxidation of the present invention is composed of an outer layer 3 wrapping an intermediate layer 2, and the intermediate layer 2 wrapping an inner core 1, and the inner core 1 is composed of the sum of the weight of impurities not higher than 0.1wt %, the density is 1.51-1.54g / cm 3 The solid metal calcium wire; the middle layer 2 is machine oil or rapeseed oil; the outer layer 3 is A3 steel or Q195 steel. The thickness of the A3 steel or Q195 steel is 0.56mm. The diameter of the inner core is 7.5-8mm.

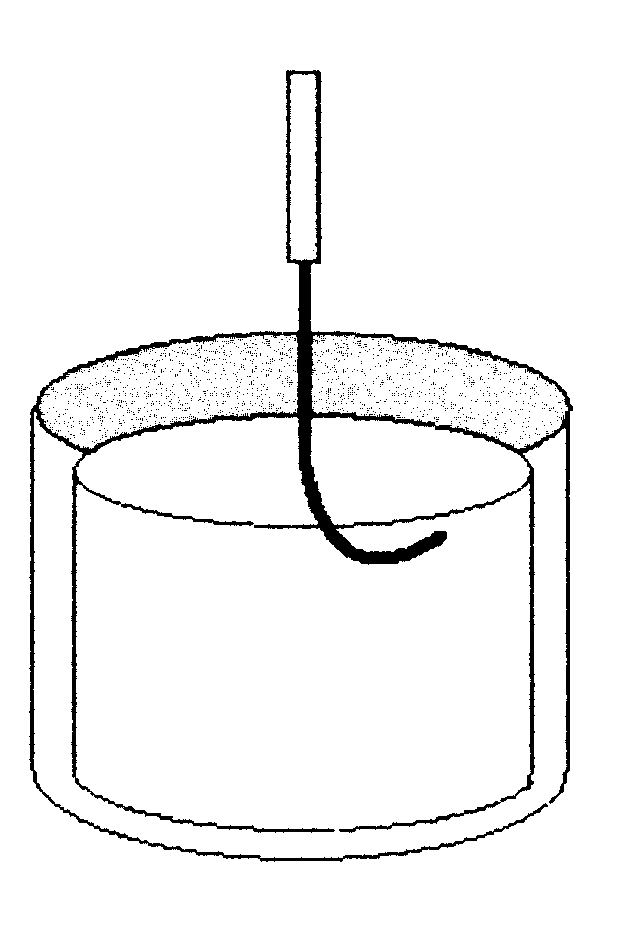

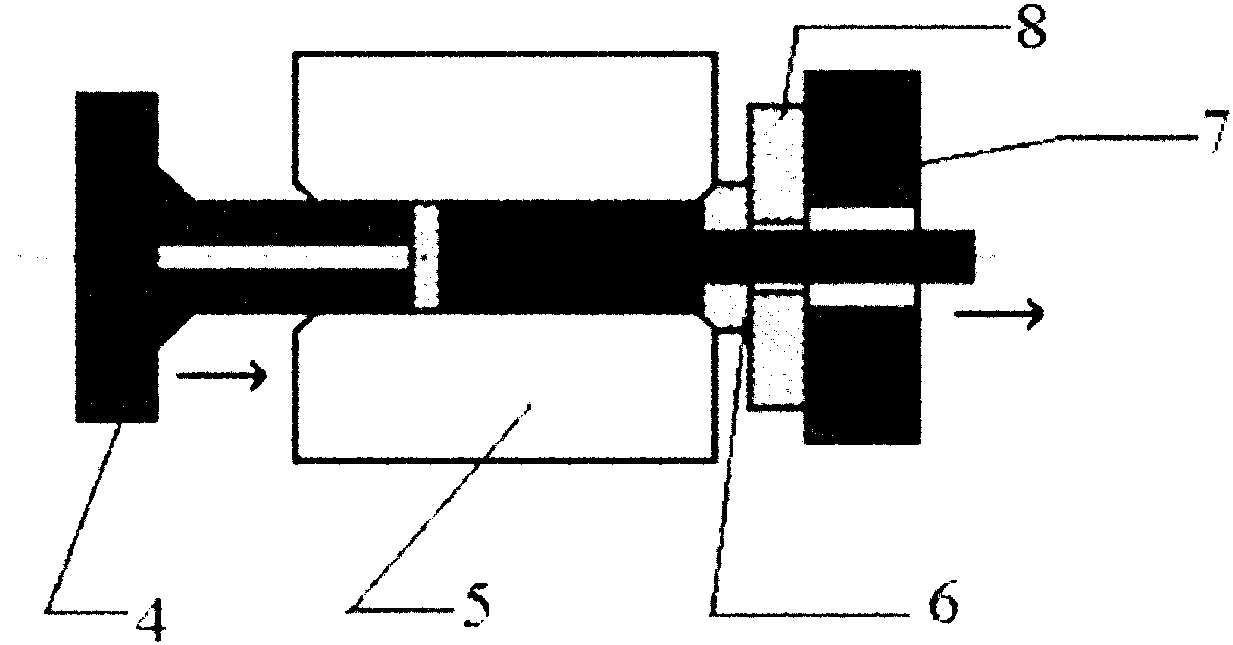

[0032] The present invention prepares the extrusion equipment that the inner core of solid metal calcium wire adopts such as image 3 shown. Its workflow for preparing solid calcium metal wires, such as Figure 4 shown. Mainly, the calcium ingot is first heated to 400°C in a gas-protected furnace, and then placed in a primary extruder to extrude by applying pressure through the extrusion rod, and then cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com