Ship selective catalytic reduction emission-reducing system

A selective, marine technology, applied in molecular sieve catalysts, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Advanced problems, to achieve the effect of good work performance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

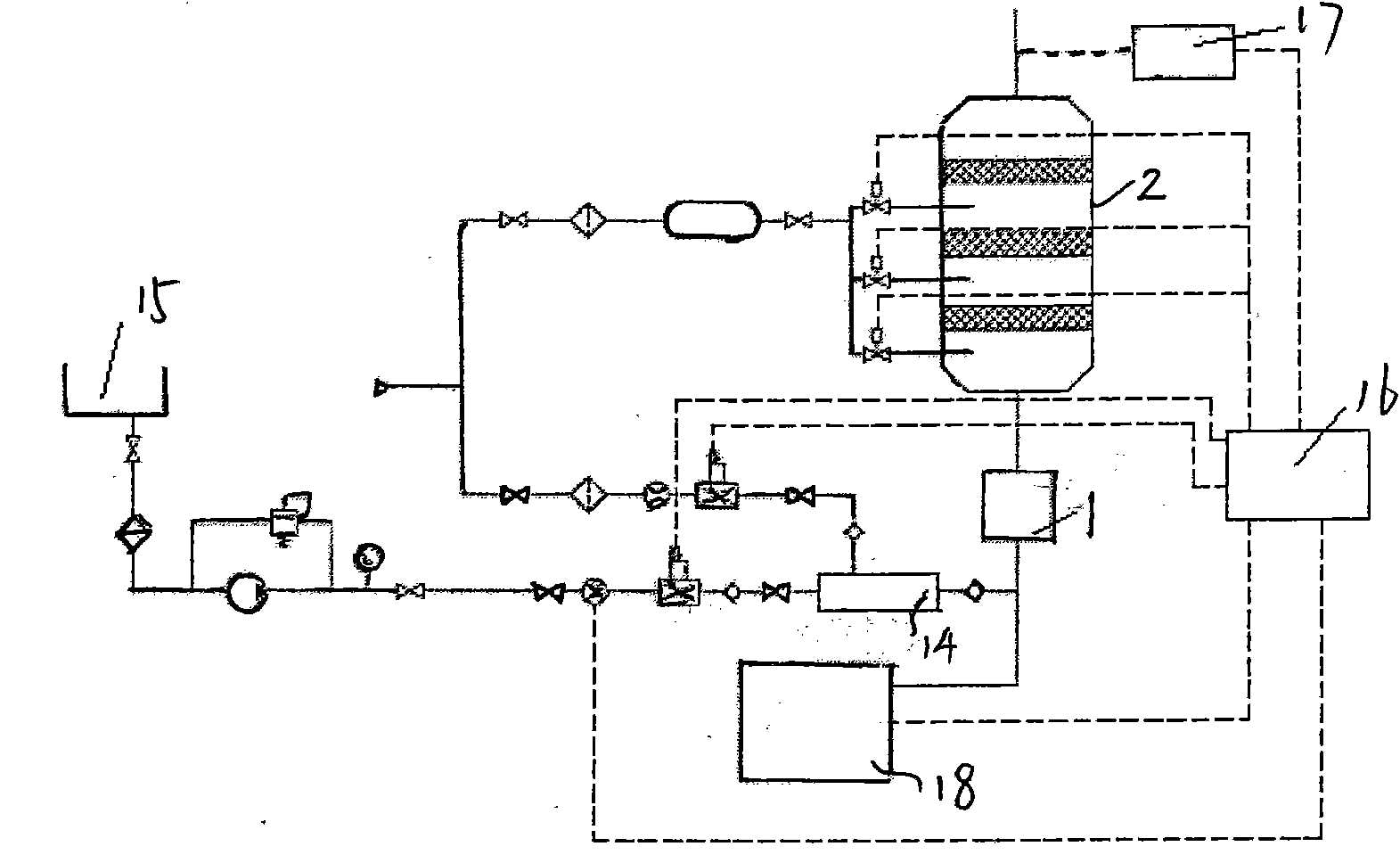

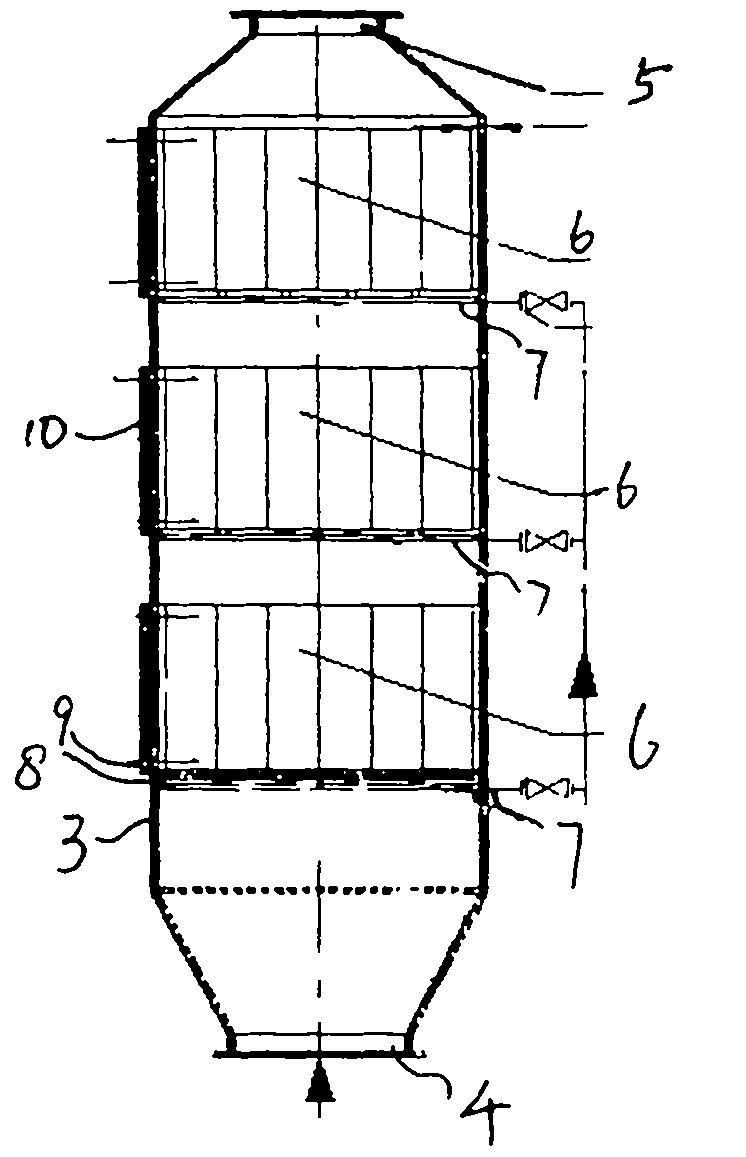

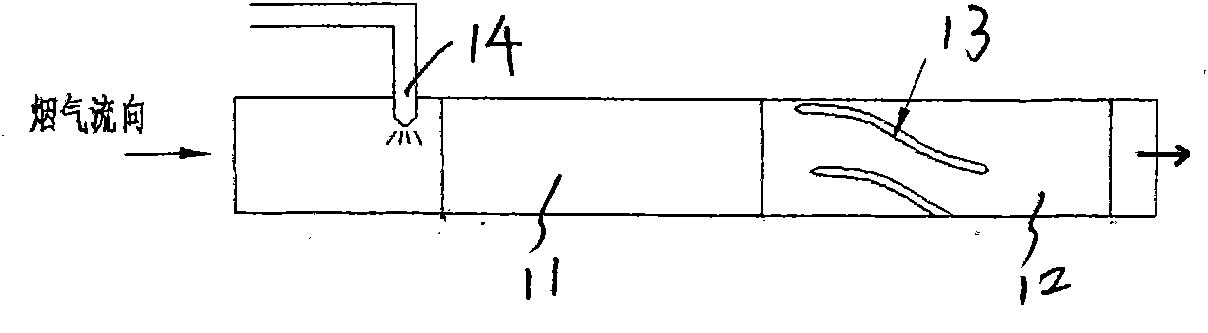

[0042] A marine selective catalytic reduction emission reduction system, including a mixer 1 for mixing a reducing agent with engine flue gas, the mixer is connected to the flue gas inlet of a reactor 2; the reactor includes a shell 3, and a flue gas inlet is arranged on the shell 4. The purified gas outlet 5, and the catalyst module 6 is arranged in the casing; the reducing agent is an aqueous urea solution. The mass concentration of urea in the urea aqueous solution is 39.5-40.5%.

[0043] For a four-stroke supercharged intercooled diesel engine with a speed of 600-1200r / min, the flue gas produced by fuel with a sulfur content of 2 o 5 -TiO 2 , where V 2 o 5 :TiO 2 The mass ratio is: V 2 o 5 :TiO 2 =1:90; For four-stroke supercharged intercooled diesel engines with a rotational speed of 600-1200r / min, the flue gas produced by fuel with a sulfur content greater than 1.5%, and when the temperature of the flue gas is 280-420°C, the catalyst shall be vulcanized Cobalt ox...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap