Chitosan/ synthetic hydrotalcite composite permeable membrane, preparation method and application thereof

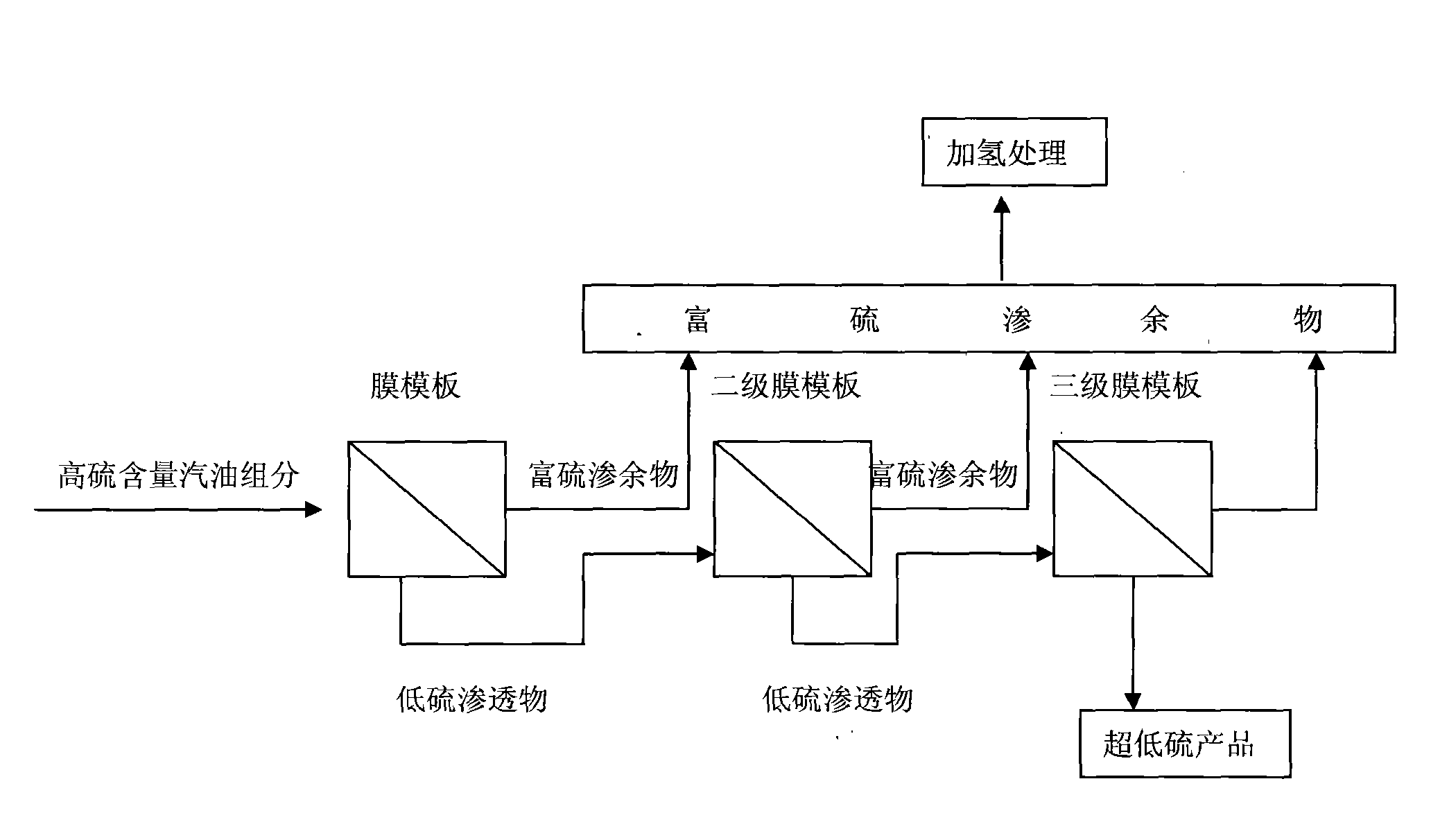

A technology of hydrotalcite and chitosan, which is applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of unsatisfactory desulfurization effect and low removal effect of thiophene organic sulfur-containing compounds, etc. Mechanical strength, large specific surface area, the effect of prolonging the life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1. hydrotalcite-like preparation

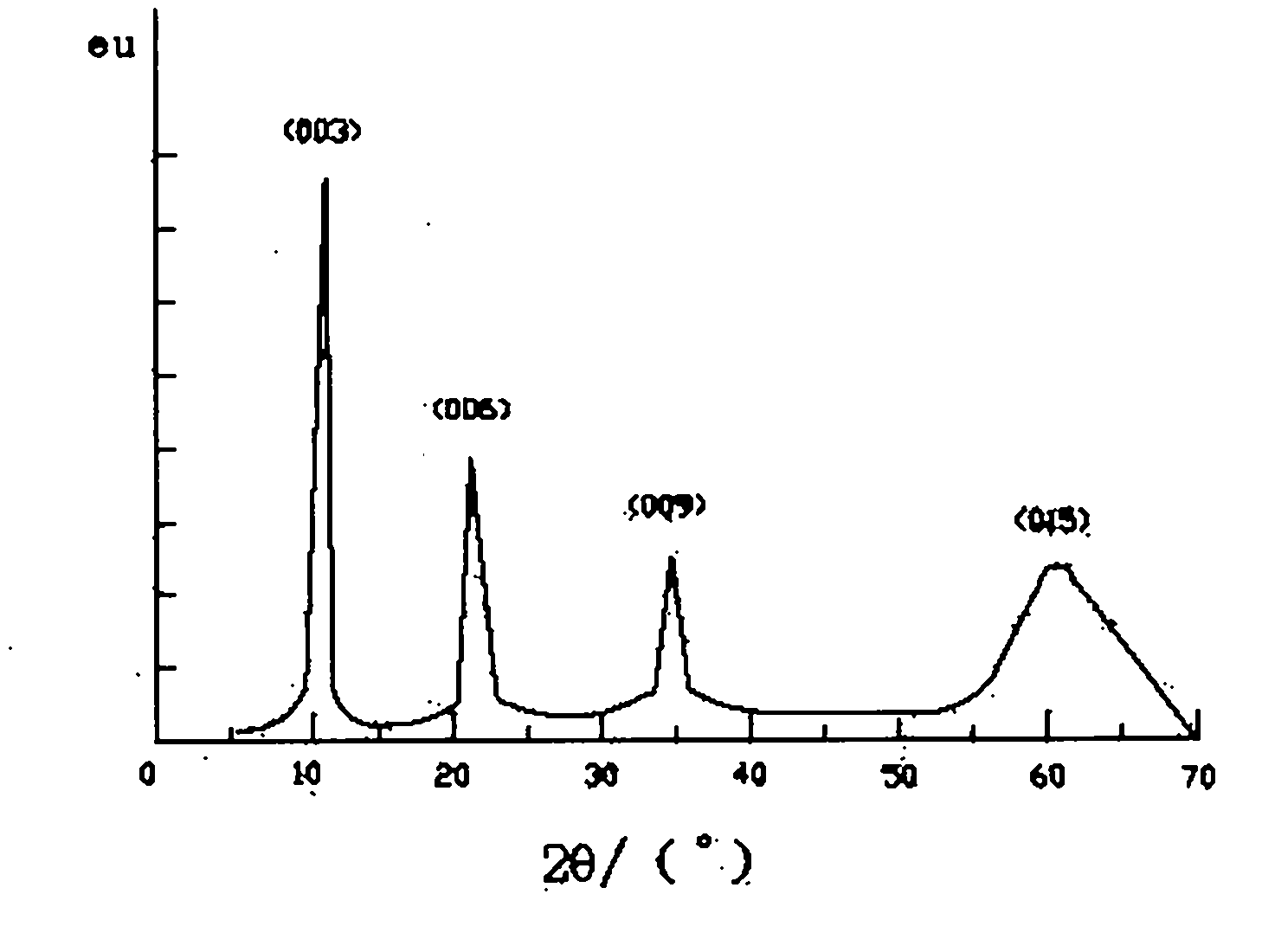

[0061] MgCl 2 ·6H 2 O, AlCl 3 ·6H 2 O and FeCl 3 ·6H 2 O was formulated into a mixed solution at a molar ratio of 0.8:3:1, and coprecipitant ammonia water was added under continuous stirring to adjust the pH value of the solution to 9.8, and coprecipitation was formed. Aging for 1.5 hours, filtering and washing; sealing the filter cake in a glass container, keeping the temperature between 72-80°C and peptizing for 12 hours to obtain Fe 0.87 Mg 2.60 (Al(OH) 10.2 Cl 0.6 ) layered hydrofossil compounds. The particle size measurement shows that the average particle size is 201.9nm, the average thickness of layered crystals is 35nm, the interlayer distance is 0.76nm, the interlayer channel height is 0.50nm, and the specific surface area is 1820m 2 / g, zero charge point 10.35, isoelectric point 11.23. X-ray analysis proves that it has a hydrotalcite-like crystal structure: its characteristic diffraction angles 2θ are 10...

Embodiment 2

[0063] Hydrotalcite-like preparation

[0064] MgCl 2 ·6H 2 O, AlCl 3 ·6H 2 O and FeCl 3 ·6H 2 O is formulated into a mixed solution at a molar ratio of 0.6: 1: 3, and the coprecipitant ammonia water is added under constant stirring to adjust the pH value of the solution to 10, coprecipitation is generated, aged for 1.5 hours, filtered and washed; the filter cake is sealed in In a glass container, keep the temperature between 72-80°C and peptize for 12 hours to obtain Fe 0.62 Mg 2.70 (Al(OH) 10.3 Cl 0.7 ) layered hydrofossil compounds. Particle size analysis shows that the average particle size is 121nm, the average thickness of layered crystals is 40nm, the interlayer distance is 0.8nm, the interlayer channel height is 0.7nm, and the specific surface area is 1520m 2 / g, zero charge point 11.25, isoelectric point 12.1. X-ray analysis demonstrated a hydrotalcite-like crystal structure: the positions of the peaks did not change.

Embodiment 3

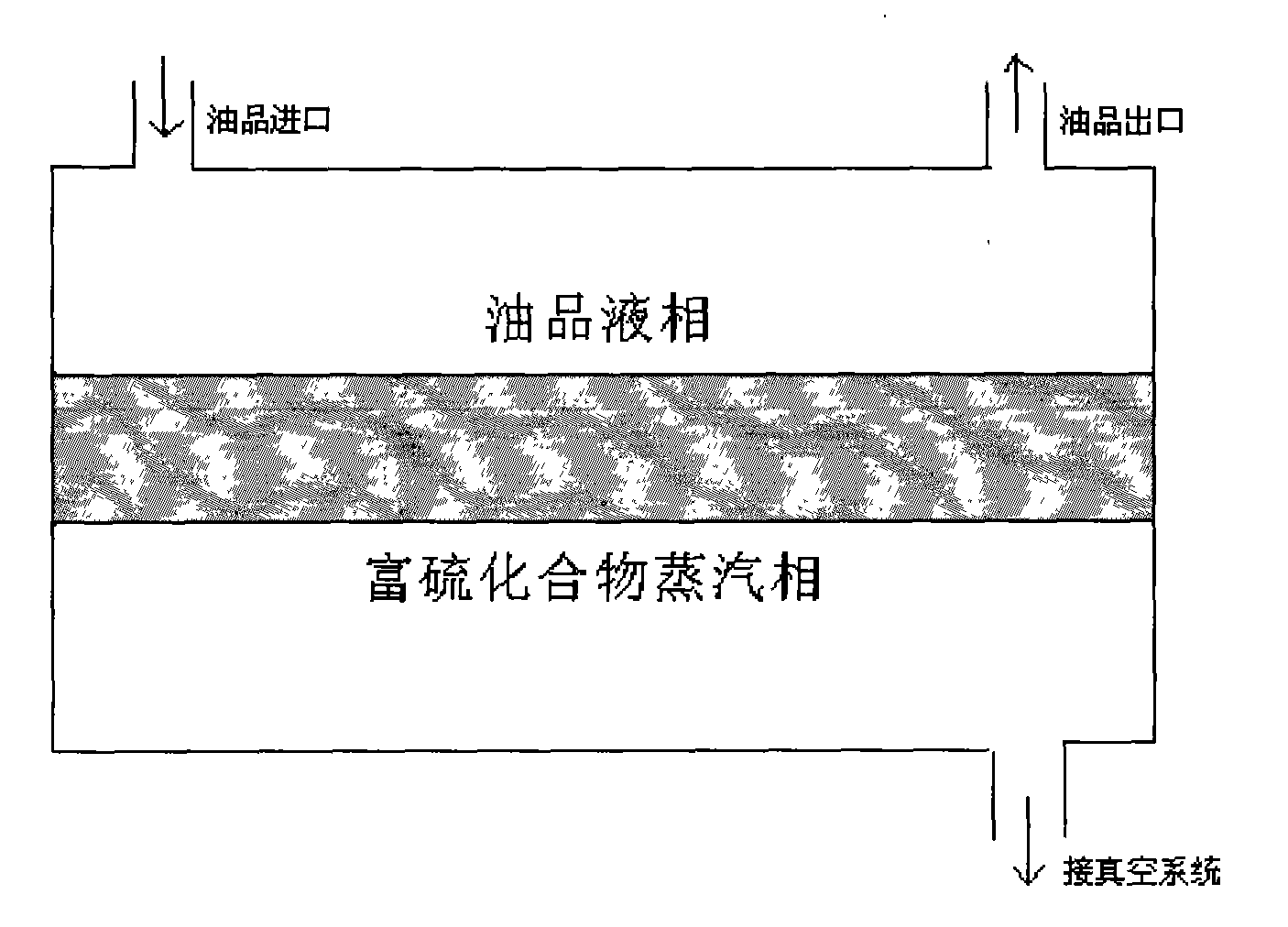

[0065] Embodiment 3. Composite permeable membrane preparation

[0066] It is 75% that the degree of deacetylation of 2g, the chitosan that molecular weight is 15000 are dissolved in the 3wt% acetic acid aqueous solution of 100ml, add the hydrotalcite-like fine powder that 80g embodiment 1 synthesizes under constant stirring and stir 2 hours; Add 0.8ml of 25wt% succinaldehyde solution to make the chitosan undergo cross-linking reaction to obtain a synthetic hydrotalcite-like suspension that absorbs the cross-linked chitosan film.

[0067] A 15% cellulose acetate solution was coated on the surface of a glass plate and dried at 100°C to obtain a 25 μm support film. Then the prepared chitosan / synthetic hydrotalcite suspension was spin-coated (i.e., spin-coated) on a cellulose acetate support film, and dried at 60°C to obtain a total film thickness of 55 μm, and then obtained from a glass substrate Peeling off on the surface is the product of the pervaporation separation membrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com