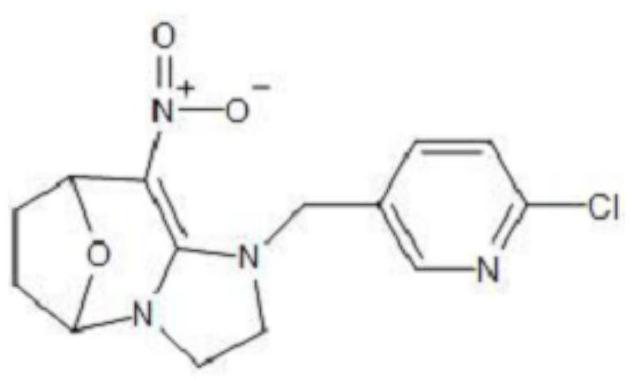

Preparation method of cycloxaprid

A technology of cyclofenapyr and sodium hydroxide, applied in the direction of organic chemistry and the like, can solve problems such as low purity of cyclofenapyr, and achieve the effects of good application prospect and economic benefit, safe preparation method and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the examples. The technical schemes and related parameters given in the following embodiments are only exemplary, and are intended to explain the present invention, but should not be construed as limiting the present invention.

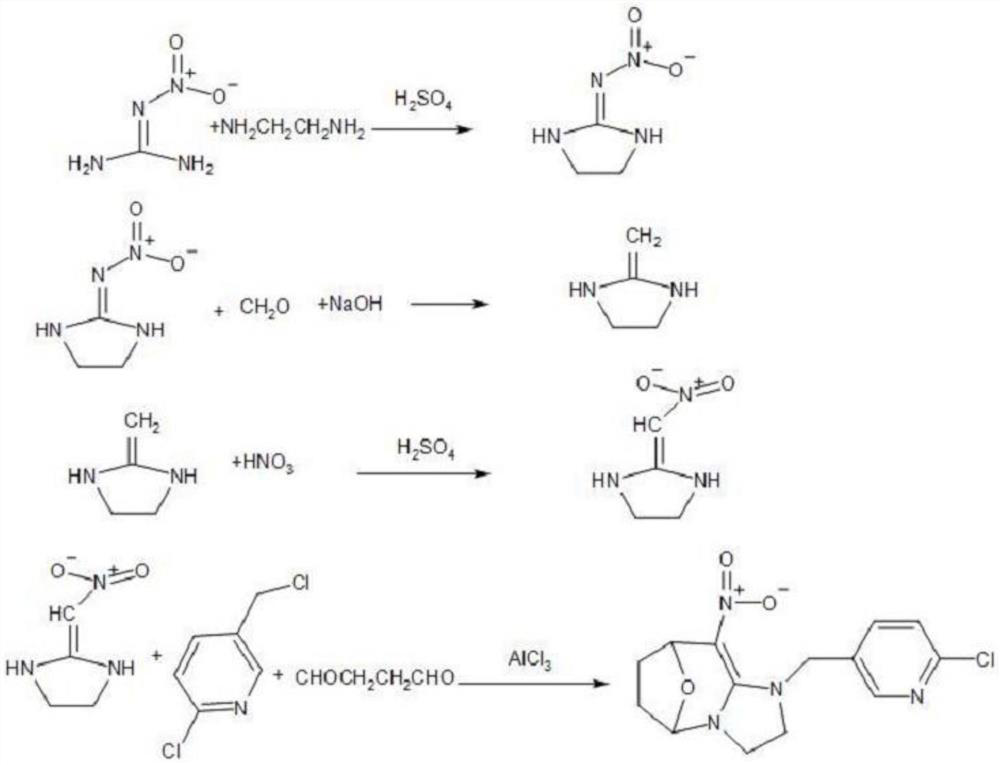

[0021] This embodiment discloses a preparation method of cyclopyridam, in which the addition process of each component is carried out by dropping, and the specific steps are as follows:

[0022] 1) Add 100g of clear water, 70g of nitroguanidine with a water content of 25%, and 24.5g of concentrated sulfuric acid into a 500ml round-bottomed flask. After stirring evenly, add 33g of ethylenediamine dropwise, heat up to 70°C, keep warm for 1h, and cool down after the reaction is completed. Filtrating, washing, collecting and drying the filter cake to obtain 2-nitroiminoimidazolidine, and the filtrate is concentrated and used mechanically;

[0023] 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com