Method for treatment of wastewater containing heavy metal molybdenum

A treatment method and heavy metal technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effect of reducing the content of heavy metal molybdenum, good economic benefits, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

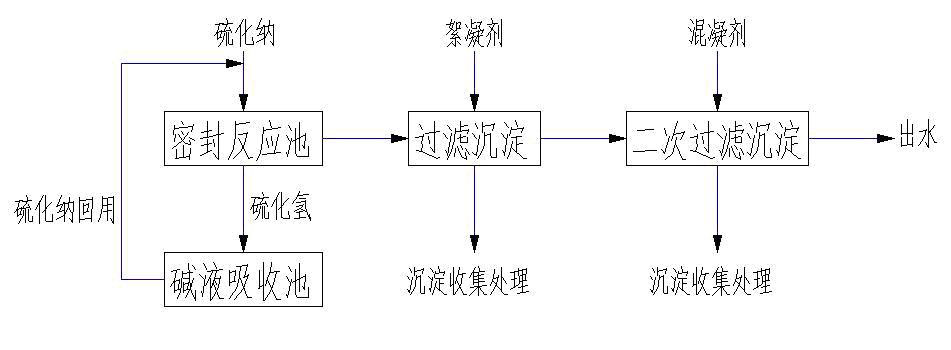

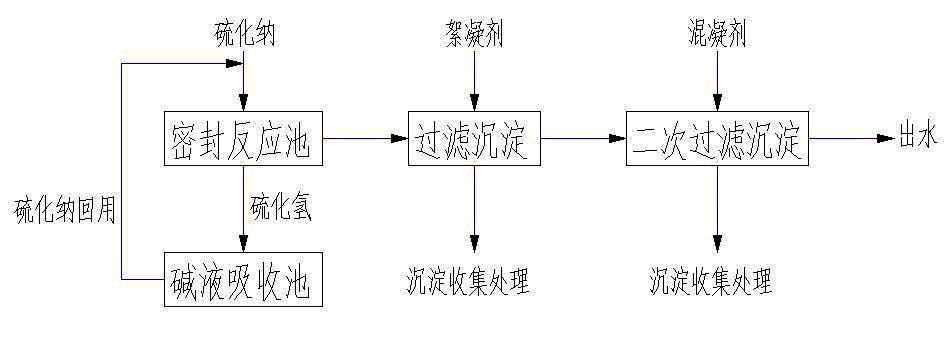

Image

Examples

Embodiment 1

[0021] Prepare a solution containing molybdenum 100 mg / L, add sodium sulfide at a molar ratio of 1:3 between molybdenum and sodium sulfide, adjust the pH value of the solution to 2, react at room temperature for 2 hours, and add flocculant to the resulting solution And stir quickly, let stand for 5 minutes, drain the supernatant on the sediment and filter. Adjust the pH value of the filtered solution to a neutral condition, add a mixed coagulant of polyaluminum chloride and ferrous sulfate and stir rapidly, let stand for 2 minutes, drain the supernatant on the sediment and filter.

Embodiment 2

[0023] Prepare a solution containing 100 mg / L of molybdenum, add sodium sulfide at a molar ratio of 1:3 between molybdenum and sodium sulfide, adjust the pH value of the solution to 2, react at room temperature for 3 hours, and add flocculant to the obtained solution And stir quickly, let stand for 5 minutes, drain the supernatant on the sediment and filter. Adjust the pH value of the filtered solution to a neutral condition, add a mixed coagulant of polyaluminum chloride and ferrous sulfate and stir rapidly, let stand for 2 minutes, drain the supernatant on the sediment and filter.

Embodiment 3

[0025] Prepare a solution containing 100 mg / L of molybdenum, add sodium sulfide at a molar ratio of 1:6 between molybdenum and sodium sulfide, adjust the pH value of the solution to 2, react at room temperature for 2 hours, and add flocculant to the resulting solution And stir quickly, let stand for 5 minutes, drain the supernatant on the sediment and filter. Adjust the pH value of the filtered solution to a neutral condition, add a mixed coagulant of polyaluminum chloride and ferrous sulfate and stir rapidly, let stand for 2 minutes, drain the supernatant on the sediment and filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com