Refrigerating system for preparing supercooled water ice slurry

A refrigeration system and supercooled water technology, applied in ice making, ice making, refrigerators, etc., can solve problems such as unstable liquid supply control, complex separation systems, and subcoolers that reduce refrigeration cycles and efficiency, and improve heat transfer Efficiency and uniformity of heat transfer, simplification of system flow and control system, effect of reducing the risk of clogging the subcooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below through specific examples.

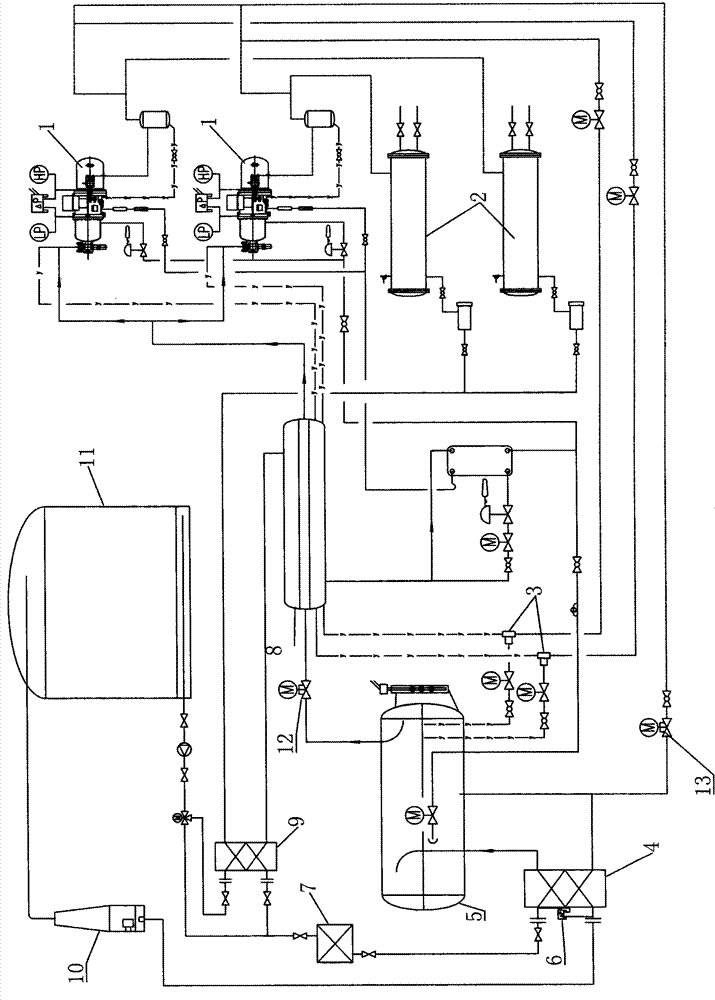

[0016] Such as figure 1 Shown is a refrigeration system for producing supercooled water ice slurry, including a refrigerant circulation system and a water circulation system.

[0017] The water circulation system includes a cold storage tank 11 and a supercooler 4, an ice core filter 7 is installed on the water supply pipeline of the cold storage tank 11 to the supercooler 4, and an ice core filter 7 is installed on the passage for supplying supercooled water to the cold storage tank 11 by the supercooler 4. The supercooling elimination device 10 is also connected in parallel with a bypass valve formed by a preheater 9 and a three-way valve on the water supply line between the cold storage tank 11 and the supercooler 4, which is used to control the inlet water temperature of the subcooler and the For melting and deicing.

[0018] The refrigerant circulation system includes a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com