Projection optical engine

A projection optics and engine technology, applied in optics, optical components, lenses, etc., can solve the problems of single-chip LED light waves not being well matched, increasing the light output of LED projection light sources, and the difficulty of manufacturing color-combining prisms, etc., to achieve Low cost, good color rendition, and the effect of increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A projection optical engine provided by the technical solution will be described below in combination with embodiments.

[0042] The present invention is implemented like this:

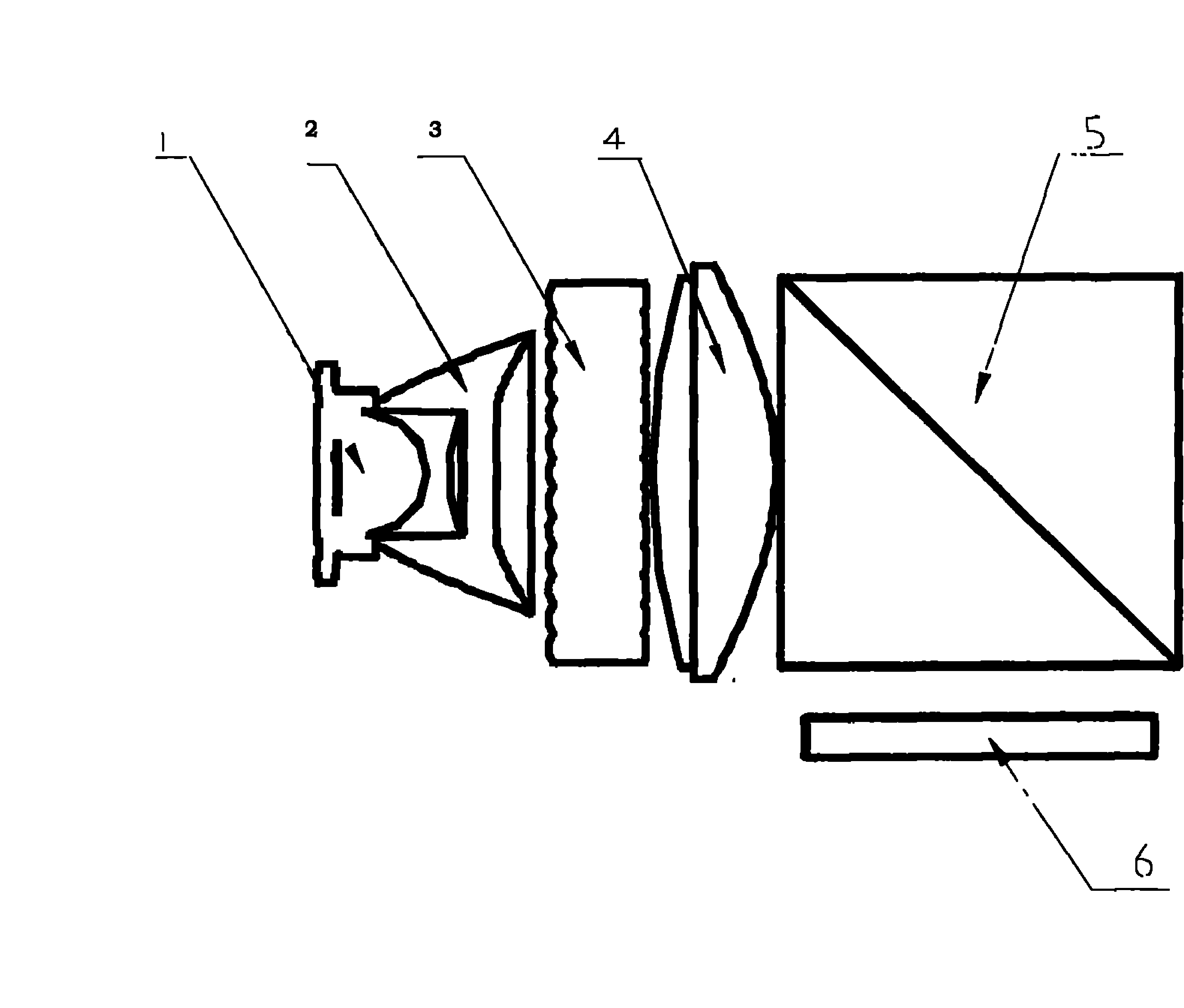

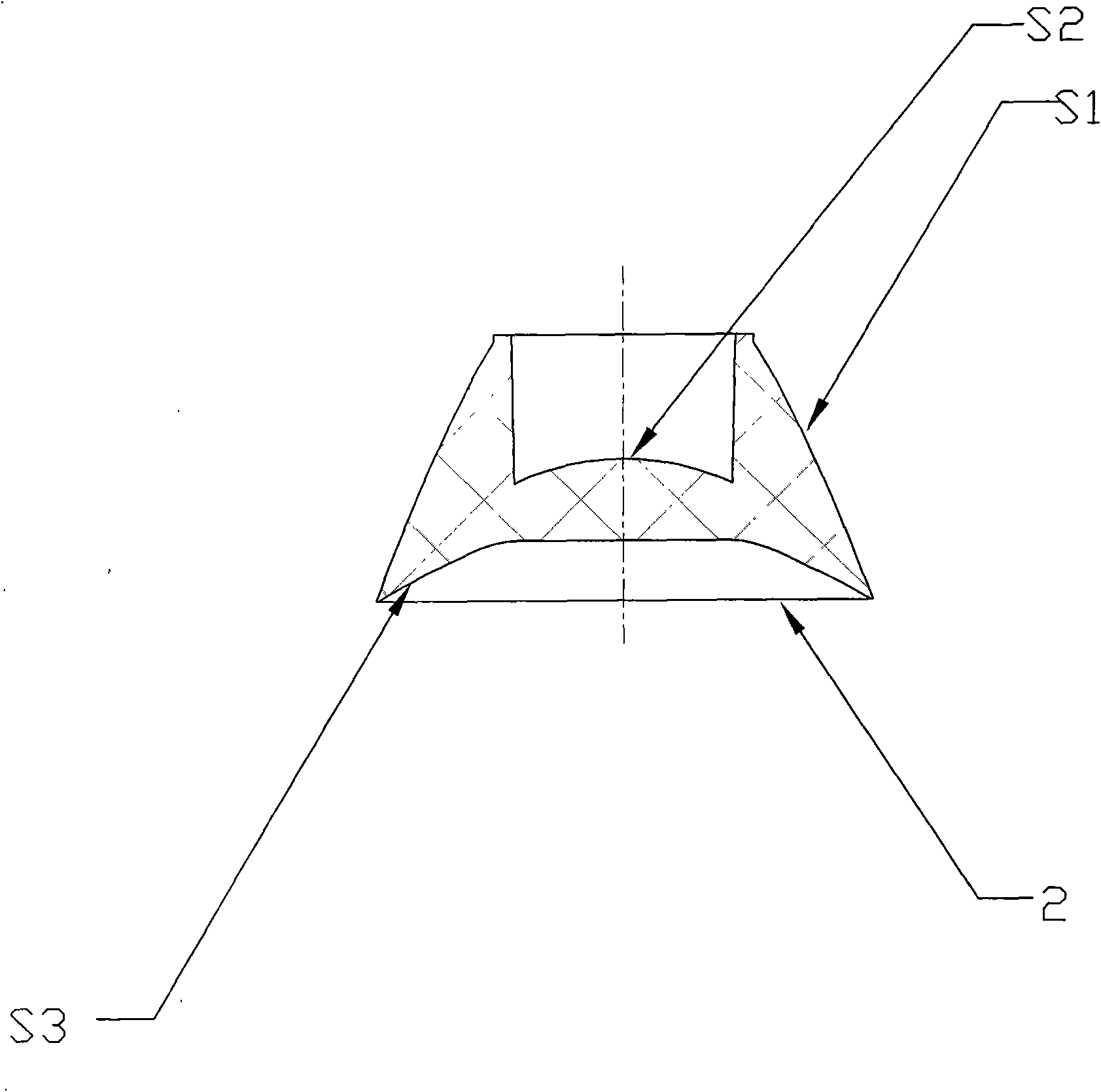

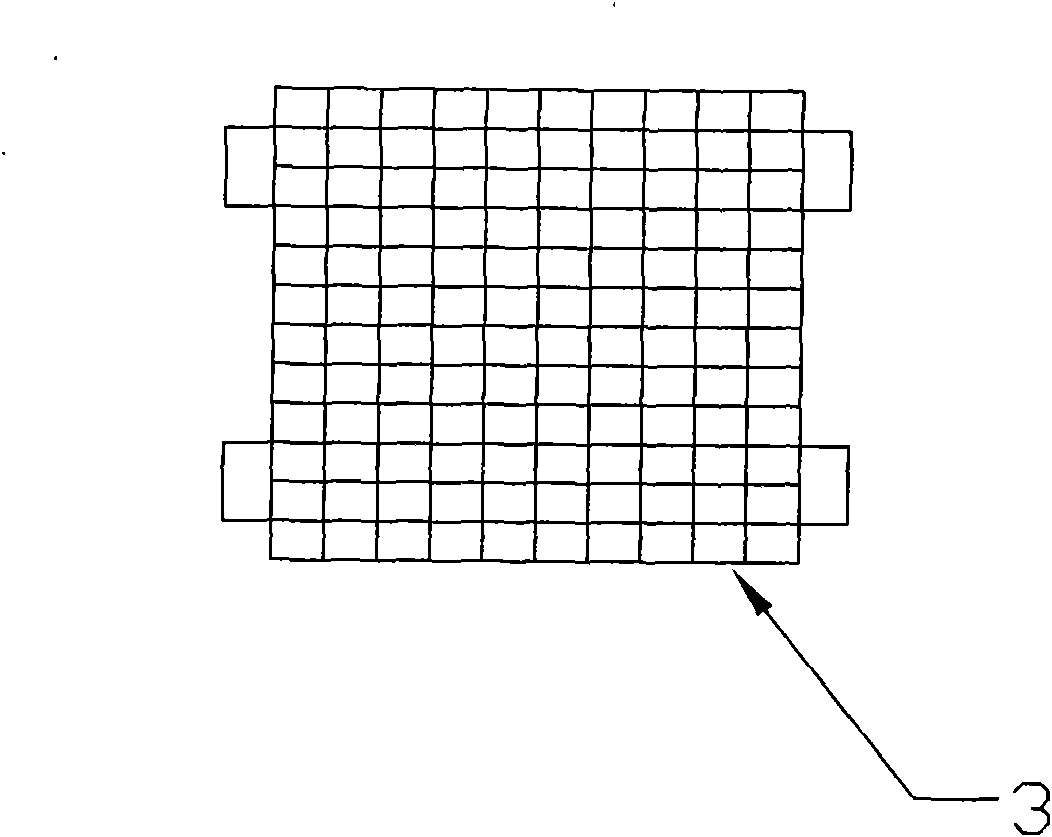

[0043] exist Figure 1 to Figure 5Among them, a projection light source and its projection engine include a single RGB multi-chip LED, a collection of color-combining plastic lenses, a fly-eye lens array, a collimating mirror, a PBS prism, and an imaging device LCOS screen; in a single RGB multi-chip LED, As a light source in the projection optical engine, the three-primary color light emitted by a single RGB multi-chip LED is the main one, and the mixed light beam supplemented by the colored light reaches the fly-eye lens array, which subdivides the discrete light beams emitted by different LEDs into tens to hundreds of small Beam, the collimating mirror changes the optical axis of each small beam to the center of the LCOS screen, so that each small beam is superimposed on the LCOS screen one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com