Sodium rechargeable battery

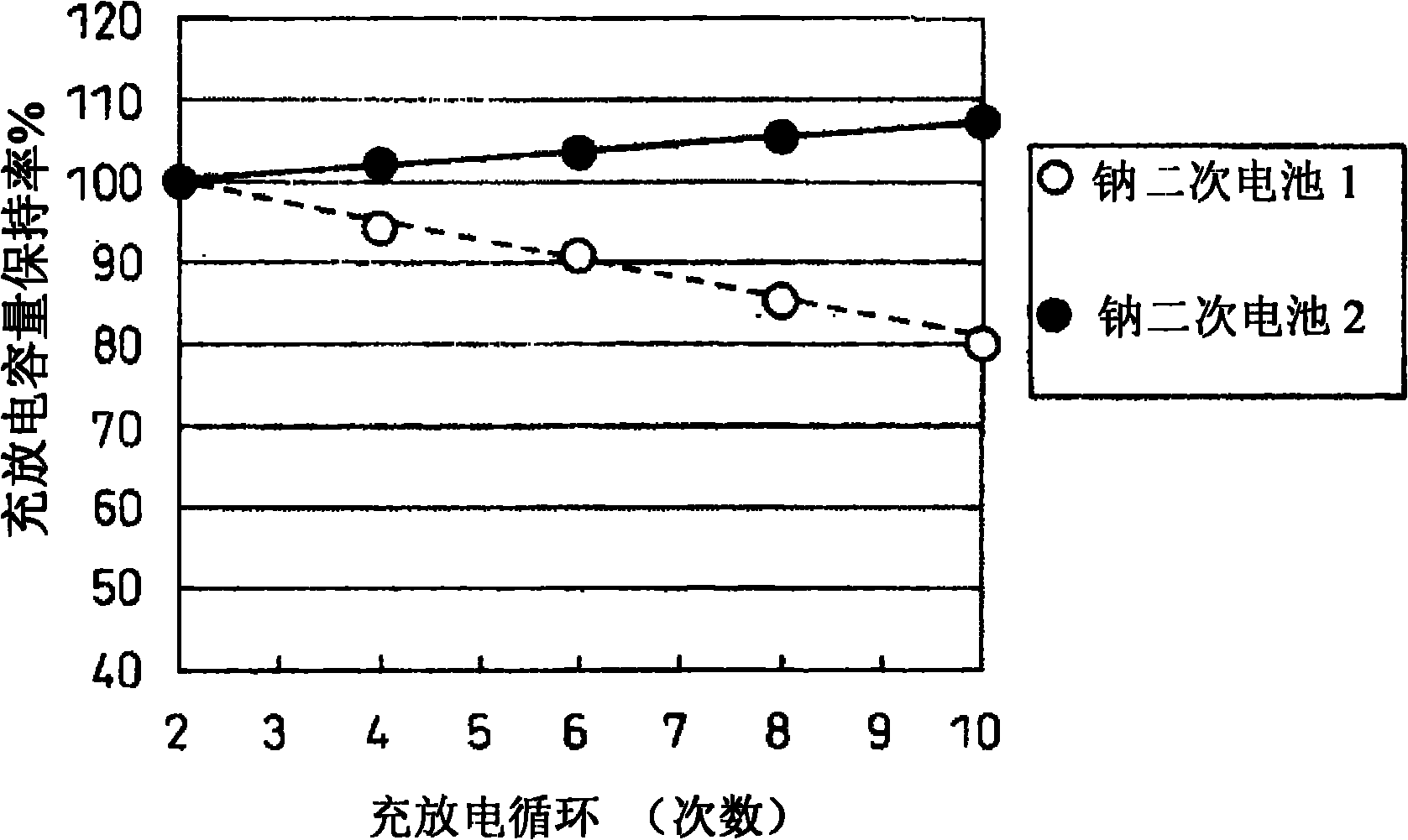

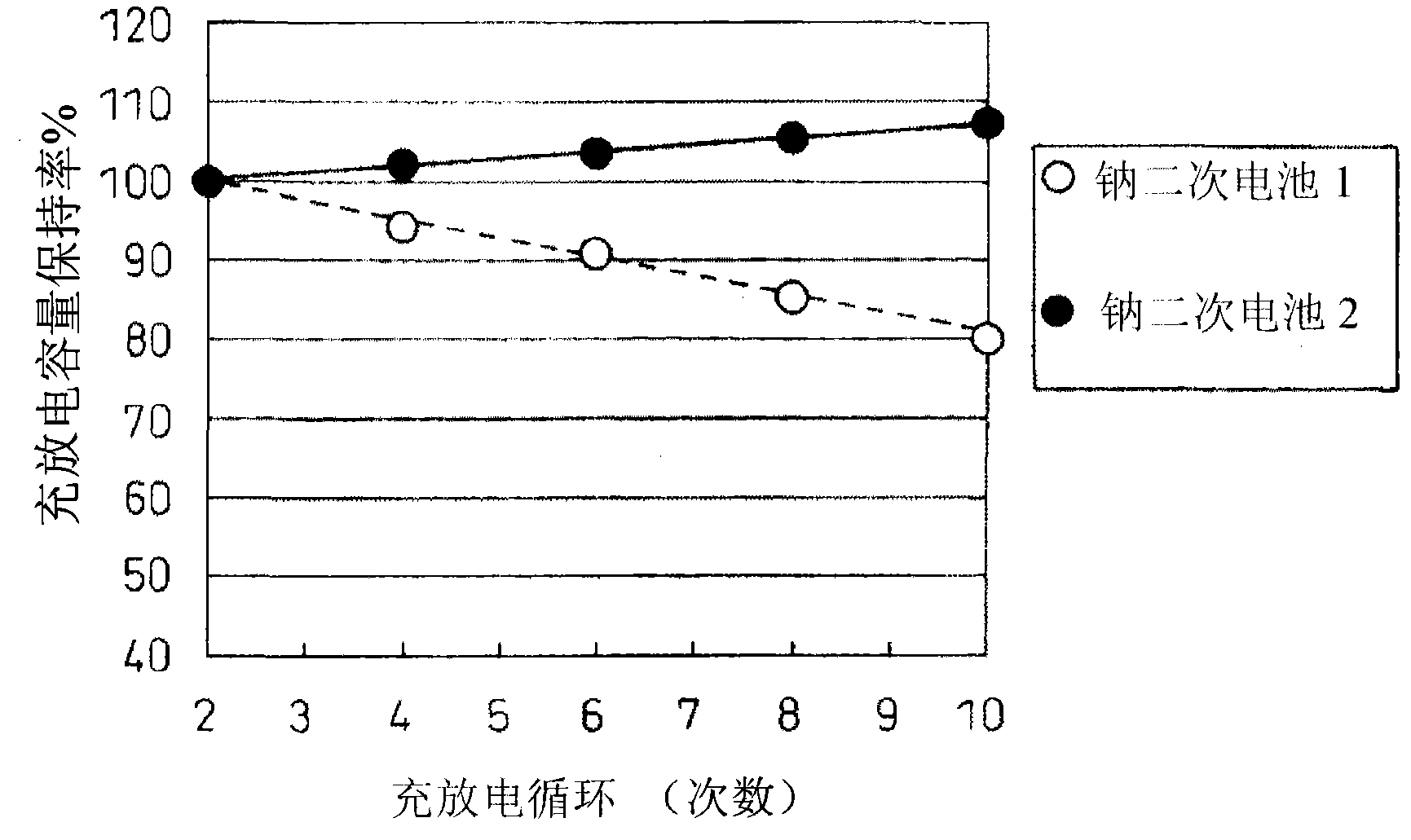

A sodium secondary battery and electrolyte technology, which is applied in the direction of secondary batteries, battery electrodes, battery components, etc., can solve problems such as increased demand and concerns about raw material supply, and achieve reduced usage, high discharge capacity retention, and Excellent circulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0077] Sodium carbonate (Na 2 CO 3 : Manufactured by Wako Pure Chemical Industries, Ltd.: 99.8% purity), manganese (IV) oxide (MnO 2 : Manufactured by High Purity Chemical Research Institute Co., Ltd.: 99.9% purity) and tricobalt tetroxide (Co 3 O 4 : produced by Justsam Chemical Industry Co., Ltd.: purity: 99%), weighed with a molar ratio of Na: Mn: Co of 0.7: 0.5: 0.5, and mixed for 4 hours with a dry ball mill to obtain a metal-containing compound mixture. The resulting metal compound-containing mixture was filled in an alumina boat, heated in an air atmosphere using an electric furnace, and kept at 800° C. for 2 hours to obtain composite metal oxide E1. Composite metal oxide E1, acetylene black as a conductive material (manufactured by Denki Kagaku Kogyo Co., Ltd.), and PVDF as a binder (manufactured by Kleha Co., Ltd., PolyvinylidenDiFluoridePolyflon) are combined according to the composition The metal oxide E1:conductive material:binder=85:10:5 (weight ratio) was we...

Embodiment 1

[0085] (1) Manufacture of carbon materials

[0086] Under a nitrogen stream, 200 g of resorcinol, 1.5 L of methanol, and 194 g of benzaldehyde were added to a four-necked flask, and the flask was cooled, and 36.8 g of 36% hydrochloric acid was added dropwise with stirring. After the titration was completed, the temperature was raised to 65°C, and then kept at a constant temperature for 5 hours. 1 L of water was added to the obtained polymerization reaction mixture, the precipitate was filtered off, the filtrate was neutralized, washed with water, and dried to obtain an organic polymer compound tetraphenylcalix[4]resorcinol arene (テトラフエニル). カリツクス[4] レゾルシナレ一ン) (PCRA) 294g.

[0087] PCRA was put into the rotary kiln, the atmosphere was set to air atmosphere, heated at 300° C. for 1 hour, and then the atmosphere of the rotary kiln was replaced with argon, and heated at 1000° C. for 4 hours. Next, the carbon material C1 as an organic polymer compound sintered body was obtained by ...

Embodiment 2

[0094] (1) Manufacture of positive electrode

[0095] Sodium carbonate (Na 2 CO 3 : Wako Pure Chemical Industries, Ltd.: purity 99.8%), manganese oxide) (IV) (MnO 2 : Made by High Purity Chemical Laboratory Co., Ltd.: Purity 99.9%), iron oxide (II, III) (Fe 3 O 4 : manufactured by High Purity Chemical Laboratory Co., Ltd.: Purity 99%) and nickel (II) oxide (NiO: manufactured by High Purity Chemical Laboratory Co., Ltd.: purity 99.%) The molar ratio of Na:Mn:Fe:Ni is 0.7 : 0.333: 0.333: 0.333 was weighed and mixed with a dry ball mill for 4 hours to obtain a metal compound-containing mixture. A composite metal oxide E2 was obtained by filling the obtained metal compound-containing mixture into an alumina plate, heating in an air atmosphere using an electric furnace, and maintaining at 800° C. for 2 hours. Composite metal oxide E2, acetylene black (manufactured by Denki Chemical Industry Co., Ltd.) as a conductive material, and PVDF (manufactured by Kuraha Co., Ltd., PolyVi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com