Process for treating wastewater comprising high-concentration ammonium salt and sodium salt

A technology for treating process and wastewater, applied in water/sewage treatment, multi-stage water/sewage treatment, heating water/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

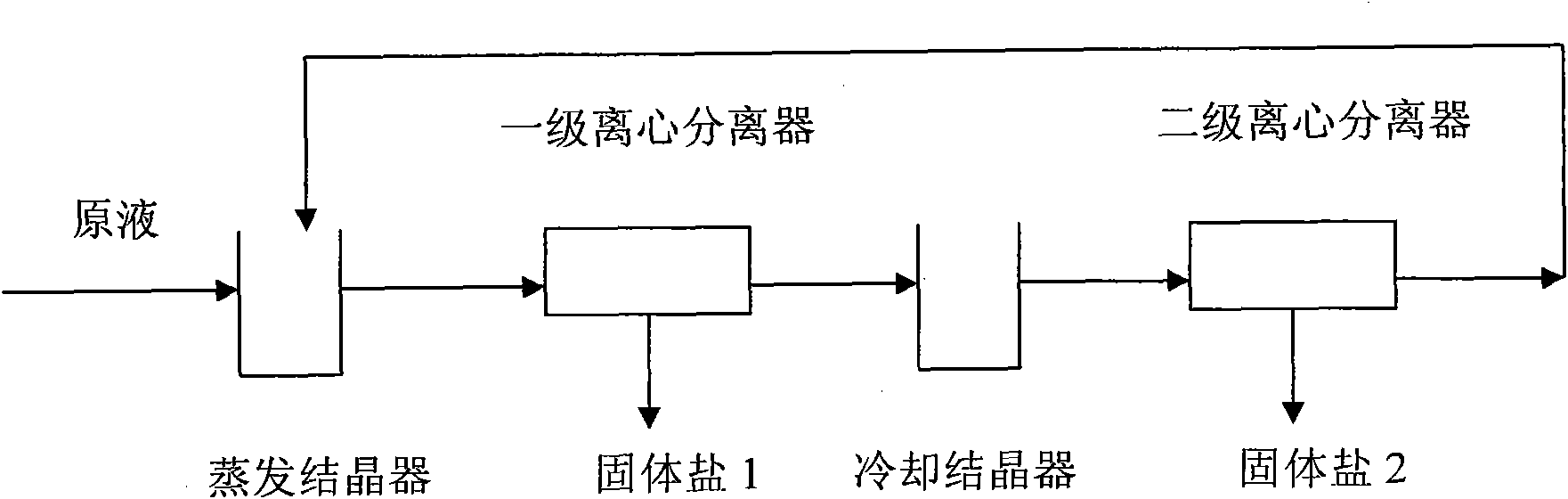

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 Containing sodium salt and ammonium brine evaporation crystallization test

[0042] Test the solubility of sodium chloride, ammonium chloride, ammonium sulfate and sodium sulfate in water, the results are shown in table 1:

[0043] Solubility Table of Table 1 Sodium Salt and Ammonium Salt in Water

[0044]

[0045] Draw the solubility curve according to the data in Table 1. It can be seen that the solubility of ammonium salt increases greatly with the increase of temperature; the solubility of sodium sulfate is the largest at 32.2 ° C, and the solubility slowly decreases when it is greater than 32.2 ° C; the solubility of sodium chloride changes little with temperature .

[0046] According to these features, the applicant designed a set of small-scale experimental equipment, prepared five kinds of solutions as shown in Table 2, and observed the crystallization situation of each salt at high temperature and low temperature when four kinds of salts existe...

Embodiment 2

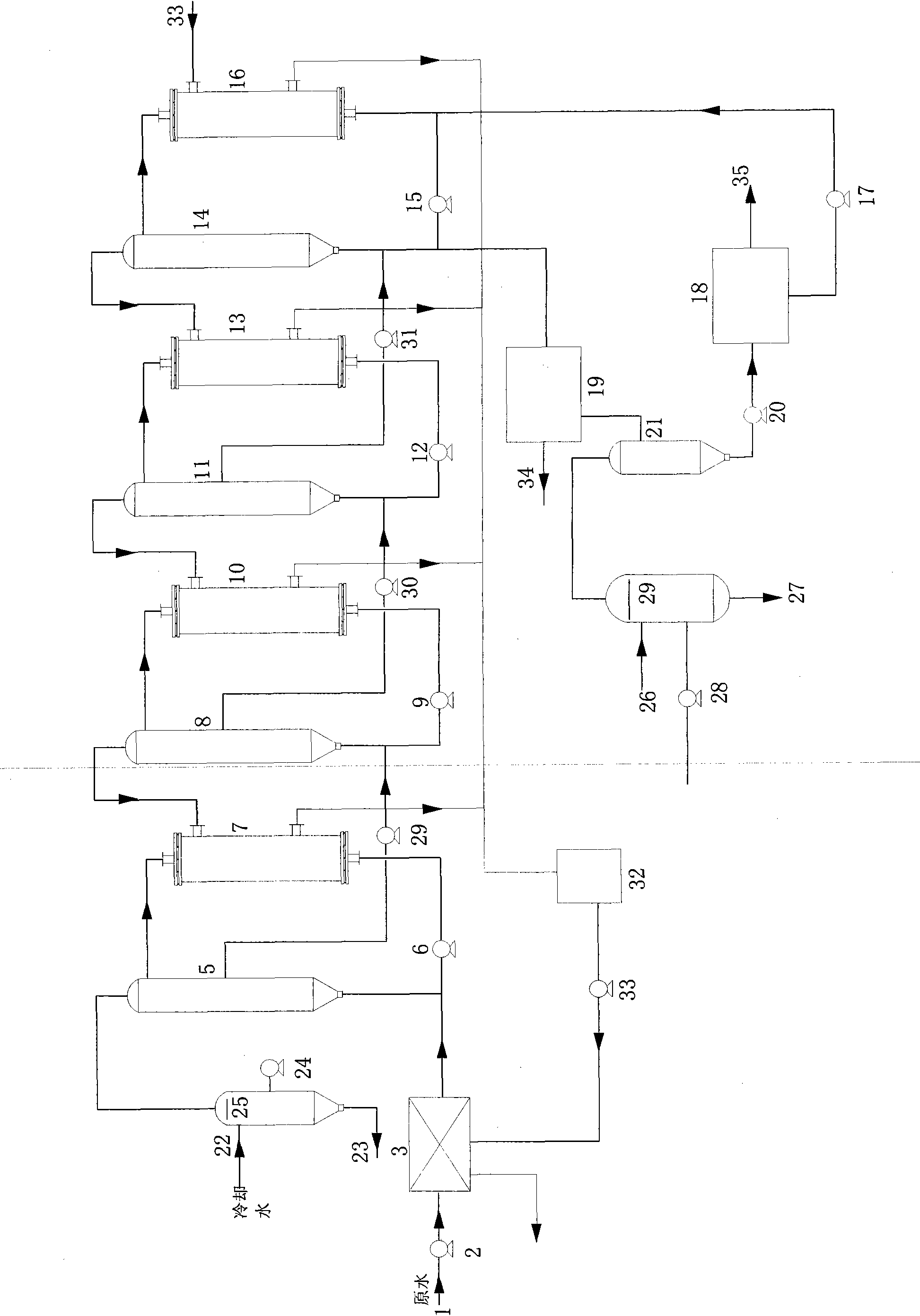

[0054] Such as image 3 As shown, the waste water treatment system containing ammonium salt and sodium salt of the present invention adopts a four-effect evaporation system. The wastewater treatment process is as follows:

[0055] The pretreated raw water 1 is sent to the preheater 3 by the preheat pump 2 for preheating, and the heat source 32 of the preheater 3 comes from the evaporation condensate of each effect. Circulation pump 6, evaporator 5 and heat exchanger 7 form the fourth effect evaporation system. The waste water from preheater 3 is forced to circulate through heat exchanger 7 by circulation pump 6 and then enters evaporation chamber 5 after being heated up, where the solution evaporates in evaporation chamber 5. After concentration, the circulation pump 6 continuously circulates and heats to evaporate and concentrate. The overflow part of the evaporation chamber is sent to the previous effect evaporation and concentration system by the pump 29. The vacuum pump...

Embodiment 3

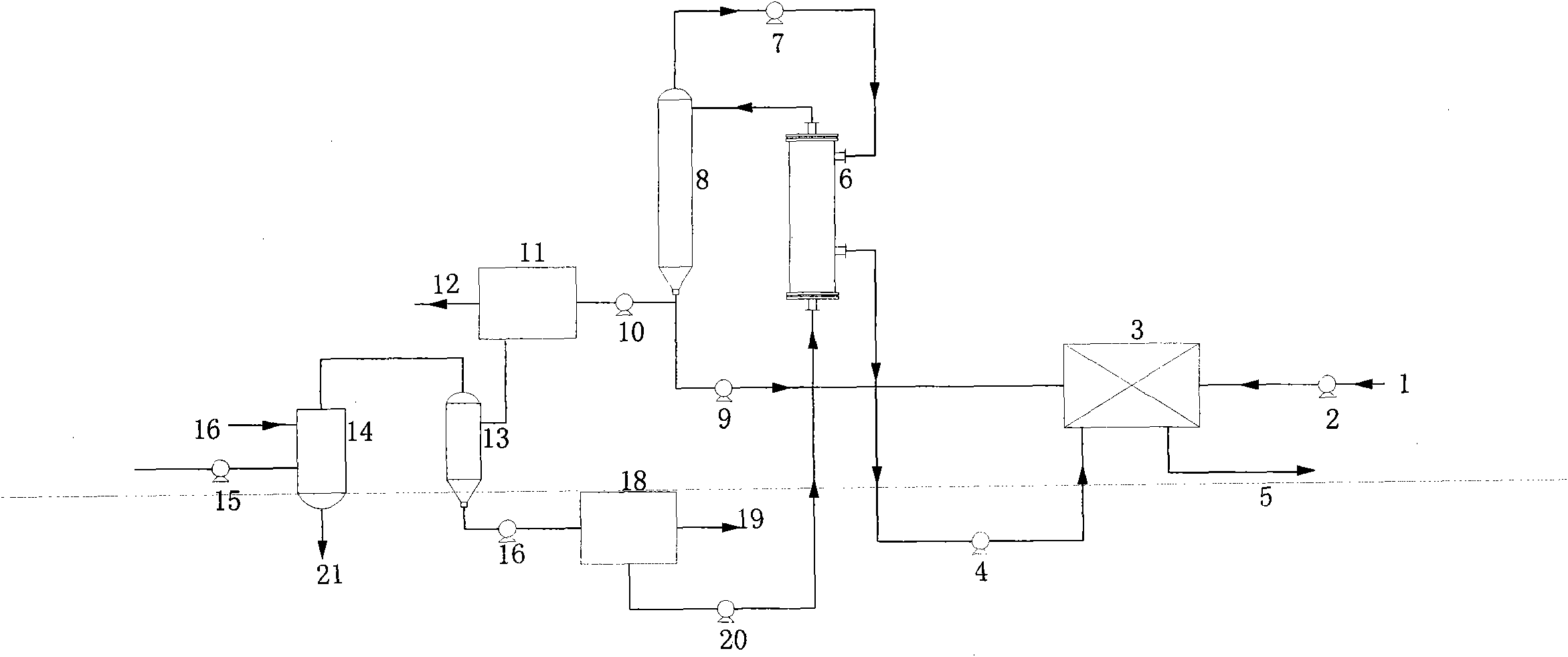

[0063] Such as figure 2 Shown: the waste water treatment system containing ammonium salt and sodium salt of the present invention adopts a vapor compression heat pump type evaporation system. The wastewater treatment process is as follows:

[0064] The pretreated raw water 1 is sent to the preheater 3 by the preheat pump 2 for preheating, and the heat source of the preheater 3 is supplied by the condensate pump 4, and the condensate 5 after cooling can be reused in the production system.

[0065] The circulation pump 9, the heat exchanger 6, the evaporation chamber 8 and the vapor compression heat pump 7 form an evaporation concentration system. The waste water from the preheater 3 enters the evaporation chamber 8, and is forced to circulate through the heat exchanger 6 to be heated by the circulation pump 9. After heating, the solution circulates into the evaporation chamber 8 to evaporate, concentrate and crystallize. The heat pump 7 compresses and heats up the evaporatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com