Composite method of liquid crystal supermolecule material containing double photosensitive units

A synthetic method and supramolecular technology, applied in the field of photosensitive materials, can solve problems such as difficult, poor mechanical properties and thermal stability of azo small molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

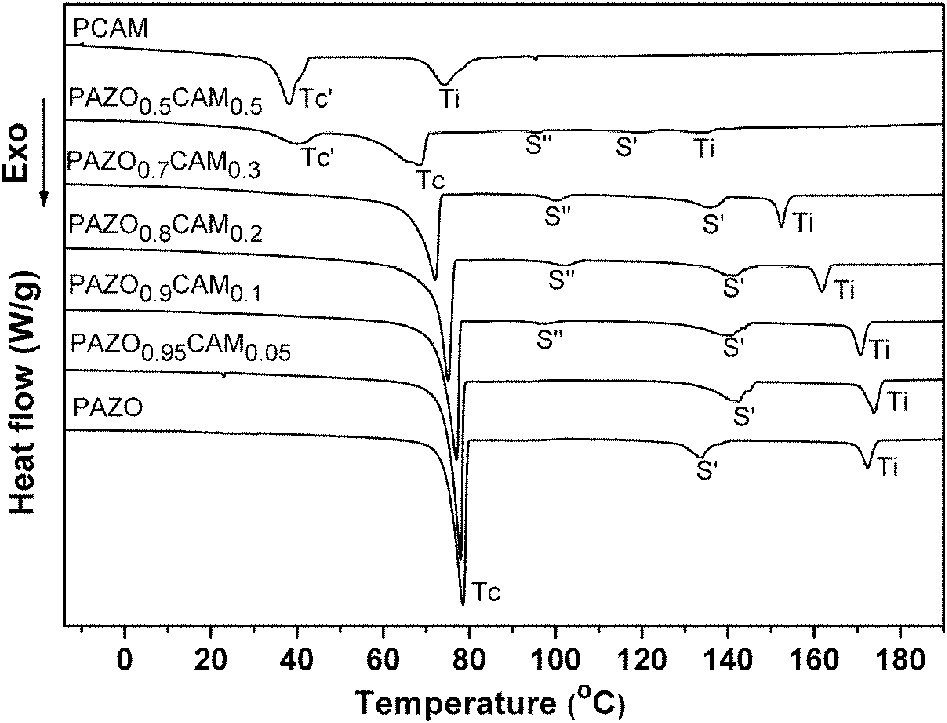

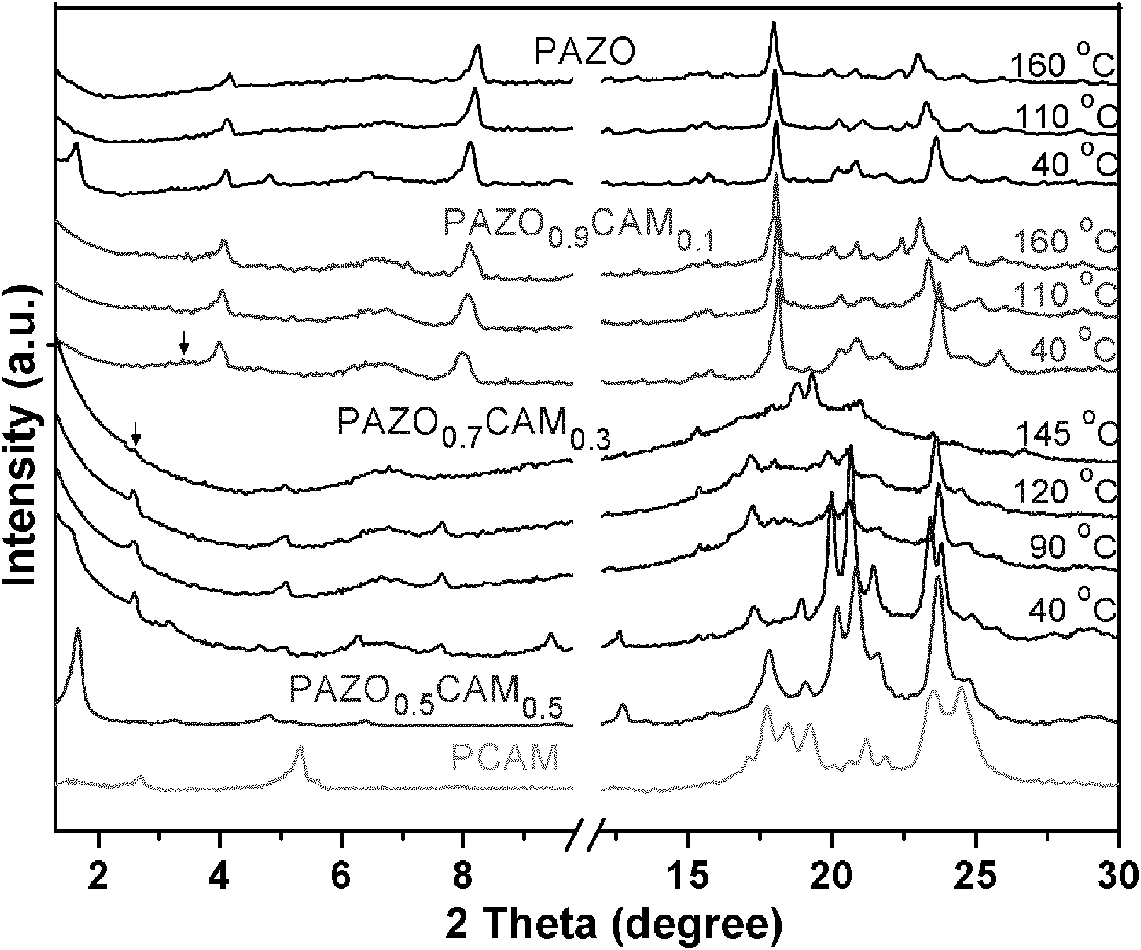

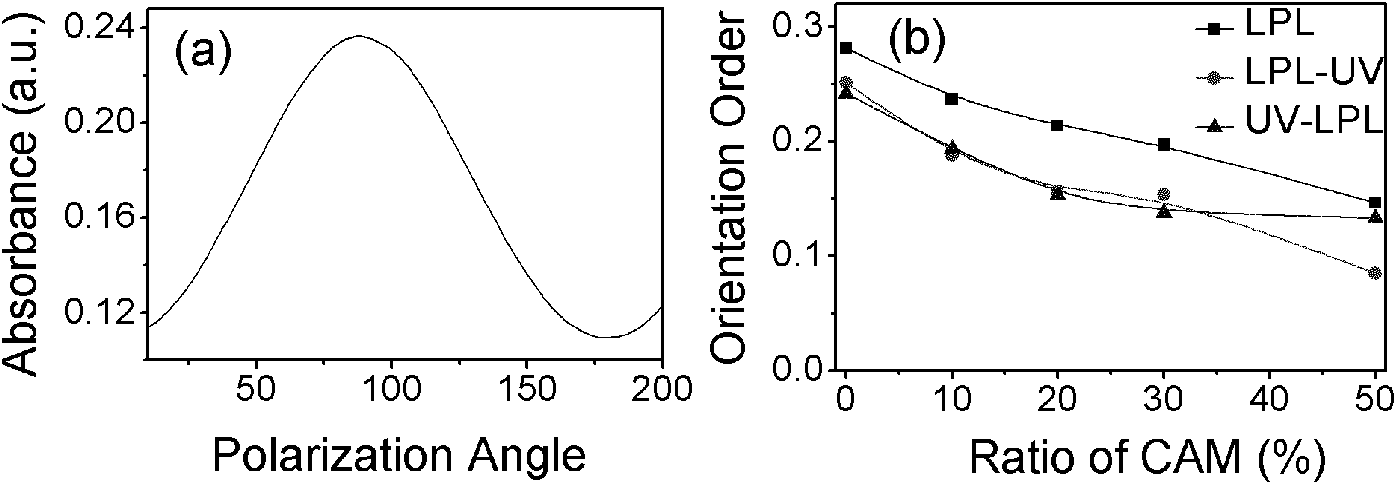

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh azo ionic liquid crystals (AZO) and cinnamic acid ionic liquid crystals (CAM) and dissolve them in water or polar solvents. The molar ratio (AZO:CAM) of the two ionic liquid crystals is 9:1. Stir to make it dissolve completely, the concentration of ionic liquid crystal is 1g / L.

[0026] The structural formula of the azo ion liquid crystal is:

[0027] The structural formula of described cinnamic acid ion liquid crystal is:

[0028] (2) Weigh sodium polyacrylate and dissolve it in water or a polar solvent, stir at room temperature to dissolve completely, and the solution concentration is 10g / L. Sodium polyacrylate molecular weight: 5000-1000000.

[0029] (3) The sodium polyacrylate solution prepared in step (2) is added dropwise in the violently stirred ionic liquid crystal solution, and the amount dropped is determined by calculating the molar positive and negative charge ratio of 1: 1; Stirring was continued at 80°C for 2 hours, then cooled to room tem...

Embodiment 2

[0036] (1) Weigh azo ionic liquid crystals (AZO) and cinnamic acid ionic liquid crystals (CAM) and dissolve them in water or polar solvents. The molar ratio (AZO:CAM) of the two ionic liquid crystals is 8:2. Stir to make it dissolve completely, the concentration of ionic liquid crystal is 1g / L.

[0037](2) Weigh sodium polyacrylate and dissolve it in water or a polar solvent, stir at room temperature to dissolve completely, and the solution concentration is 10g / L. Sodium polyacrylate molecular weight: 5000-1000000.

[0038] (3) The sodium polyacrylate solution prepared in step (2) is added dropwise in the violently stirred ionic liquid crystal solution, and the amount dropped is determined by calculating the molar positive and negative charge ratio of 1: 1; Stirring was continued at 80°C for 2 hours, then cooled to room temperature.

[0039] (4) The assembly product was separated by suction filtration with a 0.45 μm microporous membrane, and the product was washed with water...

Embodiment 3

[0041] (1) Weigh azo ionic liquid crystals (AZO) and cinnamic acid ionic liquid crystals (CAM) and dissolve them in water or polar solvents. The molar ratio (AZO:CAM) of the two ionic liquid crystals is 7:3. Stir to make it dissolve completely, the concentration of ionic liquid crystal is 1g / L.

[0042] (2) Weigh sodium polyacrylate and dissolve it in water or a polar solvent, stir at room temperature to dissolve completely, and the solution concentration is 10g / L. Sodium polyacrylate molecular weight: 5000-1000000.

[0043] (3) The sodium polyacrylate solution prepared in step (2) is added dropwise in the violently stirred ionic liquid crystal solution, and the amount dropped is determined by calculating the molar positive and negative charge ratio of 1: 1; Stirring was continued at 80°C for 2 hours, then cooled to room temperature.

[0044] (4) The assembly product was separated by suction filtration with a 0.45 μm microporous membrane, and the product was washed with wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com