Agrobacterium ZX09, water-soluble beta-glucan prepared from Agrobacterium ZX09 and preparation method thereof and application on reducing blood sugar

A technology of Agrobacterium and strains, applied in the field of Agrobacterium sp.ZX09, which can solve the problems of increased production cost, increased difficulty of β-glucan, and restrictions on large-scale use, and achieves low cost, simple extraction method, and unique properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

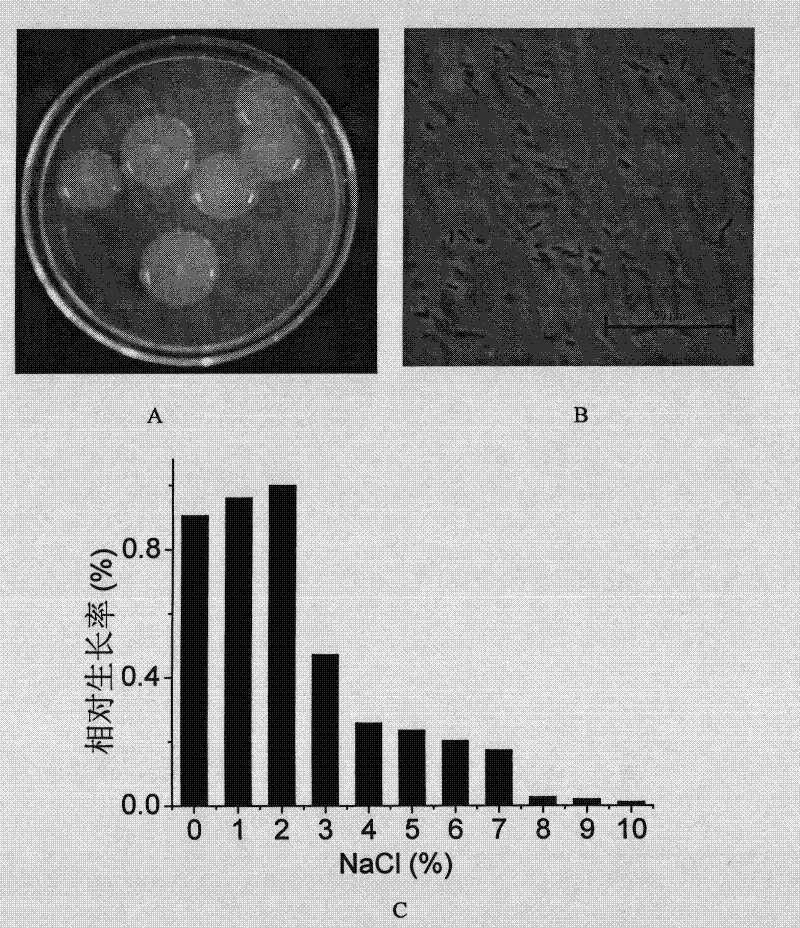

Embodiment 1

[0053] Prepare culture medium, NaH 2 PO 4 0.5g, KNO 3 2g, CaCl 2 0.07g, MgCl 2 0.2g, FeSO 4 ·7H 2 O 0.005g, MnSO 4 0.001g, ZnCl 2 0.005g, sucrose 20g, H 2 O1000mL, pH 5.0. The culture solution was sterilized by heating at 121°C for 15 minutes, cooled to 30°C, inoculated with 200 μL of colony liquid on a plate, and incubated at 28°C for 24 hours to form a seed solution. Add 2% seed culture solution to the culture solution that has been sterilized (sterilized at 121° C. for 15 minutes) and cooled to 30° C., and fermented at 28° C. for 48 hours. Two times the volume of ethanol was added to the fermentation broth to obtain crude β-glucan.

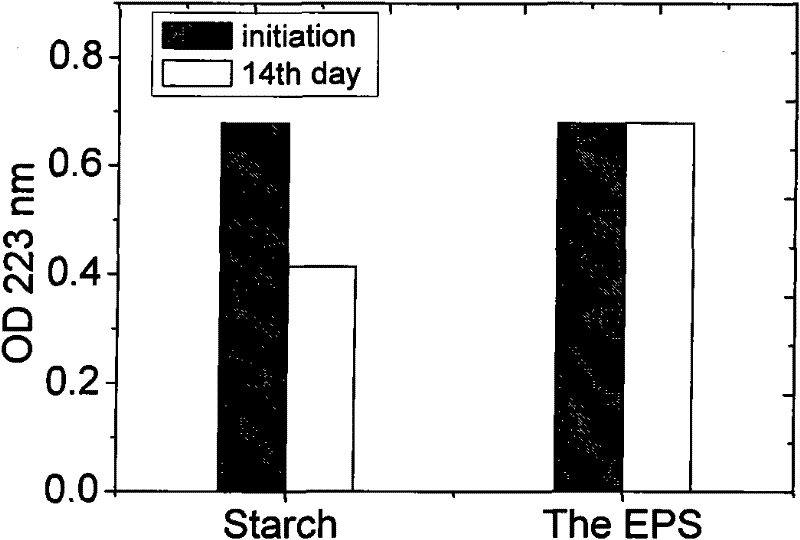

[0054] Mice fasted for 15 hours were directly fed polysaccharide 200mg / kg -1 Or feed polysaccharide mixed with starch 200mg / kg -1 , can effectively control the rise of blood sugar after meals.

Embodiment 2

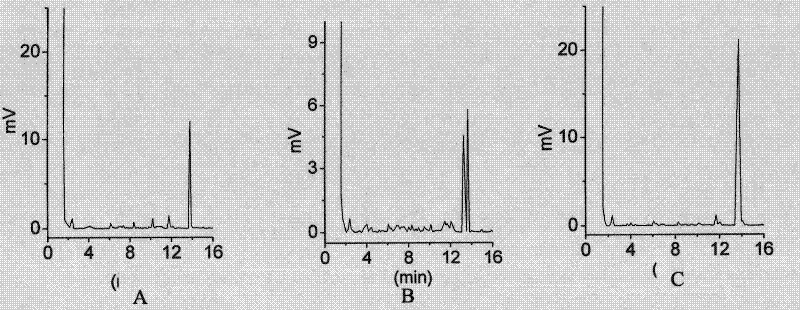

[0056] Prepare culture medium, NaH 2 PO 4 0.5g, KNO 3 2g, CaCl 2 0.07g, MgCl 2 0.2g, FeSO 4 ·7H 2 O 0.0075g, MnSO 4 0.002g, ZnCl 2 0.005g, NaCl 20g, sucrose 20g, H 2 O1000mL, pH 7.2. The culture solution was sterilized by heating at 121°C for 15 minutes, cooled to 30°C, inoculated with 100 μL of colony liquid on a plate, and incubated at 28°C for 24 hours to form a seed solution. Add 10% seed culture solution to the culture solution that has been sterilized (sterilized at 121° C. for 15 minutes) and cooled to 30° C., and fermented at 28° C. for 72 hours. Add twice the volume of 95% ethanol to the fermentation broth to obtain a precipitate which is crude polysaccharide, take out the precipitate, redissolve it in water, and use the sevag method to remove protein three times. Add 2 volumes of ethanol to the deproteinized supernatant to precipitate polysaccharides, and redissolve the precipitate in water. The obtained polysaccharide aqueous solution is separated b...

Embodiment 3

[0058] Prepare culture medium, NaH 2 PO 4 1.0g, KNO 3 2.5g, CaCl 2 0.07g, MgCl 2 0.2g, FeSO 4 ·7H 2 O 0.0075g, MnSO 4 0.002g, ZnCl 2 0.005g, NaCl 20g, sucrose 30g, H 2 O1000mL, pH 7.2, heat the culture solution at 121°C to sterilize for 15 minutes, cool to 30°C, insert 200μL of plate colony liquid, and incubate at 30°C for 24h to form a seed solution. Add 4% seed culture solution to the culture solution that has been sterilized (sterilized at 121° C. for 15 minutes) and cooled to 30° C., and fermented at 28° C. for 48 hours. Add twice the volume of 95% ethanol to the fermentation broth to obtain a precipitate, which is the crude product, take out the precipitate, redissolve it in water, and use the sevag method to remove protein three times. Add 2 volumes of ethanol to the deproteinized supernatant to precipitate polysaccharides, and redissolve the precipitate in water. The obtained polysaccharide aqueous solution is separated by DEAE-32 cellulose and Sepharose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com