Biological modification method of dacron fabrics

A polyester fabric, biological modification technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high crystallinity and glass transition temperature, and the modification effect is not obvious, and achieve obvious effects, The effect of ingenious design and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

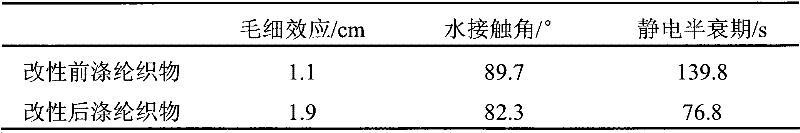

Embodiment 1

[0032] Using 1g / L terephthalic acid as the induction substrate, Comamonas testosteroni was used to biomodify the polyester fabric.

[0033]Cultivate Comamonas testosteroni in a slant solid medium at 30°C for 12 hours, and store it in a refrigerator at 4°C for later use; prepare 6 parts of 150ml polyester modified polyester with a terephthalic acid concentration of 1g / L according to the composition of the liquid medium. and put them into 500ml Erlenmeyer flasks, wrap and sterilize (121°C, sterilize for 25 minutes), and cool down for later use; put 6 parts of polyester fabrics to be modified in a sterile operating table, sterilize with ultraviolet light for 0.5h, and wait for use; transfer the bacteria in the slant culture medium to 3 parts of the prepared polyester modified solution; add 3 parts of the polyester fabric to be modified into the modified solution of 3 parts of the transferred bacteria, and Add 3 parts of fabrics to 3 parts of the modified solution of untransferred...

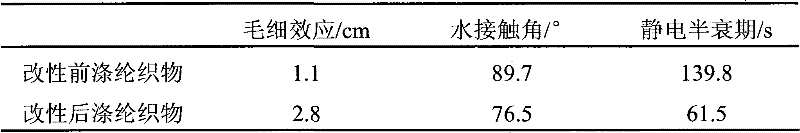

Embodiment 2

[0038] Using 2g / L terephthalic acid as the induction substrate, Comamonas testosteroni was used to biomodify the polyester fabric.

[0039] Cultivate Comamonas testosteroni at 34°C in a slant solid medium for 15 hours, and store it in a refrigerator at 4°C for later use; prepare 6 parts of 150ml polyester modified polyester with a terephthalic acid concentration of 2g / L according to the composition of the liquid medium. and put them into 500ml Erlenmeyer flasks, wrap and sterilize (121°C, sterilize for 25 minutes), and cool down for later use; put 6 parts of polyester fabrics to be modified in a sterile operating table, sterilize with ultraviolet light for 0.5h, and wait for use; transfer the bacteria in the slant culture medium to 3 parts of the prepared polyester modified solution; add 3 parts of the polyester fabric to be modified into the modified solution of 3 parts of the transferred bacteria, and Add 3 parts of fabrics to 3 parts of the modified solution of untransferre...

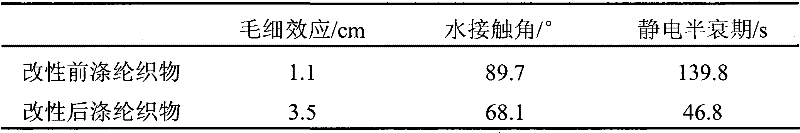

Embodiment 3

[0044] Using 3g / L terephthalic acid as the induction substrate, Comamonas testosteroni was used to biomodify the polyester fabric.

[0045] Cultivate Comamonas testosteroni in a slant solid medium at 37°C for 18 hours, and store it in a refrigerator at 4°C for later use; according to the composition of the liquid medium, prepare 6 parts of 150ml polyester modified polyester with a terephthalic acid concentration of 3g / L and put them into 500ml Erlenmeyer flasks, wrap and sterilize (121°C, sterilize for 25 minutes), and cool down for later use; put 6 parts of polyester fabrics to be modified in a sterile operating table, sterilize with ultraviolet light for 0.5h, and wait for use; transfer the bacteria in the slant culture medium to 3 parts of the prepared polyester modified solution; add 3 parts of the polyester fabric to be modified into the modified solution of 3 parts of the transferred bacteria, and Add 3 parts of fabrics to 3 parts of the modified solution of untransferre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com