Improved structure of discharge mechanism of turndown type fermented soybean meal drying machine

A technology for fermenting soybean meal and improving structure, applied in the field of improving mechanism, can solve the problems of long discharge time, complexity, affecting the conveying speed, etc., and achieve the effect of fast drying and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

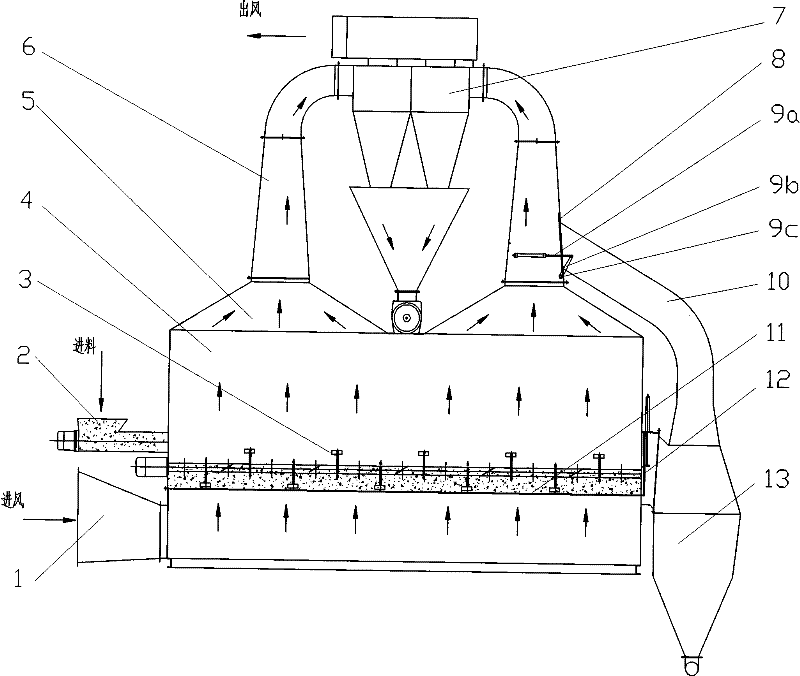

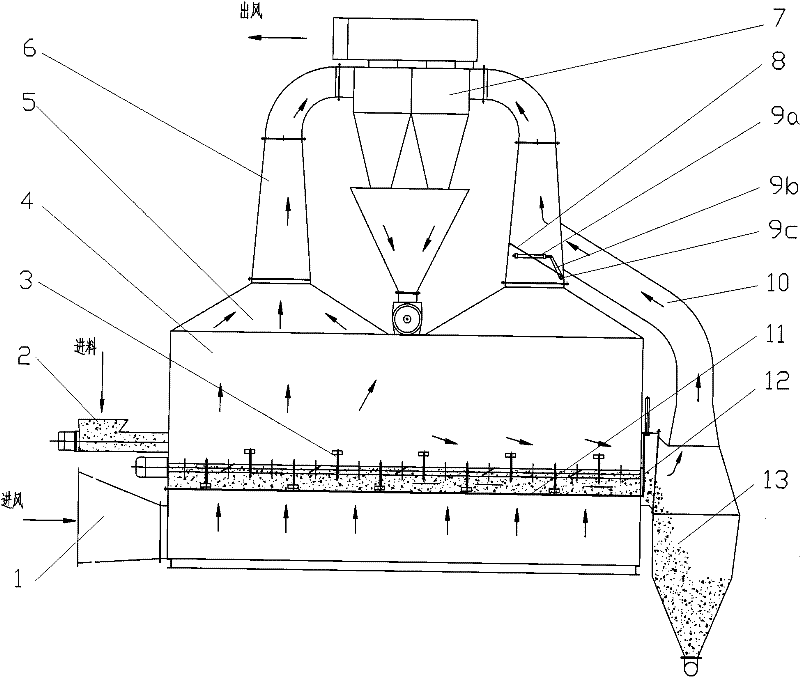

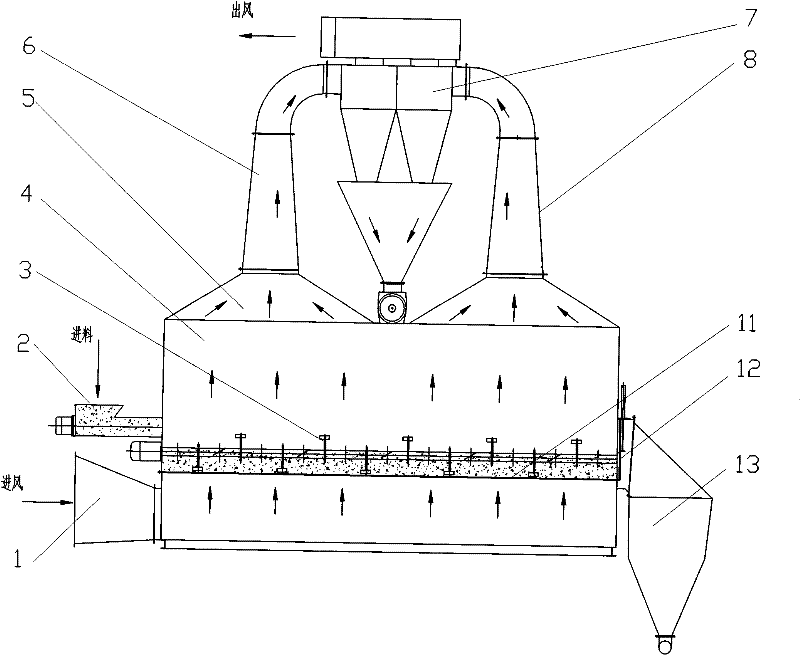

[0037] The present invention will be further described below with reference to the accompanying drawings.

[0038] An improved structure of the discharge mechanism of a turning-type fermented soybean meal dryer, in which a layer of horizontal ventilation hole plate 11 with ventilation holes is arranged in the length direction of the rectangular drying box 4, above the ventilation hole plate 11 , a pair of turning shafts driven by motors are arranged in parallel;

[0039] On both sides of the drying box 4 in the lengthwise direction, above the ventilation orifice 11, a feeding device pushed by the input auger is arranged on one side, and a discharge gate 12 is set on the other side;

[0040] On one side of the feeding device, a hot air inlet 1 is provided at the lower part of the ventilation hole plate 11;

[0041] On the top of the drying box 4, two inverted bucket-shaped air outlet wind collection hoods 5 are arranged in parallel in the length direction, and the two wind col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com