Method for co-producing sodium stannate and stannic oxide by solder removing liquid

A technology of tin dioxide and sodium stannate, applied in the directions of tin oxide, chemical instruments and methods, tin compounds, etc., can solve the problems of high treatment cost of tin stripping solution, complex process and equipment structure, etc. Simple structure, realizing the effect of resource utilization, simple process and equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

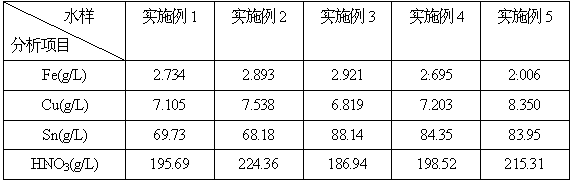

Embodiment 1

[0030] Embodiment 1: A kind of method utilizing tin stripping solution to co-produce sodium stannate and tin dioxide comprises the following steps: A, the tin stripping solution is heated at a temperature of 70°C and a pressure of 0.1×1.03×10 5 Carry out underpressure distillation recovery nitric acid, add Na in the distillate 2 SO 4 , the dosage of electrolyte is 30g / L tin stripping solution, after the sedimentation is completed, press filter, the filter cake is washed and then pressed dry;

[0031] B, neutralize the filtrate and washing solution obtained in step A with alkali, control the pH value of the solution at 6-8, then add sodium sulfide solution until the precipitate no longer generates, filter, the filter cake is copper sulfide, and the filtrate is sent to sewage treatment system;

[0032] C. Put the filter cake obtained in step A into the reactor, add solid NaOH with a molar ratio of 1:2 to the filter cake, heat up to 98°C under stirring, and keep it warm for 2 h...

Embodiment 2

[0035] Embodiment 2: a kind of method utilizing tin stripping solution to co-produce sodium stannate and tin dioxide comprises the following steps:

[0036] A. Put the tin stripping solution at a temperature of 50°C and a pressure of 0.4×1.03×10 5 Carry out underpressure distillation recovery nitric acid under Pa, add Na in distillate 3 PO 4 , Na 3 PO 4 The dosage is 60g / L tin stripping solution. After the sedimentation is completed, press filter, and the filter cake is washed and then dried;

[0037] B, neutralize the filtrate and washing solution obtained in step A with alkali, control the pH value of the solution at 6-8, then add sodium sulfide solution until the precipitate no longer generates, filter, the filter cake is copper sulfide, and the filtrate is sent to sewage treatment system;

[0038]C. Put the filter cake obtained in step A into the reactor, add solid KOH with a molar ratio of 1:3.5 to the filter cake, heat up to 105°C under stirring, and keep it warm fo...

Embodiment 3

[0041] Embodiment 3: a kind of method utilizing tin stripping solution to co-produce sodium stannate and tin dioxide comprises the following steps:

[0042] A. Put the tin stripping solution at a temperature of 60°C and a pressure of 0.3×1.03×10 5 Carry out underpressure distillation to reclaim nitric acid under Pa, add K in the distillate 2 SO 4 , K 2 SO 4 The dosage is 40g / L tin stripping solution. After the sedimentation is completed, press filter, and the filter cake is washed and then dried;

[0043] B, neutralize the filtrate and washing solution obtained in step A with alkali, control the pH value of the solution at 6-8, then add sodium sulfide solution until the precipitation no longer generates, filter, the filter cake is copper sulfide, and the filtrate is sent to sewage treatment system;

[0044] C. Send the filter cake obtained in step A into the reactor, and add solid NH with a molar ratio of 1:3 to the filter cake 3 h 2 O, heat up to 100°C under stirring, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com