Method for treating printing and dyeing wastewater

A technology for printing and dyeing wastewater and a treatment method, applied in the field of water treatment, can solve the problems of large investment in reverse osmosis membrane treatment, high operating cost, unsatisfactory effect of advanced treatment of printing and dyeing wastewater, etc., and achieves stable operation, power saving and investment cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The process flow is as follows:

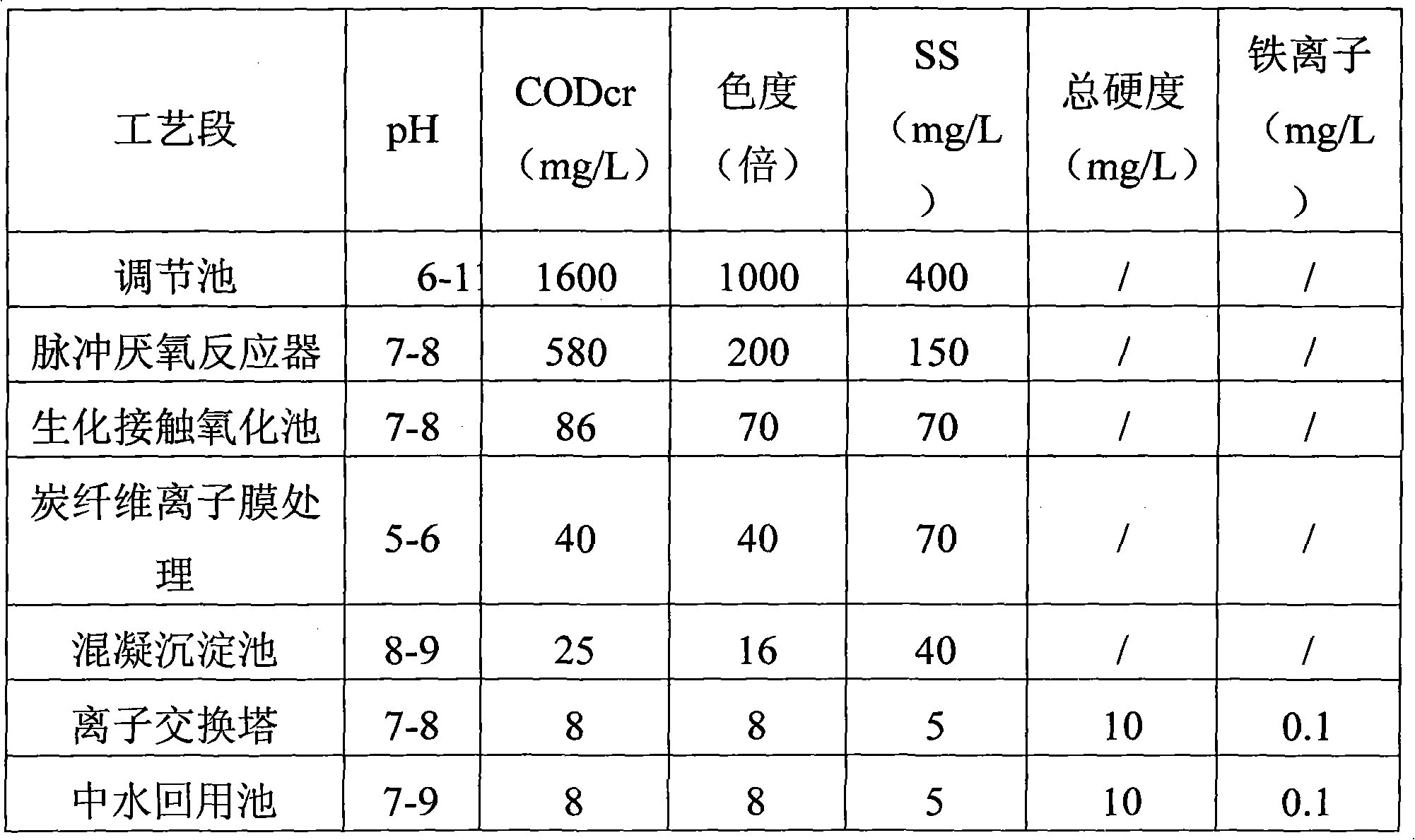

[0022] Waste water → grid → regulating tank → pulse anaerobic reactor → biological contact oxidation tank → secondary sedimentation tank → carbon fiber ion membrane treatment device → coagulation sedimentation tank → intermediate tank → manganese sand filter → precision filter → ion exchange tower →Reclaimed water reuse pool

[0023] The printing and dyeing wastewater is filtered through a 2mm grid to remove impurities with large particles before entering the regulating tank. The wastewater is fully stirred and mixed in the regulating tank to uniform the water quality and quantity, and reduce the pH of the wastewater to within 11. The effluent of the regulating tank is pumped to the pulse anaerobic reactor, and the facultative microorganisms in the activated sludge in the pulse anaerobic reactor acidify and hydrolyze the macromolecular organic matter, degrade the macromolecules into small molecular biochemical substances, and improve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com