Method for producing boron nitride nano tube reinforced and toughened zirconium oxide ceramic

A technology of boron nitride nanotubes and zirconia ceramics, which is applied in the field of boron nitride nanotubes to strengthen and toughen zirconia ceramics, which can solve the problems of high brittleness and poor effect of carbon nanotubes on the strengthening and toughening of zirconia ceramics. Achieve high production efficiency, high product mechanical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

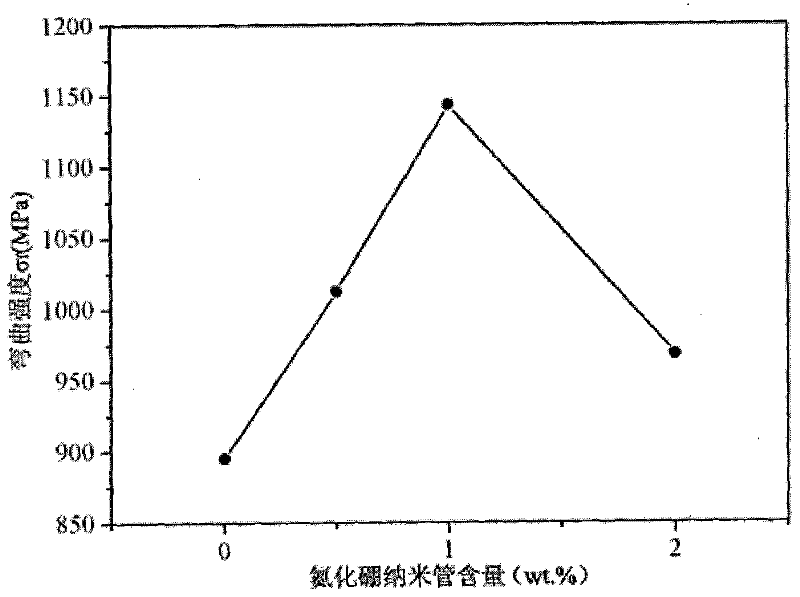

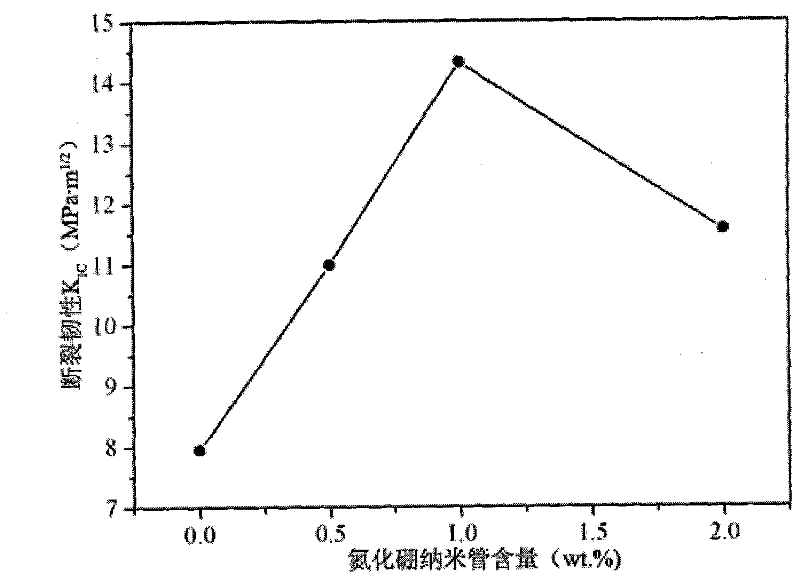

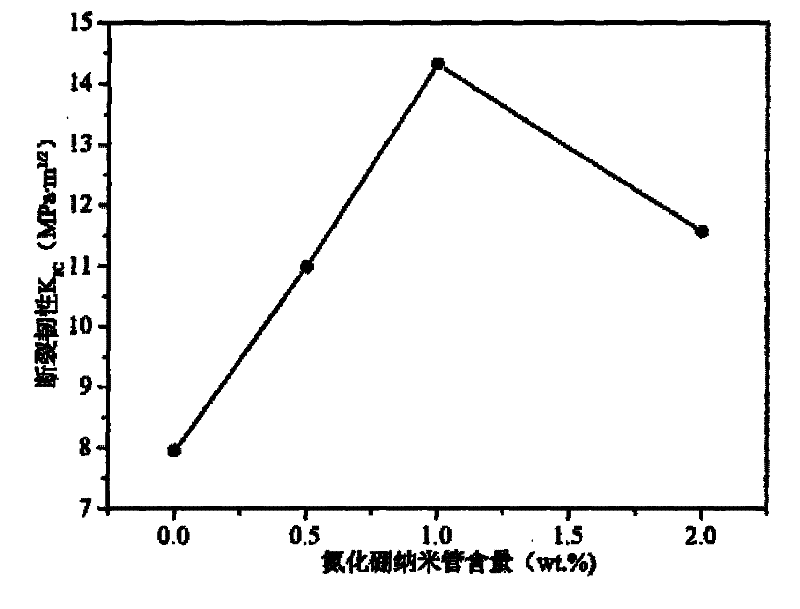

[0024] Example 1: Determination of the trend of flexural strength and fracture toughness of boron nitride nanotube-reinforced and toughened zirconia ceramics with the addition of boron nitride nanotubes

[0025] With boron nitride nanotubes as reinforcement phase, 3Y-ZrO 2 Zirconia ceramics were prepared by hot pressing and sintering as the substrate. The sintering temperature is 1450°C, the sintering time is 2h, and the pressure is 25MPa. After the surface of the sintered sample was ground by a grinder, it was cut into four groups of samples with a size of 3×4×30 mm to measure the bending strength, and four groups of samples with a size of 2×4×30 mm to measure the fracture toughness.

[0026] The bending strength adopts the three-point bending method, and the span is 20mm. On a universal testing machine at a loading speed of 0.5 mm / min, press along the hot pressing direction to measure the flexural strength, and calculate the average value of four groups of samples to obtai...

Embodiment 2

[0029] Embodiment 2: Using boron nitride nanotubes as a reinforcing phase, with 3Y-ZrO 2 Zirconia ceramics were prepared by hot pressing and sintering as the substrate.

[0030] Weigh 0.45g of boron nitride nanotubes, 44.45g of zirconia, and 270g of zirconia grinding balls with a balance, measure 150ml of absolute ethanol with a graduated cylinder, put them into a ball mill jar, and mix them on a planetary ball mill. The rotating speed of the ball mill is 300r / min, and the ball milling time is 12 hours. The mixed slurry after ball milling was dried and sieved, put into an alumina crucible, heated to 400° C. in a muffle furnace and kept for 1 hour for pre-sintering. After cooling, take out the mixed powder, place it in a graphite mold with a diameter of 42mm, heat up to 1450°C in a multifunctional sintering furnace at a rate of 25°C / min, and sinter at a sintering pressure of 25MPa, stop heating after 1 hour of heat preservation, and cool naturally to room temperature . The s...

Embodiment 3

[0031] Embodiment 3: with boron nitride nanotube as reinforcing phase, with 3Y-ZrO 2 Zirconia ceramics were prepared by hot pressing and sintering as the substrate.

[0032] Weigh 0.25g of boron nitride nanotubes, 49.75g of zirconia, and 300g of zirconia grinding balls with a balance, measure 150ml of absolute ethanol with a graduated cylinder, put them into a ball mill jar, and mix them on a planetary ball mill. The rotating speed of the ball mill is 300r / min, and the ball milling time is 12 hours. The mixed slurry after ball milling was dried and sieved, put into an alumina crucible, heated to 400° C. in a muffle furnace and kept for 1 hour for pre-sintering. After cooling, take out the mixed powder, put it in a graphite mold with a diameter of 42mm, heat up to 1450°C in a multifunctional sintering furnace at a rate of 25°C / min, and sinter at a sintering pressure of 25MPa, stop heating after 2 hours of heat preservation, and naturally cool to room temperature . The sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com