Method for preparing biodegradable membrane

A technology for biodegradation and biodegradation of polyester is applied in the field of preparation of biodegradable films, which can solve problems such as soil structure damage and land yield reduction, and achieve the effects of simple production process, improved efficiency and reduced processing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

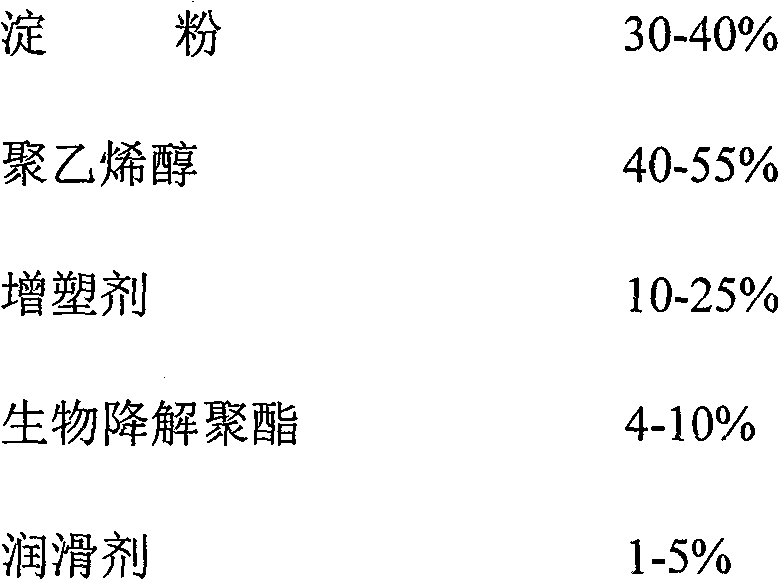

Method used

Image

Examples

Embodiment 1

[0045] 1. Prepare 40 kg of corn starch, 55 kg of polyvinyl alcohol, 6 kg of glycerin, polyglycidyl sebacate-D, 2 kg of L-malic acid, 1 kg of water, 1 kg of stearic acid, and poly 3-hydroxyl Butyrate 5 kg.

[0046] 2. Add corn starch, polyvinyl alcohol, compound plasticizer, lubricant, and biodegradable polyester to the high-speed mixer, and mix well;

[0047] 3. Put the above-mentioned uniformly mixed raw materials into a granulator for mixing, melting, extruding, cooling, and then pelletizing to obtain biodegradable resin pellets for making films;

[0048] 4. Add the biodegradable resin particles obtained in the above steps to a film blowing machine to make a film.

Embodiment 2

[0050] 1. Prepare 30 kilograms of corn starch, 45 kilograms of polyvinyl alcohol, 8 kilograms of glycerin, polyazelaic acid diglycidyl ester-, 5 kilograms of L-malic acid, 2 kilograms of water, 2 kilograms of calcium stearate, and poly 3-hydroxyl Butyrate 8 kg.

[0051] 2. Add starch, polyvinyl alcohol, compound plasticizer, lubricant, and biodegradable polyester into the high-speed mixer, and mix well;

[0052] 3. Put the above-mentioned uniformly mixed raw materials into a granulator for mixing, melting, extruding, cooling, and then pelletizing to obtain biodegradable resin pellets for making films;

[0053] 4. Add the biodegradable resin particles obtained in the above steps to a film blowing machine to make a film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com