Test method for measuring plastic concrete permeability coefficient

A technology of plastic concrete and permeability coefficient, which is applied in the direction of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc. It can solve the problems of instantaneous breakdown, low compressive strength and impermeability, and inability to obtain permeability coefficient, etc. problem, achieve the effect of reducing resistance and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Test method for determining the permeability coefficient of plastic concrete.

[0029] 1.1 Specifications / procedures used in experimental research

[0030] "General Portland Cement" GB175-2007

[0031] "Concrete Admixtures" GB8076-2008

[0032] "Hydraulic Concrete Test Regulations" DL / T5150-2001

[0033] DL / T5151-2001 "Test Regulations for Hydraulic Concrete Sand and Gravel Aggregate"

[0034] DL / T5199-2004 "Code for Construction of Concrete Cutoff Walls in Hydropower and Water Conservancy Regulations"

[0035] "Soil Engineering Test Regulations" SL237-1999

[0036] 1.2 Test materials

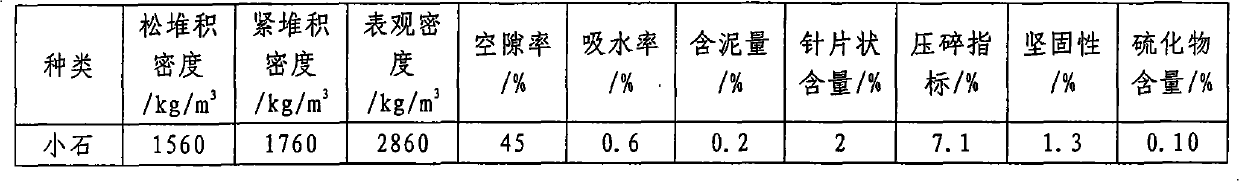

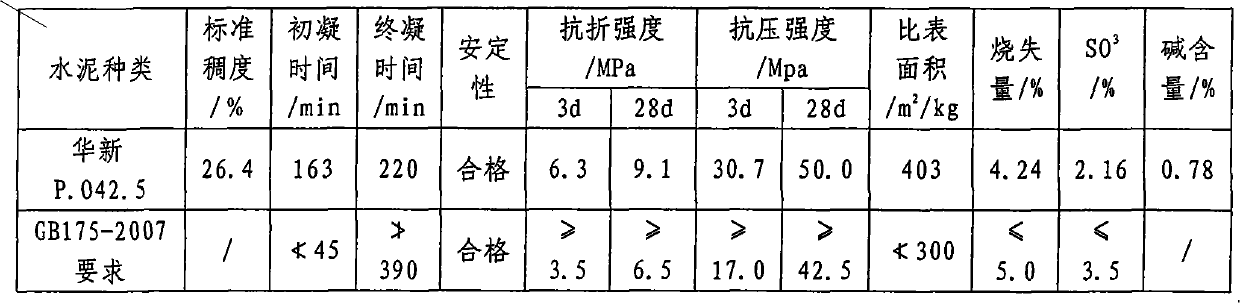

[0037] 1.2.1 Cement

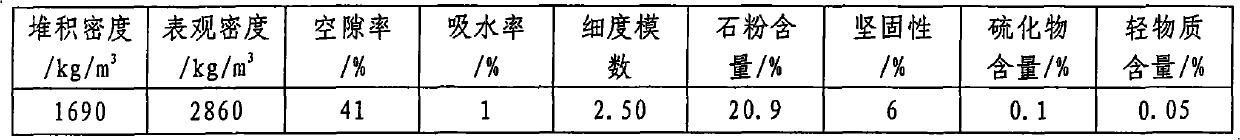

[0038] The technical performance of ordinary Portland 42.5 cement produced for Huaxin Cement Factory is as follows:

[0039] Table 1 Huaxin Ordinary Portland 42.5 Cement Technical Performance

[0040]

[0041] 1.2.2 Clay and bentonite

[0042] The clay is local red clay in Ning'er County, Yunnan Province, which is dried in the sun and passed through a 2m...

Embodiment 2

[0069] Repeat Example 1 with the following differences: when the air temperature is less than 15° C., butter and fly ash are uniformly mixed in a weight ratio of 1:2 as a sealing material.

[0070] Concrete penetration test sealing material requirements are able to resist a certain water pressure without leakage, and have a certain degree of hydrophilicity. The greater the water pressure used, the higher the solid content in the sealing material. The weight ratio of traditional butter and fly ash is 1: ≥ 3, and the sealing material is relatively hard. When entering the mold, the load of ≮20kN will be tested. The piece is pressed into the test mold. The strength of plastic concrete is low, and the mold-in method of ordinary concrete cannot be used. Therefore, the proportion of solids in the sealing material must be reduced to ensure that the specimen can be molded in place with only a small pressure when it is molded, and can be used in the test. No water leakage under the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com